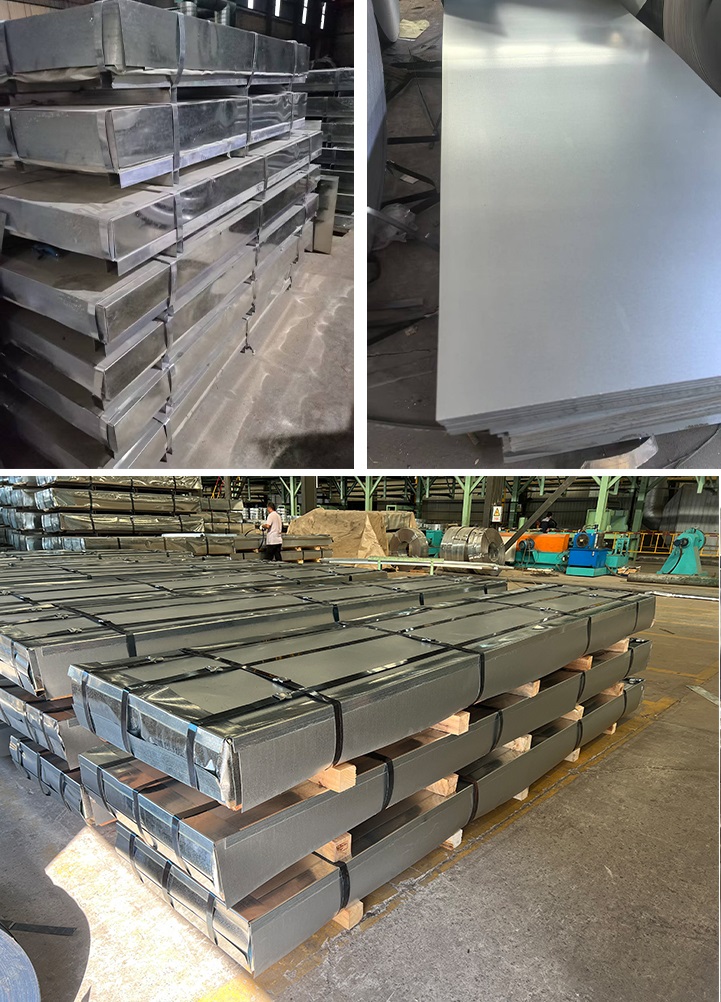

Alibaba Hot-selling galvanized steel sheets – ideal for steel pipe manufacturing

description1

Production description

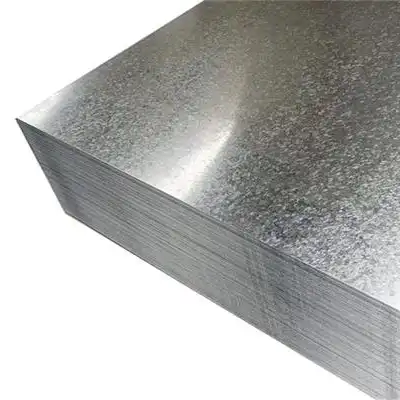

Product name |

Galvanized steel sheet |

Width |

1000mm, 1219mm, 1250mm, 1500mm or according to customer's requirement |

Thickness |

0.12-2.5mm, 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customized |

Length |

customized |

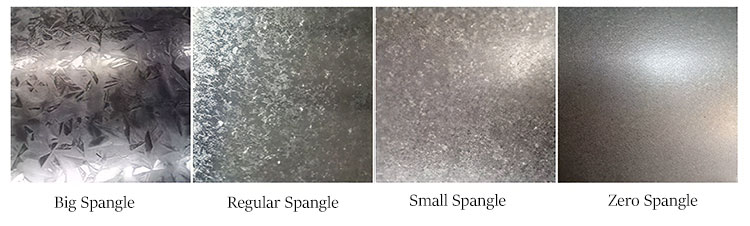

Surface Structure |

Slightly oiled,Galvanized |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Grade |

DC51D+Z,DC52D+Z,DC53D+Z, DX51D+Z, SGCC, SGCD, SGHC, SGH340, DX51D+AZ, DC51D+AZ, DX51D+ZAM, DC51D+ZAM, SECC, DX51D+ZF, DC51D+ZF, CSA, CSB, SS33, S350GD |

Coating Weight |

30-300g/m2 |

Galvanized steel plates are generally produced by opening and cutting galvanized steel coils. Its core advantage lies in a dual protection mechanism: the zinc layer tightly covers the surface of the steel, isolating corrosive media such as water and oxygen; Even if the zinc layer is locally damaged, zinc will preferentially oxidize, sacrificing itself to protect the steel from corrosion and greatly extending its service life. According to different processes, there are two common types: hot-dip galvanizing and electroplating galvanizing. The thickness of hot-dip galvanized zinc layer is usually 30-100 μ m (single-sided), with stronger protective ability, suitable for outdoor buildings, heavy machinery and other scenarios with high weather resistance requirements; Electroplated zinc coating is relatively thin (5-15 μ m single-sided), with a smoother surface, and is commonly used in fields such as home appliance casings and precision components that require a balance between aesthetics and basic protection. In terms of performance, galvanized steel plate combines the strength of steel with the toughness of zinc layer, which can meet various processing needs such as stamping, welding, bending, etc., and the surface state is flexible - it has the unique texture of natural zinc flower, and can also be customized with no flower treatment to meet different appearance requirements.

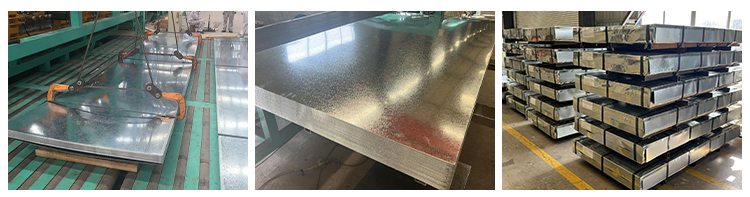

Production Application

Footwear abrasion solutions

Galvanized steel plates are widely used in various fields due to their corrosion resistance, process ability, and economy, mainly concentrated in the following categories:

Construction industry:used for roof and wall enclosure structures (such as color steel tiles), keels, ventilation ducts, etc., resistant to wind and rain erosion, suitable for long-term outdoor use.

Automobile manufacturing: producing body coverings, chassis components, door frames, etc., while balancing structural strength and rust prevention requirements, to extend the service life of vehicles.

In the field of household appliances: as the outer shell and internal structural components of refrigerators, washing machines, air conditioners and other electrical appliances, the surface is smooth and easy to handle, meeting the dual requirements of appearance and protection.

Machinery and equipment manufacturing: used for agricultural machinery components, storage shelves, containers, distribution boxes, etc., resistant to friction and environmental erosion in daily use.

Municipal and infrastructure: such as streetlights, traffic guardrails, underground pipe gallery supports, steel pipes etc., to adapt to complex outdoor environments and reduce maintenance costs.

Its diverse performance combinations make it a universal foundational material across industries.