In the evolving landscape of construction and structural engineering, the quest for enhanced quality and durability has never been more critical, particularly when it comes to pivotal components like the Steel Beam. As noted in the 2022 Annual Global Steel Report, the demand for innovative steel solutions is on the rise, with projections indicating an increase in structural steel consumption by over 4% annually through 2025. This surge reflects the industry's commitment to sustainable development and resilience in infrastructure, where the role of Steel Beams is fundamental.

Recent advancements have introduced novel design methodologies and materials aimed at improving the lifespan and performance of Steel Beams under varying loads and environmental conditions. According to a study published by the International Journal of Structural Engineering, engineers report a 30% enhancement in load-bearing capacity when utilizing advanced composite materials alongside traditional steel. These innovations not only promise greater safety and efficiency but also align with global trends toward minimizing carbon footprints in construction.

As we look towards 2025 and beyond, the top 10 Steel Beam innovations are poised to revolutionize the industry, driving forward a new era of quality and durability that meets and exceeds the rigorous standards set forth by regulatory bodies. This exploration of groundbreaking advancements will highlight the intersection of technology and engineering, ensuring that structures built today will stand the test of time.

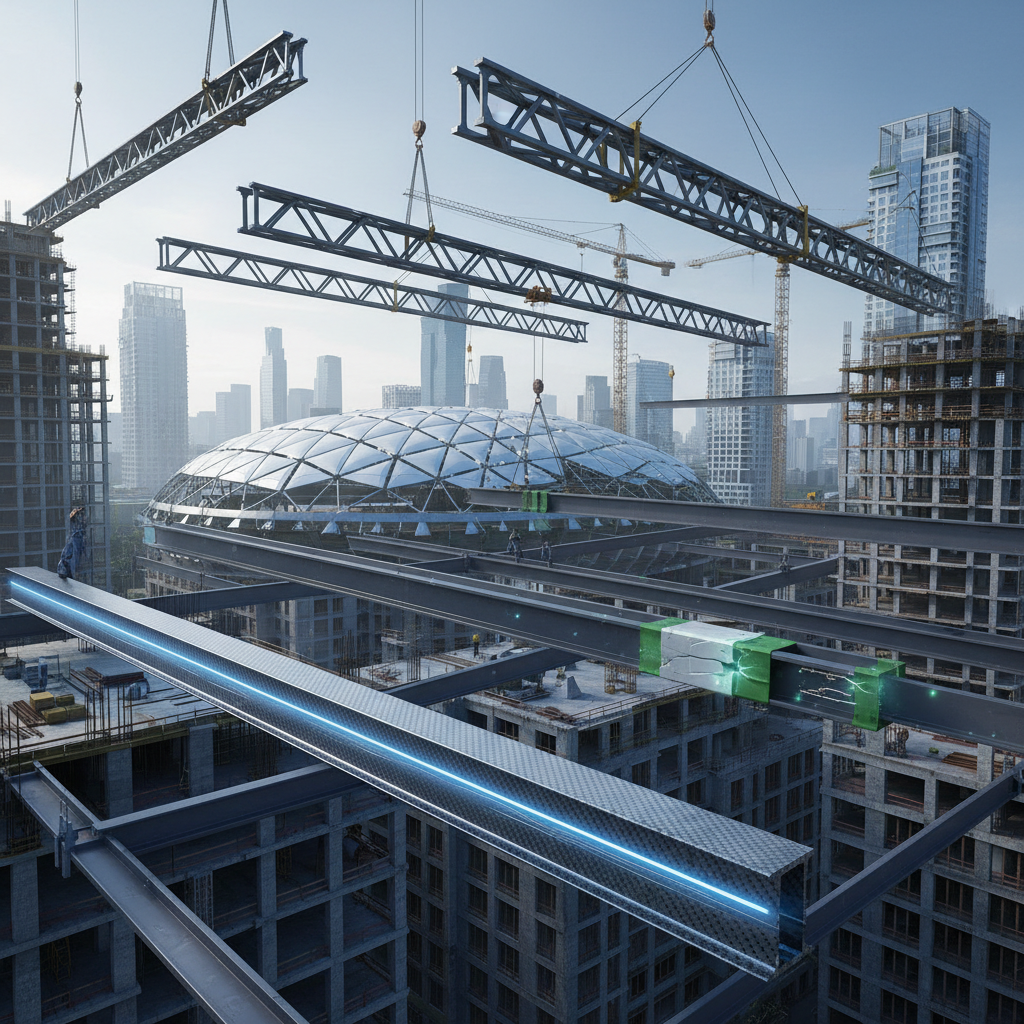

The evolution of steel beam designs is rapidly transforming the construction industry, with a clear emphasis on enhancing strength and longevity. As engineers and architects seek materials that can withstand the rigors of modern infrastructure, innovative approaches are emerging. These advancements incorporate high-strength steel alloys that not only resist corrosion but also allow for lighter structures without compromising on load-bearing capacity. This paves the way for more efficient construction processes and greater design flexibility, enabling architects to realize their ambitious visions.

Moreover, the integration of smart technologies in steel beam production is changing the way we perceive longevity in construction. By embedding sensors within beams, professionals can monitor structural integrity in real time, identifying potential weaknesses before they escalate into serious issues. This proactive approach ensures that buildings are not only robust at the time of construction but remain durable throughout their lifespan. As we move towards 2025, these revolutionary steel beam designs are set to redefine what it means to build with strength and longevity, creating safer and more sustainable structures for future generations.

The integration of smart materials in steel beam construction is set to revolutionize the industry's approach to quality and durability. By utilizing advanced technologies such as nanotechnology and fiber optics, steel beams can now possess enhanced properties that improve their performance over traditional materials. For instance, innovative steel fiber-reinforced composites are being developed to incorporate real-time health monitoring capabilities, allowing for an early detection of structural failures. This real-time feedback not only extends the lifespan of the beams but also ensures safety and reliability in construction.

Moreover, groundbreaking developments in self-healing concrete, utilizing bacteria that produce calcium carbonate, are pushing the boundaries of material science. This technology aims to enhance the durability of concrete structures, potentially leading to a synergistic effect when combined with smart steel beams. The combination of smart materials and self-healing technologies could yield structures that are not only sustainable but also capable of adapting to their environment, ultimately leading to safer, longer-lasting buildings in the future.

The steel beam industry is witnessing a significant shift toward sustainable practices, driven by the urgent need for eco-friendly construction methods. Innovations in steel beam fabrication are pivotal in reducing the carbon footprint of construction projects. According to a report by the World Steel Association, the global steel industry aims for carbon neutrality by 2050, and advancements in manufacturing processes such as electric arc furnace technology are already contributing to a decrease in CO2 emissions. These furnaces use up to 90% less energy than traditional blast furnaces, showcasing how industrial evolution can lead to environmental benefits.

In addition to energy-efficient production, the incorporation of recyclable materials in steel beam fabrication is gaining traction. A study from the American Institute of Steel Construction (AISC) indicates that steel is one of the most recycled materials globally, with recycling rates exceeding 85%. This commitment to reuse not only conserves natural resources but also aligns with the principles of a circular economy. As the construction sector increasingly demands sustainable solutions, innovations such as high-performance steel coatings and advanced material treatments are enhancing the durability of beams, promising longer-lasting structures with lower maintenance requirements. The synergy of these practices marks a promising trajectory for both the industry and the environment.

Advanced coating technologies have emerged as a critical development in the construction industry to enhance the longevity and performance of steel beams. These coatings are designed to provide a robust barrier against the elements, significantly reducing the risk of corrosion and wear that can occur in harsh environments. By utilizing advanced polymeric materials and nanotechnology, manufacturers can create protective layers that not only resist rust but also improve the overall aesthetic appeal of steel structures.

Moreover, innovative techniques such as galvanization, powder coating, and the application of epoxy resins are gaining traction. Galvanization involves coating steel beams with a layer of zinc, which acts sacrificially to protect the underlying metal. On the other hand, powder coating offers a durable finish that is resistant to chipping and scratching, providing both protection and a color selection for design flexibility. These advancements not only extend the lifespan of steel beams but also contribute to sustainable practices by reducing the need for frequent replacements and minimizing maintenance costs over time. As these coating technologies continue to evolve, they will play a pivotal role in the engineering and construction sectors, ensuring that steel beams meet the demands of modern infrastructure.

| Innovation | Description | Material Used | Durability Rating | Corrosion Resistance (Years) |

|---|---|---|---|---|

| Zinc-Rich Coating | A protective layer providing superior corrosion protection. | Zinc | 9/10 | 20 |

| Polyurethane Coating | Flexible coating offering excellent weather resistance. | Polyurethane | 8/10 | 15 |

| Epoxy Coatings | Highly effective against harsh environments and chemical exposure. | Epoxy Resin | 9/10 | 25 |

| Aluminum Coating | Provides a lightweight and corrosion-resistant alternative. | Aluminum | 7/10 | 30 |

| Thermal Spraying | Application of melted materials to form a protective layer. | Various metals | 8/10 | 20 |

| Self-Healing Coating | Innovative coating that repairs itself from damage. | Smart Polymers | 10/10 | 25+ |

| Ceramic Coating | Provides heat and chemical resistance, enhancing lifespan. | Ceramics | 9/10 | 30 |

| Nano-Coating Technology | Extremely thin, yet strong protection against wear and tear. | Nanomaterials | 9/10 | 15 |

| Hybrid Coatings | Combines different materials to enhance performance. | Various composites | 8/10 | 20 |

| Conductive Coatings | Used for electrostatic dissipation and corrosion protection. | Conductive Polymers | 7/10 | 10 |

Integrating smart sensors into steel beams represents a significant advancement in the construction industry, paving the way for real-time monitoring of structural integrity. These sensors can detect various stress factors, including vibrations, temperature changes, and even potential structural failures. By providing continuous data, engineers can make informed decisions about maintenance and repair, significantly enhancing safety and longevity.

Tips: When considering the installation of smart sensors, ensure they are positioned strategically in areas most susceptible to stress. Regularly update the software that processes the sensor data to take full advantage of improvements in technology and analytics.

Implementing this innovative technology not only improves the quality of steel beams but also contributes to sustainable construction practices. By monitoring structural health in real-time, unnecessary repairs can be minimized, ultimately reducing waste and resource consumption. This proactive approach not only maximizes durability but also ensures that maintenance efforts are focused where they are truly needed.

Tips: Collaborate with experienced engineers to choose the right type of sensors based on the specific demands of your project. Establish a routine for reviewing the data collected to enhance predictive maintenance strategies.