In the ever-evolving landscape of construction and design, Tube Steel stands out for its versatility and strength. Renowned industry expert John Smith comments, "Tube Steel is pivotal for modern architectural innovation." His insights highlight the crucial role that Tube Steel plays in adding both resilience and aesthetic value to various projects.

As we head towards 2026, the demand for sustainable and efficient materials like Tube Steel is more pressing than ever. Structural integrity and design flexibility are key. Architects seek materials that not only perform well but also inspire creativity. Tube Steel meets these needs but isn't without its challenges. Fabrication methods can affect its ecological footprint, raising questions about sustainability practices.

The market is filled with options but understanding which Tube Steel product excels can be daunting. Innovations continuously reshape our approach, yet there remains room for improvement. Buyers must navigate both cost-effectiveness and quality. An informed decision could hinge on understanding these dynamics better. Balancing modern demands with traditional strengths will be crucial for Tube Steel's future.

The construction industry is witnessing a transformation with innovative tube steel materials. These advancements are setting new standards in design and structural integrity. A recent report from Global Steel Innovations indicates a growing adoption of high-strength, lightweight tube steel. This material is not only easier to work with but also offers superior durability compared to traditional options.

Some experts note a concerning trend: while innovation is on the rise, not all professionals are keeping pace. In areas lacking expertise, the integration of new materials can lead to issues. For example, improper welding techniques can compromise the strength of tube steel structures. Insights from the American Institute of Steel Construction highlight the need for better training and understanding among workers.

Cost is also a critical factor in this shift. Innovative tube steel products may have a higher initial investment. However, they often lead to long-term savings due to lower maintenance needs and enhanced energy efficiency. Understanding the balance between upfront costs and future benefits is essential for the industry's progress. As innovations continue to emerge, the emphasis should be on education and skill development to maximize these advantages.

| Product Type | Application | Material Grade | Sustainability Rating | Design Flexibility |

|---|---|---|---|---|

| Square Tube | Structural Framework | S235 | Excellent | High |

| Rectangular Tube | Handrails & Guardrails | S355 | Good | Medium |

| Round Tube | Pipes for Transport | C45 | Excellent | High |

| Special Shaped Tube | Custom Applications | Alloy Steel | Fair | Very High |

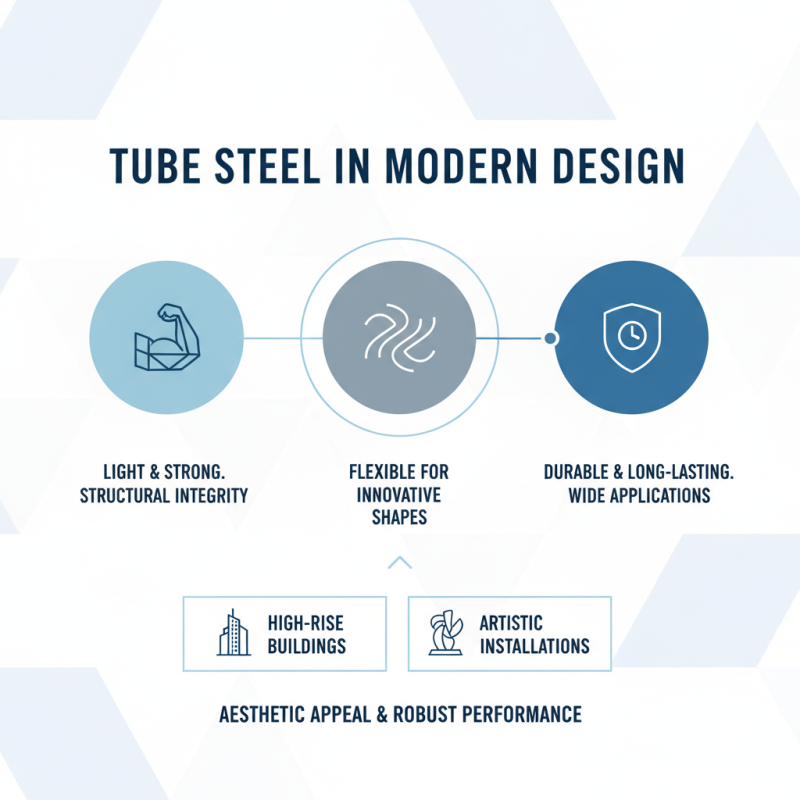

Tube steel has become a popular choice in modern design projects for several key reasons. Its unique properties contribute to both aesthetic appeal and structural integrity. Light yet strong, tube steel provides designers with the flexibility to create innovative shapes and forms. The material's durability ensures longevity, making it suitable for a range of applications, from high-rise buildings to artistically inspired installations.

In modern construction, tube steel can also reduce material waste. This can lead to both cost savings and a lower environmental impact. However, not all projects utilize tube steel to its fullest potential. Some designers overlook the aesthetic variations, like painted surfaces and different finishes, which can improve both functionality and visual impact. If one chooses to ignore these aspects, the design may lack flair.

Another challenge is the welding and joining processes. These can introduce potential points of failure if not executed properly. Proper techniques and skilled labor are crucial to ensure the reliability of the final structure. Each project can pose unique challenges, requiring careful planning and execution. In an ever-evolving design landscape, reflecting on these aspects is essential for success.

The construction industry continually evolves, with tube steel products at the forefront of innovation. These products are essential for structural integrity and design flexibility. Top manufacturers focus on advanced techniques to enhance performance and sustainability. They aim to balance durability with aesthetic appeal, pushing the boundaries of what materials can achieve.

A noteworthy trend is the growing use of lightweight tube steel in modern design. This allows for larger spans and more open spaces in buildings. Yet, challenges remain in ensuring the strength and fatigue resistance of these materials. Manufacturers must invest in research and development to address these issues. It's vital to consider local sourcing to minimize carbon footprints, which can be overlooked amid the rush for innovation.

Another aspect is customization. Tailored tube steel products can meet specific project needs. However, this can lead to longer lead times and higher costs. Balancing customization with efficiency is a constant struggle for manufacturers. They must also anticipate future market demands while maintaining quality standards. The path to innovation is odyssey-like, filled with both successes and areas for reflection.

In recent years, tube steel has emerged as a prominent choice in construction. Its strength makes it ideal for structural applications. Successful cases have shown its capability to create innovative designs while maintaining safety. For instance, tube steel frames in high-rise buildings have transformed skylines. These structures not only withstand harsh conditions but also enable architects to explore unique shapes.

One fascinating project involved using tube steel in a public park structure. The design featured a wave-like canopy, offering shade and visual interest. The flexibility of tube steel allowed for intricate curves. However, challenges arose. Ensuring structural integrity while achieving aesthetic goals was complex. Engineers faced debates over material thickness and connection designs.

Another example is the use of tube steel in bridges. Its lightweight yet strong nature reduces the load on foundations. One project highlighted how tube steel components streamlined installation processes. Yet, miscalculations in design still led to delays. These cases reinforce that while tube steel offers incredible potential, careful planning is essential. Each project teaches valuable lessons that can guide future innovations.

As the construction industry moves forward, tube steel products are becoming integral for sustainable design solutions. Recent reports indicate a growing demand for lightweight yet strong materials. By 2026, tube steel usage in construction could increase by over 30%. This trend highlights the innovation in design and functionality.

Sustainability is a key focus. Tube steel allows for more efficient use of materials, reducing waste. Modern techniques like cold-formed and hot-rolled methods enhance strength while minimizing resources. However, there are challenges. The recycling process for steel is not always efficient. Moreover, construction regulations sometimes lag behind new material capabilities.

Data from industry studies suggests that architects and builders prioritize eco-friendly materials. Over 70% aim to reduce carbon footprints. Despite this, many still rely on conventional practices. The potential for tube steel in energy-efficient buildings is significant. But, it requires a shift in mindset across the industry. Embracing innovative materials is essential for future success.