In the rapidly evolving field of coated coil manufacturing, innovation is paramount. Experts like Dr. Emily Zhang emphasize, "The future of coated coil lies in sustainability and efficiency." Her words resonate as the industry adapts to emerging trends.

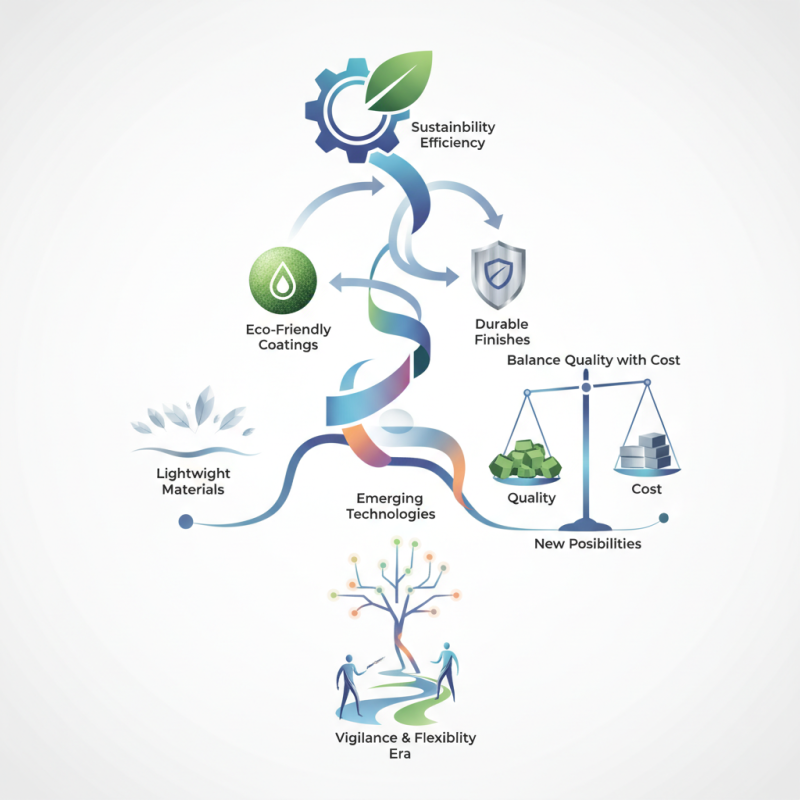

Manufacturers are increasingly focusing on eco-friendly coatings and durable finishes. The demand for lightweight materials is reshaping production methods. However, challenges persist. Many companies struggle to balance quality with cost. This ongoing battle requires introspection and a commitment to improvement.

The landscape of coated coil is more competitive than ever. Emerging technologies offer exciting possibilities. Yet, finding the right balance is crucial. As the industry progresses, stakeholders must remain vigilant and flexible to thrive. This is just the beginning of a transformative era for coated coil.

The coating technology for coated coils is evolving rapidly. Recent industry reports highlight significant leaps in durability and performance. Innovative coatings now offer improved resistance to weathering and corrosion. This ensures longer lifespans for coated materials. According to a study by MarketsandMarkets, the global coated coil market is expected to reach USD 30 billion by 2026.

One exciting trend is the rise of eco-friendly coatings. These products reduce environmental impact while maintaining high quality. The push for sustainability is forcing many manufacturers to rethink their coating processes. While this shift is positive, it presents challenges in maintaining product performance. Balancing eco-friendliness and functionality is tough.

Tips: When selecting coated coils, consider the application environment. Look for higher resistance to UV light and moisture. Test samples whenever possible, as real-world performance can differ.

Another notable advancement involves smart coatings. These coatings can change color or show wear patterns. Such innovations enable better maintenance and monitoring of material conditions. However, the cost of these technologies can be a barrier for smaller manufacturers. They must evaluate whether the benefits outweigh the initial investments.

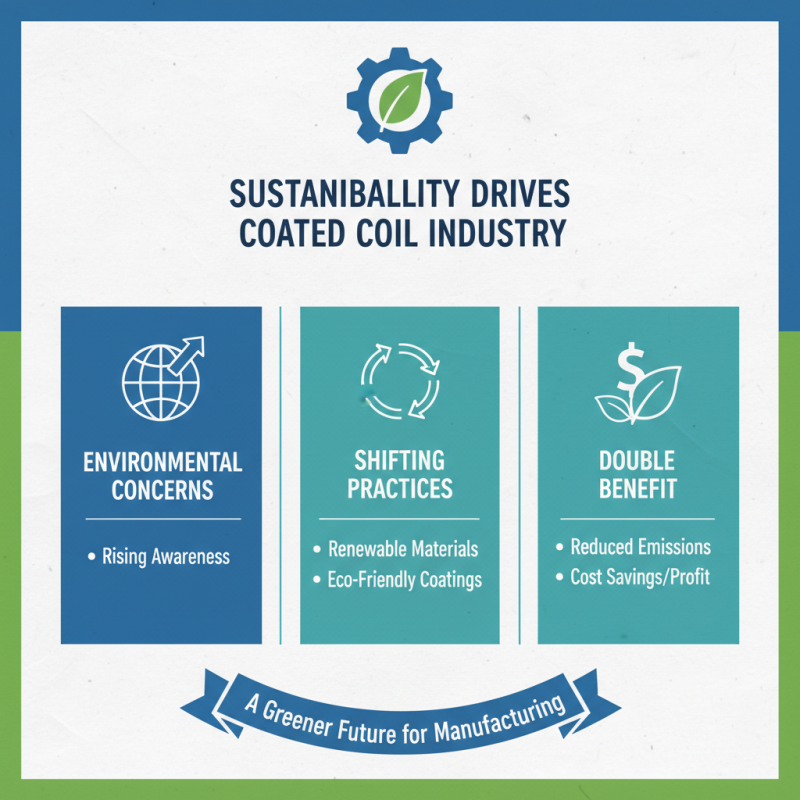

The coated coil industry is increasingly influenced by sustainability trends. As environmental concerns rise, many manufacturers are shifting their practices. Renewable materials are gaining popularity. Companies are seeking eco-friendly coatings that reduce harmful emissions. This helps both the planet and their bottom line.

Investing in energy-efficient processes is another critical trend. Many are exploring ways to reduce energy consumption during production. This not only cuts costs but also lowers carbon footprints. Sustainable sourcing of raw materials is essential too. The industry is slowly realizing the importance of transparency in supply chains.

Tips for businesses: Start small but think big. Implement eco-friendly practices gradually. Consider recycling existing materials before discarding them. Collaboration with suppliers on sustainability goals can bring innovative solutions. Remember, moving towards sustainability is a journey, not a destination. Reflection on current practices can lead to meaningful change.

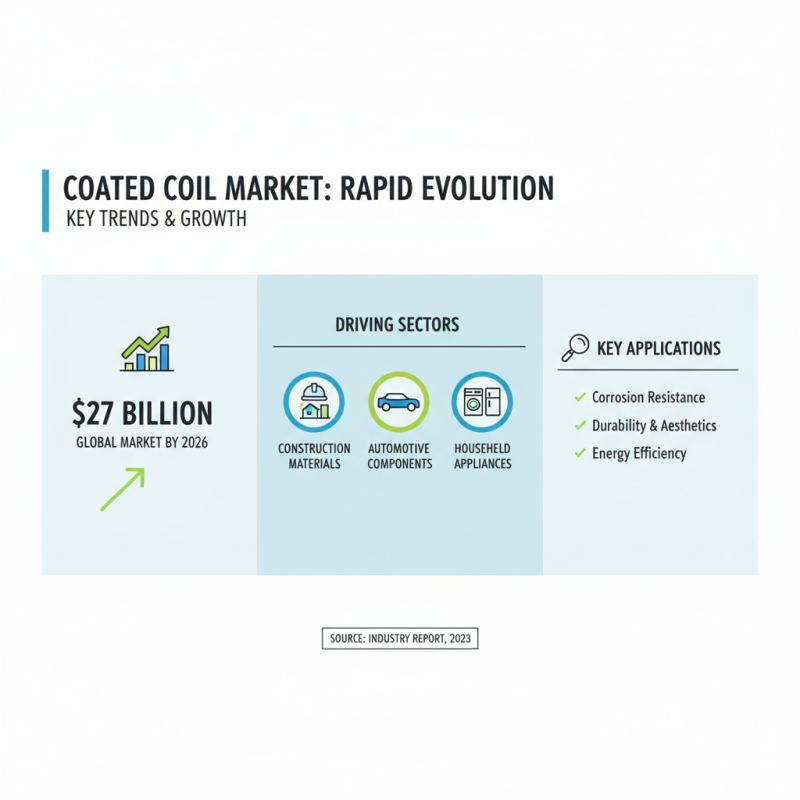

The coated coil market is evolving rapidly, with significant applications across various sectors. According to a recent industry report, the global coated coil market is expected to reach $27 billion by 2026. This growth signals a rising interest in construction materials, automotive components, and household appliances.

In the construction sector, coated coils are preferred for their durability and aesthetic appeal. Buildings now utilize these materials for roofing, siding, and facades. A data trend from industry analysts indicates that coated coils improve energy efficiency by up to 30%. However, there is a concern about the environmental impact of coatings used in these processes. Sustainable practices are needed to address potential health risks linked to certain chemicals.

The automotive industry is also embracing coated coils. With lightweight and corrosion-resistant properties, these materials can enhance vehicle performance. It is estimated that around 15% of a vehicle's weight can be reduced through the use of advanced coated coils. However, manufacturers are still grappling with the challenges of balancing cost and quality. The demand for innovative coatings that can withstand extreme weather conditions continues to rise. This highlights a gap in research and development, calling for new solutions that address performance without compromising safety.

The coated coil industry is evolving rapidly. Several market trends shape its future. One of the key trends is the increasing demand for sustainable materials. Many manufacturers are shifting towards eco-friendly coatings. According to a recent industry report, the market for sustainable coated coils is projected to grow by 15% annually through 2026. This shift indicates a strong consumer preference for environmentally responsible products.

Another significant trend is technological advancement in production processes. Innovations like advanced coating techniques and automation improve efficiency and quality. These changes enable manufacturers to meet rising demands while minimizing waste. As researchers note, data shows a 20% decline in production costs thanks to new technologies, which benefit both producers and consumers.

Tips: Focus on sourcing from suppliers who prioritize sustainability. Keeping an eye on emerging technologies can lead to better product choices. Customer feedback is essential for improving offerings. Embrace the journey of innovation, but remain aware of the challenges. Outdated practices can hinder progress, so regular reassessment is crucial.

The coated coil industry faces several challenges in its manufacturing processes. One notable issue is material waste. A report by MarketsandMarkets reveals that about 28% of materials used in coil production become scrap. This inefficiency not only increases costs but also impacts sustainability efforts. Manufacturers must find innovative ways to minimize waste while maintaining quality.

Quality control is another hurdle. Inconsistent coatings can lead to defects and customer dissatisfaction. A recent study shows that approximately 15% of coated coils fail quality tests. Implementing stricter quality checks can ensure a higher standard. However, this often means additional expenses and longer lead times for production. Balancing speed and quality remains a constant struggle.

Tip: Streamline your production processes to reduce waste. Look into advanced technologies that enhance precision.

On the opportunity side, automation plays a crucial role. Automation can improve efficiency and reduce labor costs. The International Data Corporation predicts that automation could increase productivity by up to 30% in the next five years. However, workforce training for new technologies is essential. Without proper investment in skills development, companies may struggle to leverage these advancements.

Tip: Invest in workforce training programs to maximize the benefits of new technologies. A skilled workforce can drive innovation.