As we look toward the future of construction, the role of Steel Piles becomes increasingly significant. These foundational elements provide the strength and stability necessary for various structures. In 2026, advancements in design and materials will likely enhance their effectiveness even further.

Steel Piles are essential for projects in demanding environments. They excel in rocky or unstable soil. Their resilience under heavy loads cannot be overstated. However, choosing the right type of Steel Piles remains a complex decision. Different projects may require different specifications.

Amid the advancements, challenges also exist. Manufacturers must ensure consistent quality. Environmental considerations are more important than ever. It’s vital for engineers to balance performance with sustainability. As we navigate these challenges, reflection on past practices may lead to better future outcomes.

Steel piles play a crucial role in foundation construction, providing strength and stability to various structures. These long, cylindrical metal rods are driven deep into the ground, reaching bedrock or stable soil. According to the Foundation Engineering Handbook, about 50% of buildings in urban areas utilize steel piles for their foundations. Their load-bearing capacity is significant, allowing structures to withstand heavy loads and vibrations.

When considering steel piles, it's essential to understand their types. There are several options, including H-piles and pipe piles. H-piles are often favored for their high strength-to-weight ratio. They can manage high loads while minimizing material costs. Pipe piles, with their hollow structure, offer excellent resistance to buckling, making them suitable for challenging soil conditions.

Tips: Regular inspections are vital. Check for corrosion or structural damage. Understanding soil conditions before installation is equally important. It ensures the right pile type is chosen. Be aware that not all projects require the same pile specifications; this can lead to overspending or structural failures. Always analyze project needs carefully.

In modern foundation projects, steel piles play a crucial role. They provide stability and strength to structures. Various types of steel piles are commonly used today. Each type has its unique qualities and applications.

Driven piles are one of the most popular options. They are hammered into the ground, ensuring deep penetration. This method can lead to potential noise and disruption, however. Another option is drilled shafts. These offer flexibility in varying soil conditions. Workers create a borehole and then fill it with concrete. While this method is precise, it can be time-consuming.

Hollow piles are also gaining traction. They are lightweight and easy to transport. Their design allows for effective load transfer. However, this can lead to questions about durability. Each pile type involves trade-offs. Choosing the right one should focus on site conditions and project needs. Balancing cost, strength, and practicality is essential.

| Type of Steel Pile | Typical Use | Material Strength (MPa) | Length Range (m) | Installation Method |

|---|---|---|---|---|

| H-Piles | Heavy Load Applications | 250-350 | 6-30 | Driving |

| Pipe Piles | Marine and Offshore Structures | 300-400 | 6-20 | Bored or Driven |

| Sheet Piles | Earth Retention and Waterfront | 280-350 | 5-12 | Driving |

| Concrete-Encased Steel Piles | High Strength Requirements | 300-450 | 8-25 | Bored or Driven |

| Mini Piles | Limited Access Areas | 200-300 | 5-15 | Drilled and Grouted |

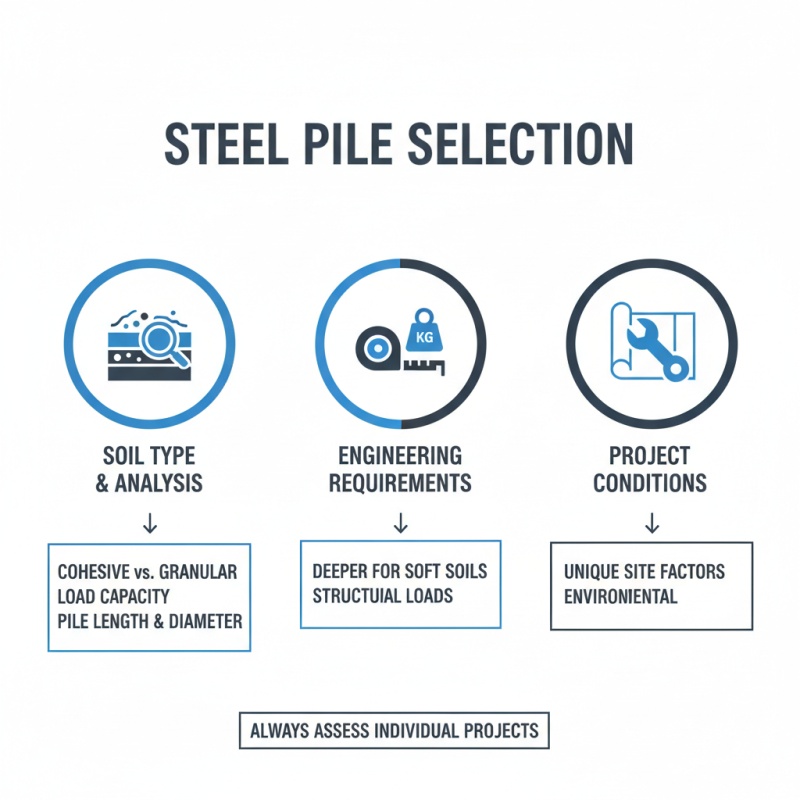

When selecting steel piles for foundation construction, multiple factors come into play. The type of soil is crucial. Cohesive soils behave differently compared to granular ones. A soil analysis can reveal load-bearing capacities. This helps determine the required length and diameter of the piles. You might need deeper piles in softer soils. Always remember that every project has unique conditions.

Another important consideration is corrosion resistance. Steel piles can be vulnerable to rust, particularly in moist conditions. Protective coatings can extend their lifespan. However, the effectiveness of these coatings may vary. Some may chip or wear off over time. Regular inspections are necessary to assess the condition of the piles.

Budget constraints also influence choices. Steel piles can be expensive, but they have longevity. Evaluating cost versus lifespan becomes essential. Sometimes, cheaper alternatives may lead to larger expenses in maintenance. Reviewing past project losses can guide future decisions. Each option has pros and cons, requiring careful thought.

The steel pile technology is evolving rapidly. Innovations in materials and design are crucial for future construction. Current trends show that high-strength, corrosion-resistant alloys are becoming popular. According to a recent industry report, up to 30% of construction projects now prioritize sustainability. This demand drives research into green steel technologies.

Smart monitoring solutions are also gaining traction.

Sensors embedded within steel piles can provide real-time data. This new technology helps predict structural integrity, potentially extending the life of the foundation. Some studies suggest that regular monitoring can reduce maintenance costs by 25%. However, the integration of such technology still poses challenges. Implementation costs may deter some smaller companies.

Another area of innovation is the development of pre-fabricated piles. These structures can be manufactured off-site, reducing on-site labor. Some reports indicate that pre-fabrication can improve efficiency by 40%. Yet, standardization remains an issue. Variances in ground conditions require customization, which complicates mass production. This creates a paradox: seeking efficiency while managing unique site challenges.

When it comes to foundation construction, choosing the right type of pile is crucial. Steel piles have gained popularity due to their strength and durability. A study by the American Institute of Steel Construction shows that steel piles can bear much heavier loads compared to concrete or timber alternatives. For instance, steel piles can support loads exceeding 50 tons each, which is often necessary for large structures.

In contrast, concrete piles can crack under heavy loads. This limitation can lead to significant structural issues over time. Moreover, timber piles, while cost-effective, are susceptible to decay and pests. Reports indicate that structures relying on timber piles often face higher maintenance costs after just a few years of service. Therefore, assessing long-term resilience is essential for any construction project.

Tips: Consider soil conditions before selecting the pile type. Steel piles perform well in varying soil types, but research local soil profiles first. Additionally, assess the load demands of the structure to ensure optimal pile selection. Be prepared for potential delays if unexpected soil conditions arise during installation.