In the world of construction and manufacturing, the choice of materials can significantly impact the success and durability of projects. Tube Steel, with its versatile applications and robust properties, has emerged as a leading option for various industries in 2023. According to a recent market analysis by the Steel Construction Institute, the demand for Tube Steel has surged by over 15% this year, driven by its favorable strength-to-weight ratio and ease of fabrication. This increase underscores the material's growing importance in both structural and non-structural applications.

Industry expert Dr. Emily Carter, a noted authority in materials engineering, highlighted the significance of selecting high-quality Tube Steel for project efficiency, stating, "Using the right type of Tube Steel not only enhances the structural integrity of a project but also optimizes cost-effectiveness and construction timelines." Her insight reflects the critical role that Tube Steel plays in modern engineering applications. As we explore the best options available, understanding the variety of Tube Steel types and their specific advantages will be paramount for engineers and builders aiming to achieve excellence in their projects.

When considering tube steel for your next project in 2023, it's crucial to understand the various types available to make an informed decision. Tube steel primarily comes in different shapes, including round, square, and rectangular. Each shape has its unique strengths and applications. For instance, round tubes are often favored for their structural integrity and ability to withstand stress in many industrial applications, while square and rectangular tubes provide excellent rigidity and are commonly used in construction and support frameworks.

In addition to shape, the material composition of tube steel varies, with options such as mild steel, stainless steel, and aluminum. Mild steel is known for its affordability and ease of fabrication, making it a popular choice for general construction. Stainless steel offers superior corrosion resistance, ideal for architectural and marine applications. Aluminum tube steel, on the other hand, is valued for its lightweight properties, making it a preferred choice for projects where reducing weight is essential without sacrificing strength. Understanding these different tube steel options will help you select the most suitable type for your specific needs.

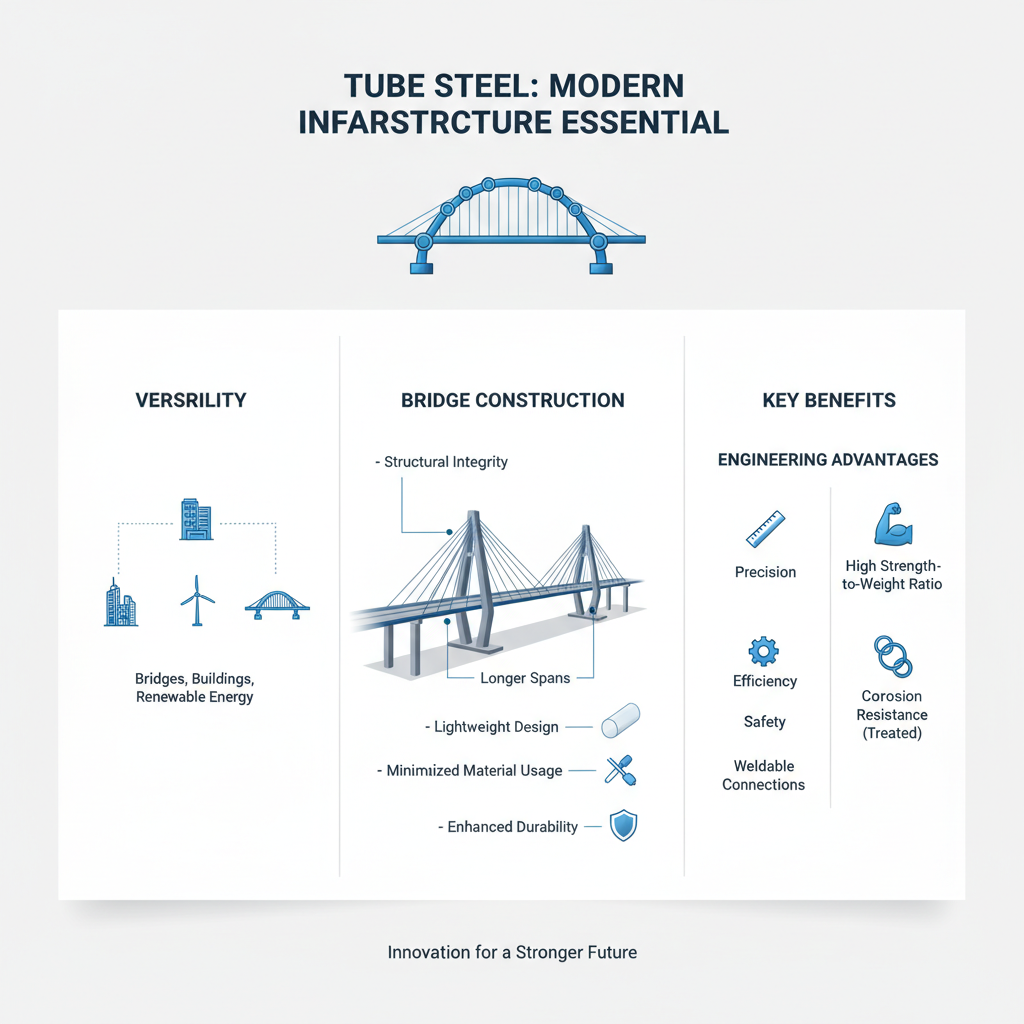

Tube steel has emerged as a preferred material in construction and engineering projects due to its remarkable strength, durability, and versatility. One of the primary benefits of using tube steel is its ability to withstand significant structural loads, making it ideal for beams, columns, and frames in both residential and commercial buildings. Additionally, tube steel offers a lightweight alternative compared to traditional steel options, which can reduce transportation costs and simplify handling on-site.

When choosing tube steel for your project, consider the specific requirements of your design. For instance, if you are working on a structure that requires high resistance to bending and torsion, opting for rectangular or square tubes may be advantageous. On the other hand, round tubes are excellent for applications that require high strength and aesthetic appeal.

Tip: Always verify the specifications of your tube steel against the structural requirements of your project to ensure safety and compliance. Additionally, don't overlook the importance of corrosion resistance—selecting galvanized or coated tube steel can significantly prolong the life of your construction. Remember, investing time in material selection can lead to long-term benefits for your project.

When selecting tube steel for your project, several key considerations should guide your decision. First, assess the intended application of the tube steel. Different projects may require varying strength, durability, and flexibility levels. For instance, structural applications may benefit from high-strength steel with specific yield and tensile properties, while decorative projects might prioritize aesthetic factors over structural integrity.

Another important factor to consider is the size and shape of the tube steel. Common profiles include square, rectangular, or round tubes, each offering distinct advantages. The choice of profile can affect things such as load distribution and ease of fabrication. Additionally, don’t overlook the importance of thickness; a thicker wall provides added strength but can also increase weight and cost. Finally, consider the environment where the tube steel will be used; corrosion resistance might be crucial for outdoor projects, leading you to choose galvanized or stainless steel options.

Tube steel has become an essential element in modern infrastructure, demonstrating versatility across various application areas. One of the most notable uses is in the construction of bridges. The structural integrity and lightweight nature of tube steel enable engineers to design longer spans and minimize the use of materials without compromising safety. Additionally, the welded connections found in tube steel constructions facilitate quicker assembly and enhance durability, making it ideal for both pedestrian and vehicular bridges.

Another key area where tube steel excels is in the development of commercial buildings. Architects favor tube steel for its aesthetic appeal and robust performance under load. It's often used in frameworks, allowing for expansive open spaces within the interior design. With the rise of sustainable construction practices, tube steel's recyclability further boosts its appeal, aligning with the growing emphasis on environmentally friendly materials. Moreover, tube steel's resistance to corrosion makes it suitable for various indoor and outdoor applications, ensuring longevity and reduced maintenance costs.

When sourcing tube steel for your next project in 2023, understanding the best practices in logistics and supplier relations is essential. Given the pressures of inflation and unpredictable supply chains, operators must adopt a proactive mindset. This involves establishing robust relationships with suppliers and diversifying sourcing options to mitigate risks. Implementing controls throughout the procurement process can enhance resilience, allowing companies in construction and beyond to navigate the complexities of today's market more effectively.

Sustainability is increasingly a priority in procurement strategies, particularly in the construction sector. Companies are now focusing on green public procurement, aiming to not only meet project needs but also minimize their environmental impact. By prioritizing suppliers committed to reducing carbon emissions and adopting sustainable practices, firms can contribute to broader ecological goals. This strategic approach not only fulfills contractual obligations but also helps decarbonize operations, positioning companies as leaders in building a more environmentally responsible future.