In the construction and manufacturing industries, the versatility of rolled bar has made it an indispensable material for various applications. As industry expert Dr. Emily Thompson, a leading figure in structural engineering, aptly puts it, “Rolled bar not only improves the strength of our structures but also enhances design flexibility.” This insight reflects the significance of rolled bar in creating resilient frameworks while allowing for innovative architectural solutions.

The unique properties of rolled bar, including its adaptability and high strength-to-weight ratio, have positioned it as a favored choice among engineers and manufacturers. From reinforcing concrete to being utilized in the fabrication of heavy machinery, its applications are vast and varied. A detailed examination of the best uses for rolled bar reveals how this essential component drives efficiency and reliability across multiple sectors.

As we explore the top ten uses for rolled bar in construction and manufacturing, it becomes clear that understanding its characteristics and advantages can lead to more effective design and construction practices, ensuring that industry professionals are well-equipped to meet the demands of modern projects.

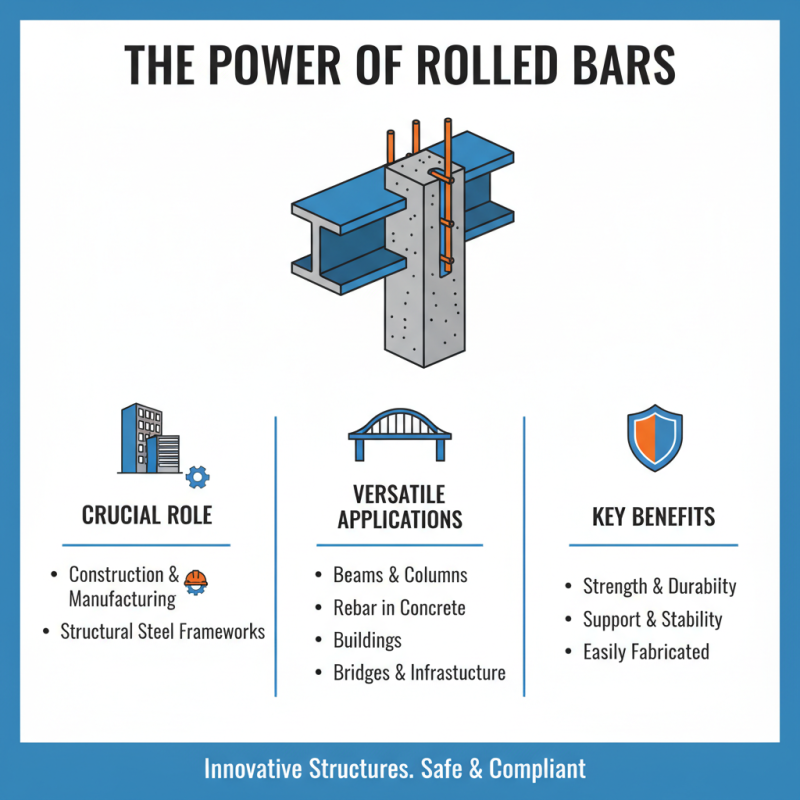

Rolled bars play a crucial role in the construction and manufacturing industries, particularly in structural steel frameworks. These versatile materials are widely utilized for a variety of applications, ranging from beams and columns to reinforcement bars in concrete structures. The strength and durability of rolled bars make them an excellent choice for providing support and stability in buildings, bridges, and other infrastructure projects. Their ability to be easily fabricated into various shapes allows architects and engineers to design innovative structures while ensuring safety and compliance with building codes.

Tips: When selecting rolled bar for your project, consider the load requirements and environmental conditions it will face. Different grades of steel offer varying levels of tensile strength and corrosion resistance, which can significantly impact the longevity of your structure. Always consult with a structural engineer to determine the best specifications for your specific applications.

In addition to traditional uses in construction, rolled bars are increasingly being used in manufacturing processes, such as creating frames for machinery or support systems for industrial operations. The adaptability of rolled bars allows for customization, making them suitable for both large-scale projects and smaller construction tasks. Incorporating rolled bars into your designs can lead to increased efficiency and reduced costs while maintaining structural integrity.

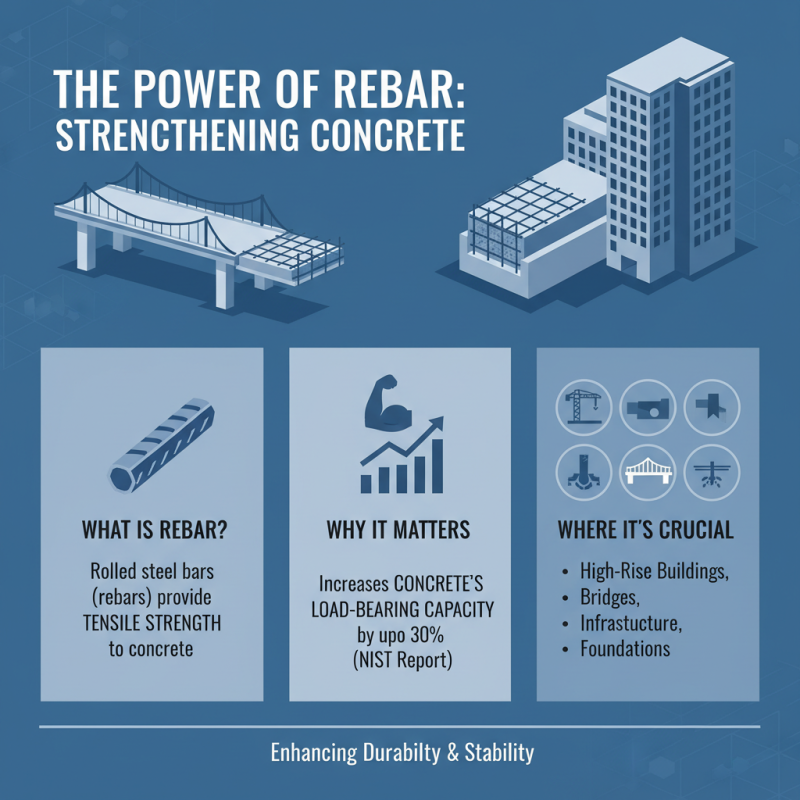

Rolled bar, commonly known as rebar, plays a crucial role in reinforced concrete construction due to its ability to provide tensile strength, enhancing the overall stability and durability of concrete structures. According to a report from the National Institute of Standards and Technology, the integration of appropriate rebar types and sizes can increase the load-bearing capacity of concrete by up to 30%. This characteristic is vital in constructing high-rise buildings, bridges, and various infrastructure projects that endure significant loads and environmental stressors.

When utilizing rolled bar in reinforced concrete, it is essential to adhere to recommended practices to maximize structural integrity. For instance, ensuring proper spacing and coverage of rebar can prevent corrosion and enhance longevity. Additionally, employing varying diameters of rolled bars based on structural requirements can significantly influence the performance of concrete structures.

Tips: Always refer to the American Concrete Institute guidelines for selecting the appropriate rebar size and grade for specific construction needs. Regular inspections of rebar before pouring concrete can identify defects early, ensuring a robust and reliable foundation. Additionally, consider using epoxy-coated rebar in areas with high exposure to moisture to further safeguard against corrosion.

In the machinery and equipment manufacturing sectors, rolled bar is an essential material due to its versatility and strength. Rolled bars are produced through hot or cold rolling processes that enhance their mechanical properties, making them suitable for a variety of applications. According to a report by the American Iron and Steel Institute, the manufacturing sector consumes around 50% of all rolled steel products, highlighting the importance of materials like rolled bar in achieving structural integrity and durability in machinery.

One significant application of rolled bar is in the production of frames and structural components of heavy machinery. The high tensile strength of rolled bar allows manufacturers to create equipment that can withstand heavy loads and extreme conditions, resulting in enhanced safety and performance. Reports indicate that machinery made with rolled bar components can last up to 30% longer than those using inferior materials, providing manufacturers with more reliable performance and reducing maintenance costs over time.

Moreover, rolled bars are increasingly utilized in the production of precision components such as shafts, axles, and fittings. High-precision machining techniques, often combined with rolled bar, allow for the fabrication of custom-engineered solutions that meet specific operational needs. The Bureau of Labor Statistics notes that the machine manufacturing industry is expected to grow by 7% over the next decade, with rolled bar as a key material in meeting this demand due to its adaptability to various manufacturing processes. This growth further underlines the role of rolled bar in driving advancements in machinery design and production efficiency.

Rolled bars are essential components in the construction and manufacturing industries, particularly due to their significant advantages in fabrication processes. The structural integrity provided by rolled bars allows for robust construction solutions, tailored to meet varying load requirements. According to a report by the American Institute of Steel Construction, using rolled bars can lead to a remarkable decrease in construction time, enhancing productivity by up to 20%. Their uniformity in shape and size ensures ease of handling and installation, making them invaluable in projects that demand efficiency and precision.

Moreover, rolled bars offer superior machinability and weldability compared to other steel forms. The American Welding Society highlights that the clean edges of rolled bars reduce the risk of defects in welded seams, promoting stronger and more durable connections. With a variety of grades available, fabricators can select the ideal rolled bar that meets specific project criteria, ensuring both performance and reliability. The adaptability of rolled bars to different fabrication techniques—such as bending, cutting, and drilling—further emphasizes their role in fostering innovation in both construction and manufacturing sectors. Studies indicate that the use of rolled bars in fabrication processes not only enhances the aesthetic flexibility of structures but also contributes to overall project sustainability.

| Use Case | Industry | Advantages | Specifications |

|---|---|---|---|

| Reinforcement bars | Construction | High tensile strength, improves structural integrity | Diameter: 12mm to 32mm |

| Machinery components | Manufacturing | Durability, easy to machine | Length: Customizable |

| Structural beams | Construction | Load-bearing capacity, cost-effective | Width: 5cm to 10cm |

| Ties and bracing | Construction | Stability against lateral forces | Thickness: 10mm |

| Shipping racks | Logistics | Lightweight yet strong | Height: Customizable |

| Cable supports | Telecommunications | Corrosion resistance, tensile strength | Diameter: 8mm to 20mm |

| Furniture frames | Furniture manufacturing | Stylish design, strength | Thickness: Up to 5mm |

| Transport structures | Transport | Robustness, reduced weight | Length: Up to 6m |

| Framework of buildings | Construction | Versatile applications, easy to assemble | Profile: Round, square, or rectangular |

| Safety barriers | Construction | Protective, easy installation | Height: 1m |

The environmental impact and sustainability of using rolled bar in construction and manufacturing are increasingly significant as industries strive to adopt greener practices. Rolled bars, primarily made of steel or metal alloys, have a lower footprint when compared to less durable materials. Their longevity and resilience reduce the need for frequent replacements, thereby minimizing waste and resource consumption. Furthermore, many manufacturers are now focusing on utilizing recycled materials in their production processes, which not only conserves natural resources but also reduces energy consumption associated with mining and processing raw materials.

To maximize the sustainability of rolled bar usage, industry professionals can implement several important tips. First, opting for suppliers that prioritize eco-friendly practices, such as sourcing recycled materials, can enhance the overall sustainability of a project. Secondly, conducting a life cycle assessment for rolled bar products can help stakeholders understand the environmental impacts associated with sourcing, manufacturing, and disposal. This knowledge can inform better decision-making and promote responsible material choices. Lastly, regular maintenance and proper care of rolled bar structures can extend their lifespan and efficiency, thereby contributing to a more sustainable industrial practice.