When it comes to construction materials, the choice often leans towards durability and reliability. The use of Galvanized Sheet is one such choice that stands out in the industry. Leading expert in metal engineering, Dr. Emily Hart, emphasizes, “Galvanized Sheets provide unmatched corrosion resistance, making them ideal for structural applications.”

These sheets are coated with zinc, which prevents rust and enhances longevity. They are lightweight yet strong, making them ideal for various building projects like roofing and siding. However, it’s essential to consider the environment where these sheets will be used. Factors like humidity and exposure to harsh weather can affect performance.

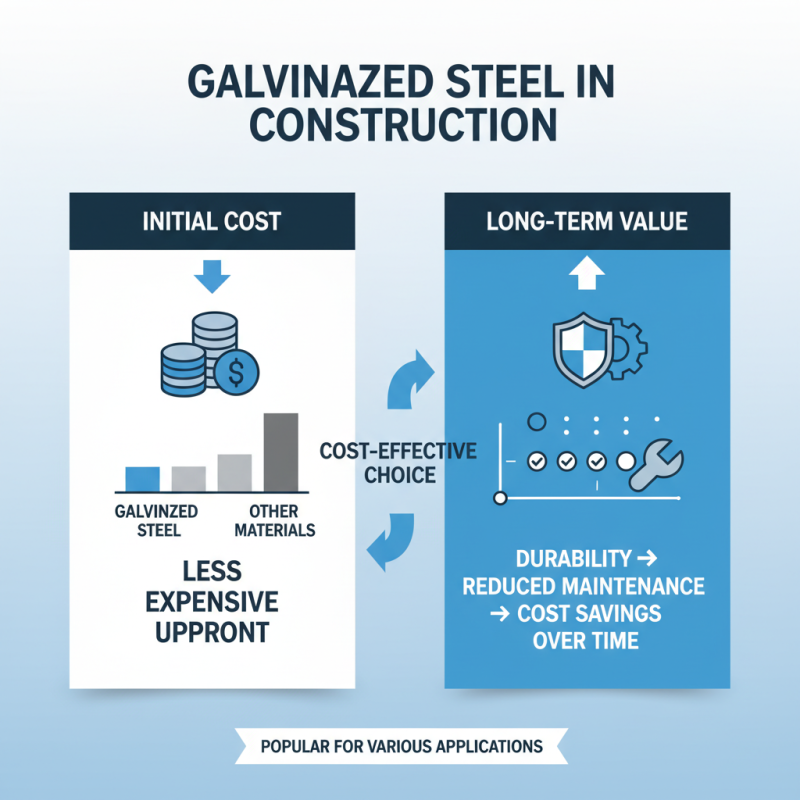

Despite their benefits, some may overlook Galvanized Sheets due to cost concerns. While they might seem pricier upfront, their long-lasting nature often outweighs initial expenses. Reflecting on choices is vital. Are we prioritizing short-term savings over long-term value? The decision to choose Galvanized Sheet could lead to greater peace of mind in your construction endeavors.

Corrosion resistance is crucial in construction materials. In environments exposed to moisture, steel can corrode swiftly. The National Association of Corrosion Engineers (NACE) reports that corrosion costs the U.S. economy about $276 billion annually. This staggering amount highlights the need for durable materials. Galvanized sheets offer a practical solution due to their zinc coating. This coating protects the metal underneath, extending its lifespan.

When considering construction projects, the longevity of materials matters. Galvanized sheet steel can last up to 50 years in certain environments. This lifespan surpasses that of regular steel significantly. Moisture and chemicals can still affect it, but the initial corrosion resistance is strong. A study by the International Zinc Association indicates that galvanizing can reduce maintenance costs by up to 35%. This is critical, especially for structures exposed to harsh weather.

However, not all conditions are ideal for galvanized materials. In highly acidic or alkaline environments, failure can occur. Over time, the zinc layer may degrade. It's essential to evaluate local conditions. Using galvanized sheets is not always a foolproof choice. Understanding the specific environmental factors at play can lead to better decisions in material selection.

When considering building materials, galvanized sheet stands out. This metal is coated with zinc to resist corrosion. According to a study by the American Galvanizers Association, galvanized steel can last up to 50 years in harsh environments. This longevity makes it ideal for construction projects that demand durability.

Using galvanized sheets enhances structural integrity significantly. They can withstand heavy loads and resist weathering changes. The National Institute of Standards and Technology reported that structures made with galvanized materials showed improved life spans. For instance, highway bridges using galvanized steel demonstrate reduced maintenance costs over time.

However, it’s essential to acknowledge some concerns. The initial costs can be higher than non-galvanized options. Some may question if the upfront investment is worth it. Over time, the lower maintenance and replacement need often balance this. Regular inspection is crucial to ensure optimal performance. Investing in knowledge about material choices can lead to better decisions.

Galvanized sheets are a popular choice in construction projects. Their cost-effectiveness makes them appealing for various applications. Compared to other materials, galvanized sheets are less expensive upfront. They offer durability, which can reduce expenses over time due to lower maintenance needs.

The protective zinc coating on galvanized sheets enhances their lifespan. They resist rust and corrosion much better than non-coated metals. This means fewer repairs and replacements. Over time, the initial savings on galvanized sheets can translate into significant financial benefits. However, it is essential to evaluate the specific project requirements before deciding. Not all jobs need galvanized sheets.

Sometimes, projects may benefit from alternative materials. While galvanized sheets perform well in many situations, they may not be the best option for all environments. Local weather conditions can impact their effectiveness. It’s wise to consider the long-term impacts on your budget. Understanding both the pros and cons will help make the right choice.

When utilizing galvanized steel in construction, adherence to industry standards is crucial. The American National Standards Institute (ANSI) sets guidelines for the coating thickness of galvanized steel. Typically, a minimum of 1.2 ounces per square foot is recommended for optimal protection. This ensures resistance to corrosion, extending the material’s lifespan.

Compliance with the ASTM A123/A123M standard is also vital. This standard governs the hot-dip galvanizing process, ensuring that the steel meets specific quality benchmarks. For instance, the steel must be free of surface defects and have adequate coating thickness. Such regulations contribute to structural integrity and safety in buildings and infrastructure.

Moreover, while galvanized steel is favored for its durability, some construction professionals express concerns. There are instances where improper coating leads to early corrosion. This points to the importance of using reliable suppliers who adhere strictly to these standards. Consequently, careful selection and quality inspection are necessary to prevent reflective outcomes. Engaging in regular quality audits can help in maintaining the necessary thresholds for construction projects.

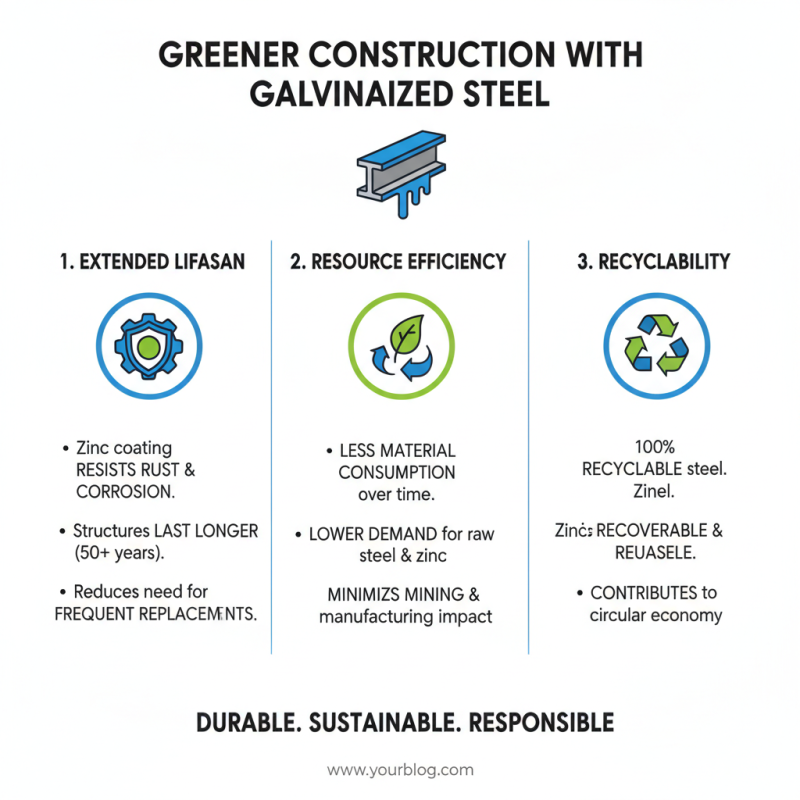

Galvanized sheets offer significant benefits in construction, particularly regarding their environmental impact. These sheets are made from steel coated with a layer of zinc. This process helps prevent rust and corrosion. As a result, structures built with galvanized steel have a longer lifespan. This durability means fewer materials are required over time, lessening resource depletion.

Moreover, galvanized sheets are recyclable. When construction projects are completed, materials are often discarded. However, galvanized steel can be repurposed easily. This reduces waste in landfills and supports a circular economy. Some might argue recycling processes can have their shortcomings, yet the overall impact remains positive.

Despite these advantages, there are concerns. The production of galvanized sheets does involve energy use and emissions. Waste management in manufacturing still needs improvement. Exploring better methods for sourcing zinc could also enhance sustainability. It's essential to consider both the benefits and areas needing attention. Galvanized sheets reflect a step toward more environmentally-friendly practices in construction. But as with any material, a careful approach is necessary.