In the world of construction, selecting the right materials is crucial for the success of any project. One of the essential components often used is the Angle Bar, a versatile piece that provides structural support and stability. According to industry expert John Smith, a leading structural engineer, "The choice of Angle Bar can significantly affect not only the strength of the structure but also its overall longevity." This highlights the importance of understanding various factors when selecting the appropriate Angle Bar for specific construction needs.

When it comes to choosing an Angle Bar, considerations such as the material grade, dimensions, and load-bearing requirements come into play. Each project presents unique challenges, and a well-informed decision can ensure that the finished structure is both safe and durable. By taking the time to evaluate these factors, builders can optimize their designs and meet the necessary safety standards. Ultimately, a careful selection process will lead to not only a successful construction project but also a long-lasting investment.

When selecting angle bars for construction projects, understanding the different types available is crucial to ensure structural integrity and efficiency. Angle bars, typically made from steel, aluminum, or other metals, are categorized by their dimensions, materials, and finishes. Common types include

equal angle bars, where both legs are of the same length, and

unequal angle bars, featuring differing leg lengths.

According to a 2021 report by the Global Steel Construction Market, the demand for angle bars is projected to grow by 5.2% annually, driven by increased infrastructure investments worldwide.

Material choice also plays a significant role in performance characteristics. For example, steel angle bars are favored for their high tensile strength, making them suitable for heavy-duty applications, while aluminum angle bars are lighter and resist corrosion, ideal for marine environments. The American Institute of Steel Construction indicates that properly selected angle bars can significantly reduce the overall weight of a structure without compromising safety.

Furthermore, surface finish options, such as galvanizing or painting, are essential in enhancing durability, especially in challenging environmental conditions. Understanding these distinctions allows construction professionals to make informed decisions that align with project requirements and standards.

When selecting the right angle bar for your construction projects, it is crucial to consider multiple key factors to ensure structural integrity and longevity. Firstly, the material of the angle bar plays a significant role. Common materials include steel, aluminum, and stainless steel, each offering different properties such as strength, weight, and resistance to corrosion. For projects exposed to harsh environmental conditions, opting for a rust-resistant material like stainless steel is advisable.

Additionally, the dimensions and thickness of the angle bar should align with the requirements of your project. A thicker angle bar provides more strength and support, making it suitable for heavy loads. Conversely, a smaller angle bar might suffice for lighter applications. It is essential to perform a load calculation to determine the appropriate thickness needed to ensure safety and compliance with building codes.

**Tips:** Always consult with structural engineers or experienced professionals when in doubt about the specifications. Additionally, consider the ease of handling and installation; lighter materials can reduce labor costs and installation time, enhancing project efficiency. Finally, ensure you have a reliable supplier who can provide accurate measurements and material certifications for your angle bars.

| Parameter | Description | Recommended Value |

|---|---|---|

| Material | Common materials include steel, aluminum, and stainless steel. | Mild Steel |

| Angle Size | Size of the angle bar, typically represented in dimensions, e.g., 50mm x 50mm. | 50mm x 50mm |

| Thickness | Thickness of the angle, crucial for weight-bearing applications. | 5mm |

| Load Capacity | Maximum load the angle bar can support without failure. | 2000 kg |

| Finish | Surface treatment to prevent corrosion, such as galvanizing or painting. | Galvanized |

| Standards | Compliance with industry standards for safety and quality. | ASTM A36 |

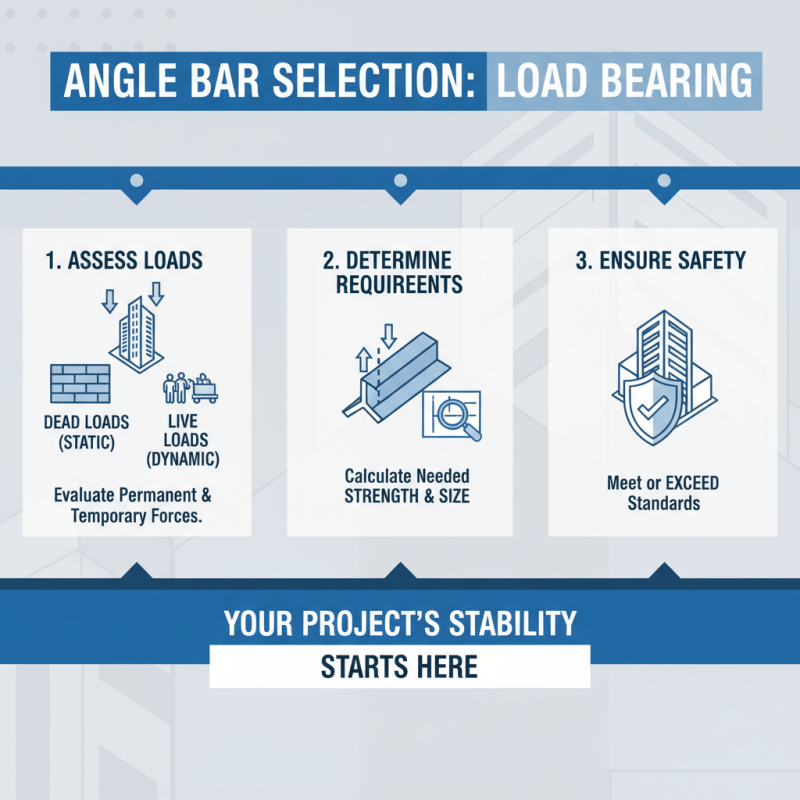

When selecting the appropriate angle bar for your construction project, assessing load-bearing requirements is essential. Angle bars serve various structural purposes, and understanding the load they must support will directly influence the type and size of the bar you choose. Begin by evaluating the expected loads, including both dead loads (permanent/static weight of the structure) and live loads (temporary/dynamic forces). This assessment will allow you to determine the necessary strength and dimensions of the angle bar, ensuring it meets or exceeds structural safety standards.

Furthermore, consider the environmental factors that may affect the angle bar’s performance. Factors such as wind loads, seismic activity, and temperature fluctuations can all impact the material’s integrity and load-bearing capacity. It’s vital to account for these elements when calculating the required specifications for your angle bar. By conducting a thorough analysis of load-bearing requirements and external conditions, you can select a suitable angle bar that not only supports your project's needs but also enhances overall safety and durability.

When evaluating material options for angle bars in construction projects, the choice between steel and aluminum is crucial. Steel angle bars are renowned for their strength and durability, making them ideal for structural applications. According to the American Institute of Steel Construction, steel's tensile strength can reach up to 250 ksi, offering considerable resistance to bending and deformation under load. However, while steel can withstand significant weight and stress, it is also susceptible to corrosion, necessitating protective coatings in humid or saline environments.

On the other hand, aluminum angle bars provide a lightweight alternative with excellent resistance to corrosion. An analysis published by the Aluminum Association highlights that aluminum is nearly one-third the weight of steel, allowing for easier handling and installation. Although aluminum's strength is lower than that of steel, advancements in aluminum alloy technology have improved its performance in structural applications. In fact, some high-strength aluminum alloys can achieve tensile strengths comparable to lower-grade steel, making them suitable for various construction projects where weight savings are essential.

Tips: When choosing between steel and aluminum angle bars, consider the environment in which they will be used. If the project is in a coastal area or prone to moisture, aluminum may be the better choice due to its corrosion resistance. Additionally, weigh the overall project requirements, including load-bearing capacities and longevity, to ensure that the selected material aligns with your specific needs.

When selecting angle bars for construction projects, understanding the right size and dimensions is crucial for structural integrity and functionality. Angle bars, typically measured by their leg lengths and thickness, should be chosen based on the specific requirements of the project. For instance, larger dimensions may be necessary for heavy-load applications, while smaller sizes might suffice for lighter structures. Evaluating the project's load-bearing requirements will guide the selection process, ensuring that the angle bars can withstand the intended loads without compromising safety.

Additionally, considering the material of the angle bars is equally important, as different materials can significantly affect weight and overall performance. Steel angle bars are popular due to their high strength-to-weight ratio, while aluminum options might be preferred for their corrosion resistance in certain environments. It's essential to calculate the width, height, and thickness of the angle bars in relation to the overall design and functionality of the construction project. By taking these factors into account, construction professionals can ensure they select the most appropriate size and dimensions for angle bars, contributing to a successful and durable build.