When embarking on a construction project, the choice of materials is crucial to its success, longevity, and structural integrity. One material that has gained significant popularity in recent years is Corrugated Steel. Known for its unique ribbed design, Corrugated Steel offers a combination of strength, durability, and versatility, making it suitable for a wide range of applications, from roofing to structural supports. As you navigate the complexities of material selection, understanding the various types and specifications of Corrugated Steel is essential to meet the specific needs of your construction project.

Selecting the right Corrugated Steel involves considering multiple factors, including thickness, finish, and galvanization. Each of these characteristics can greatly influence the performance of the material under different environmental conditions. Whether you are constructing a residential building, an industrial warehouse, or an agricultural structure, making an informed decision about the type of Corrugated Steel you use can determine the overall quality and lifespan of your construction. This introduction aims to provide insights into the key considerations when choosing Corrugated Steel, ensuring that your project stands the test of time while meeting both aesthetic and functional requirements.

Corrugated steel has become a popular choice in construction due to its durability and versatility. Understanding its basics is crucial before making a selection for your project. Corrugated steel sheets consist of a series of ridges and valleys, which enhance their strength while keeping them lightweight. This material can be used for roofs, walls, and even structural components depending on the thickness and form you choose. Familiarizing yourself with different types of corrugated steel and their applications can ensure you're making an informed decision.

**Tips**: When selecting corrugated steel, consider the thickness required for your project. Thicker sheets typically offer greater strength and resistance to harsh weather conditions. Additionally, evaluate the type of galvanization, as it influences the material’s durability against corrosion and rusting. Before installation, inspect for any defects to ensure optimal performance.

Another essential factor is understanding the gauge of the corrugated steel. Lower gauge numbers indicate thicker sheets, which might be necessary for high-load areas. Additionally, be mindful of the profile design, as some shapes may provide better aerodynamics or water runoff, depending on your building's architectural needs. Choosing the right profile can enhance both the aesthetic and functional qualities of your project.

| Steel Type | Gauge | Coating Type | Applications | Durability (Years) |

|---|---|---|---|---|

| Galvanized Steel | 16 | Zinc | Roofing, Siding | 50+ |

| Aluminum-Coated Steel | 18 | Aluminized | Agricultural Buildings | 40+ |

| Pre-painted Steel | 20 | Polyester | Commercial & Residential Roofing | 30+ |

| Cold-formed Steel | 14 | Zinc | Structural Applications | 20+ |

| Stainless Steel | 22 | N/A | Marine & Harsh Environments | 50+ |

When evaluating different types of corrugated steel materials for your construction projects, it's essential to consider various factors that can influence performance and suitability. Various profiles, such as sinusoidal and trapezoidal, offer distinct advantages depending on the application.

Sinusoidal corrugated steel, for instance, is known for its aesthetic appeal and is commonly used for roofing, while trapezoidal profiles provide exceptional strength and are often favored for wall cladding in commercial structures.

Tips: Before making a selection, assess the load-bearing requirements of your project. Different corrugated steel profiles have varying strengths and may be more or less suitable for heavy-duty applications. Consulting with a structural engineer can help identify the most appropriate choices based on weight and environmental factors.

Additionally, consider the thickness of the steel sheets. Thicker materials typically offer better durability and resistance to wear and corrosion, which can be critical in harsh climates. Evaluate the environmental conditions your structure will face, and choose a gauge that ensures longevity while maintaining budget constraints. Understanding these key aspects will help you make an informed decision that aligns with your construction needs.

When selecting the right corrugated steel for construction projects, assessing the structural requirements is paramount. The American Iron and Steel Institute (AISI) notes that corrugated steel offers superior strength-to-weight ratios, which is essential for a variety of applications, including roofing and siding. A study conducted by the Steel Construction Institute indicates that proper assessment of load-bearing capabilities can enhance durability and reduce maintenance costs by up to 40%. Understanding the loads that the structure will be subjected to—such as live loads, dead loads, and environmental loads—will help guide the selection of appropriate gauge and corrugation profile.

Moreover, the environmental conditions of the project site must be evaluated. Structural requirements differ significantly in areas prone to heavy winds, snow, or seismic activity. The National Steel Construction Association (NSCA) emphasizes the importance of choosing corrugated steel that meets local building codes and standards for safety and performance. For instance, utilizing steel that complies with ASTM A572 can provide enhanced strength for structures in high-risk zones. By thoroughly assessing these factors, engineers can ensure that the chosen corrugated steel will meet the demands of the project while providing reliability and longevity.

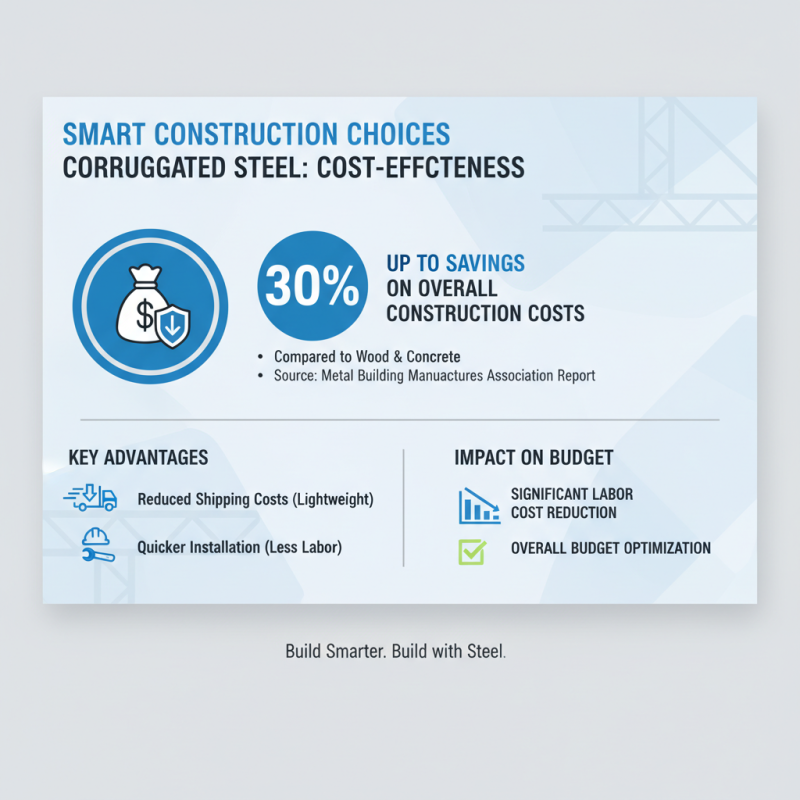

When selecting corrugated steel for construction projects, cost-effectiveness is a paramount consideration. According to a report by the Metal Building Manufacturers Association, metal buildings and components can save up to 30% on overall construction costs when compared to traditional materials such as wood and concrete. This is mainly due to the lightweight nature of corrugated steel, which reduces shipping costs and facilitates quicker installation. Therefore, reducing labor costs can significantly impact the overall budget.

Additionally, the longevity and durability of corrugated steel contribute to its cost-effectiveness. The American Iron and Steel Institute highlights that steel structures can last well over 50 years with minimal maintenance, which reduces long-term expenditures. In comparison to other materials that may require frequent repairs or replacements, investing in high-quality corrugated steel can yield substantial savings over the lifespan of a building. Furthermore, fluctuations in raw material costs should also be considered when budgeting. Recent industry analyses suggest that while the price of steel may vary, its overall value proposition remains strong due to its recyclability and sustainability, offering financial incentives for eco-conscious projects.

Ultimately, understanding both the initial investment and long-term financial implications is critical in choosing the right corrugated steel for construction endeavors. Emphasizing efficient sourcing and evaluating lifecycle costs will ensure that stakeholders make informed decisions that align with their budgetary constraints and project goals.

When selecting suppliers for corrugated steel, it is essential to evaluate their adherence to quality standards. A recent industry report by the American Institute of Steel Construction indicates that about 20% of construction failures are attributed to inadequate material quality. Therefore, partnering with manufacturers who comply with recognized standards, such as ASTM or EN, can significantly mitigate risks associated with poor material performance. Before finalizing a supplier, it’s crucial to verify their certification status, manufacturing processes, and whether their products have undergone rigorous testing for strength, durability, and corrosion resistance.

In addition to quality assurance, ensure that the suppliers offer transparency regarding their sourcing of raw materials. As per a report by the Global Recycling Foundation, around 90% of steel production today is derived from recycled sources, which demonstrates the industry's commitment to sustainability. Collaborating with suppliers who practice sustainable sourcing can enhance your project's environmental profile and align with the growing consumer preference for green building practices. Thus, choose suppliers attentive to both quality and sustainability to ensure the longevity and performance of your construction projects.