When embarking on a construction project, one of the critical decisions that project managers must face is the selection of suitable materials, particularly when it comes to retaining structures. A vital option in this arena is the Steel Sheet Pile, renowned for its strength, durability, and efficiency in various applications such as waterfront construction and soil retention. As industry expert John Smith, a noted structural engineer, once said, "Choosing the right Steel Sheet Pile is not just about the material; it's about understanding the specific needs of each project."

With a diverse range of Steel Sheet Piling products available, it is essential to consider several factors that influence the decision-making process. The choice of material properties, thickness, and design characteristics all play a significant role in ensuring the stability and longevity of the structure. Additionally, factors such as environmental conditions and the anticipated loads must be meticulously evaluated.

Ultimately, the right Steel Sheet Pile can lead to significant cost savings, increased safety, and enhanced project performance. As we delve deeper into the nuances of selecting Steel Sheet Piles, we will explore key considerations and best practices that can guide you in making the most informed choice for your construction endeavors.

When selecting steel sheet piles for your construction project, several critical factors must be considered to ensure optimal performance and cost-efficiency. First, soil conditions play a significant role. According to a report by the American Society of Civil Engineers, nearly 70% of construction failures stem from insufficient understanding of soil properties. Conducting thorough geotechnical investigations helps identify soil types and their respective load-bearing capacities, enabling the selection of sheet piles that can withstand lateral loads effectively.

Another crucial aspect is the corrosion resistance of the steel sheet piles. Corrosion can significantly shorten the lifespan of the piles, leading to expensive repairs or replacements. A study published in the Journal of Construction Engineering and Management indicated that utilizing protective coatings can enhance durability, extending the service life by up to 50%. Therefore, assessing environmental conditions and choosing suitable coatings based on the project’s location is vital for ensuring longevity and reducing overall maintenance costs.

Tips: Always consult with structural engineers to evaluate load requirements and potential soil issues before making a decision. Additionally, consider future site conditions, as changes in water levels and potential flooding can influence the effectiveness of your chosen sheet piles. Regular monitoring and maintenance plans can also help in addressing any emerging corrosion issues early.

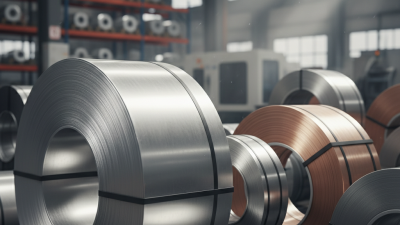

When selecting the appropriate steel sheet pile for a construction project, it's essential to understand the various types available and their specific applications. Steel sheet piles are predominantly categorized into three types: Z-shaped, U-shaped, and flat sheet piles. Z-shaped piles, recognized for their interlocking capability, are particularly suited for retaining walls and deep foundation applications, providing significant resistance to lateral pressures. According to a report by the American Institute of Steel Construction (AISC), projects utilizing Z-shaped piles can enhance stability in both soil and water conditions, making them ideal for waterfront construction.

U-shaped sheet piles, on the other hand, offer versatile applications, particularly in the formation of temporary structures or as barriers against water ingress. Their open design allows for easy installation and provides effective drainage, which is crucial for sites prone to flooding. A study conducted by the Steel Construction Institute highlights that U-shaped piles are frequently utilized in excavation support systems due to their ability to effectively manage earth movements while minimizing disruption to surrounding areas.

Flat sheet piles are typically employed in applications requiring a lightweight solution, such as temporary cofferdams or vibration-sensitive zones. The ease of handling these piles, coupled with their cost-effectiveness, adds to their appeal in small to medium-sized projects. According to data from the International Design and Engineering Association, the growth in the use of flat sheet piles has increased by approximately 15% annually, reflecting their rising popularity in construction where site constraints dictate the need for flexible and less intrusive solutions.

When selecting steel sheet piles for a construction project, one of the foremost considerations is the load-bearing capacity. This involves assessing the anticipated loads that the piles will support, which includes vertical loads from structures above as well as lateral earth pressures. Engineers often utilize various analytical methods, such as limit state design and finite element analysis, to evaluate how different pile designs will respond under these loads. Understanding the soil conditions, including the type of soil and groundwater levels, is critical, as these factors greatly influence the pile's performance and ultimate stability.

Equally important is the structural integrity of the steel sheet pile itself. This includes examining the material properties, thickness, and design profile to ensure it can withstand environmental conditions such as corrosion, hydraulic pressure, and seismic forces. The design must account for potential buckling and lateral stability, ensuring that the steel sheet piles maintain their form and function throughout the project's lifespan. By meticulously analyzing these aspects, engineers can ensure that the chosen steel sheet piles will provide the necessary support and durability required for successful construction outcomes.

This chart illustrates the load-bearing capacity (in kN) of various types of steel sheet piles, highlighting their structural integrity for construction projects.

When budgeting for steel sheet piling in your construction project, it's essential to take various cost factors into account. The initial purchase price of the steel sheets is critical but doesn’t encompass the entire financial picture. Additional costs include transportation, installation, and any necessary treatments or coatings to enhance durability. Evaluate the overall life-cycle cost of the materials to better understand the long-term financial commitment involved.

Tips for effective budgeting include conducting a detailed cost analysis early in the planning phase. Consult with suppliers to obtain quotes and clarify what is included in those quotes. Additionally, consider how local market conditions may influence prices. Unexpected expenses can arise during the construction process, so it’s wise to include a contingency fund in your budget to cover unforeseen challenges.

Another noteworthy aspect of budgeting is the assessment of project timelines. Delays can result in higher costs due to increased labor or extended equipment rentals. Incorporating realistic timeframes can contribute to a more accurate budget and help you avoid financial strain later on. Planning meticulously encompasses not only the direct costs but also the ancillary expenses that can dramatically affect your project's bottom line.

When selecting steel sheet piles for construction projects, compliance with industry standards and regulations is crucial to ensure the safety and integrity of the structure. The American Society for Testing and Materials (ASTM) provides specifications that detail material properties and performance requirements for steel sheet piles. ASTM A-driven standards ensure that the chosen products can withstand the environmental and load conditions they will be subjected to. For instance, data from the American Institute of Steel Construction indicates that a well-chosen sheet pile system can lead to significant cost savings in terms of material usage and maintenance in the long term.

Moreover, engineers must also consider the local regulations that govern construction practices. Many jurisdictions require adherence to specific environmental regulations aimed at minimizing ecological impact during installation. According to reports from the Environmental Protection Agency, projects that comply with these regulations often face smoother approval processes, leading to reduced delays and associated costs. By understanding both national standards and local regulations, project managers can select steel sheet piles that not only meet structural requirements but also align with environmental considerations and legal compliance, ultimately contributing to the project's success.