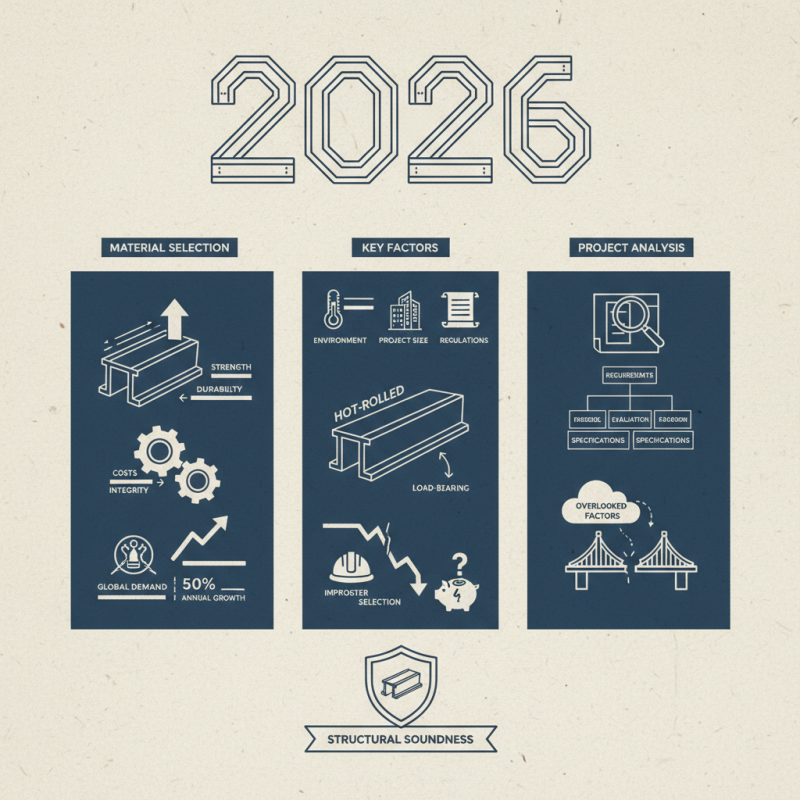

Channel steel is a crucial material in construction. Selecting the right type can significantly impact structural integrity and costs. According to industry reports, the global demand for channel steel is projected to grow by 5% annually until 2026. This rise highlights the importance of making informed choices in material selection.

When considering channel steel, factors such as material grade and dimensions should be addressed. For instance, hot-rolled channel steel is often preferred for its strength and durability in load-bearing applications. Data shows that improper material selection can lead to increased project costs and safety concerns. This emphasizes the need for careful evaluation.

Analyzing your construction requirements is essential. Local regulations, environmental conditions, and project size all play roles in channel steel selection. Construction experts suggest that many projects fail to assess these factors comprehensively. This oversight can be detrimental, leading to structural challenges later on. Thus, understanding channel steel’s specifications and implications is vital for any construction endeavor.

Channel steel, a vital component in construction, comes in various types and specifications. Commonly used for beams and frames, it offers strength and versatility. Understanding the types can help you choose the right channel steel for your project. Types often include standard, U-shaped, and I-shaped channel steel. Each has unique properties that suit specific applications. For instance, U-shaped channels are great for structural support, while standard shapes offer better load distribution.

Tips for selecting channel steel: consider the weight capacity required for your construction. Look into factors like environmental conditions and intended use. Structural integrity matters; therefore, it's wise to consult professionals. Some channel steel might not perform well under specific loads. You should reflect on the dimensions necessary for your project. Ensure that your selection aligns with safety standards.

Also, be mindful of cost and availability. Sometimes, the most affordable option may be subpar in quality. Verify material specifications and ask questions if unsure. Sometimes, overlooked details lead to project delays. Balancing cost with quality can be challenging but is essential for a successful outcome.

When selecting channel steel, several critical factors influence the decision. One primary consideration is the load-bearing capacity required for your construction project. Different channel steel sizes and shapes cater to varying loads. According to industry reports, using the correct weight specification can reduce structural failure by up to 30%. Choosing channel steel that aligns with your project’s demands ensures safety and efficiency.

Another factor is the material used. Channel steel is often made from different alloys or steel grades. Each offers unique properties such as corrosion resistance and tensile strength. Some projects may require galvanized steel if they are exposed to moist environments. Reports indicate that galvanized steel can extend the lifespan of constructions by an average of 15 to 20 years.

Cost is also a significant element, yet it should not be the sole determinant. Sometimes cheaper options might lead to future repairs. The initial investment is crucial, but total life cycle cost is more relevant. A thorough evaluation helps prevent overspending on shortcuts that may diminish quality. Consider long-term impacts over short-term gains when making your choice.

| Factor | Description | Recommended Values |

|---|---|---|

| Material Grade | The strength and durability required for the application. | S235, S275, S355 |

| Dimensions | Length, width, and height specifications based on project requirements. | Available from 50mm to 300mm in width |

| Weight | Weight per meter affects the overall load calculations. | 5 kg/m to 20 kg/m |

| Surface Treatment | Protective coatings to enhance corrosion resistance. | Galvanized, painted, or untreated |

| Application | Specific uses in construction, such as beams or frames. | Residential, commercial, industrial applications |

| Compliance Standards | Standards set by local or international specifications. | ASTM, EN, ISO standards |

When selecting channel steel for your construction project, size matters. The dimensions of the channel can greatly affect structural integrity. For instance, a smaller channel may suffice for light framing. But heavier loads require larger, thicker sections. You'll need to consider load capacity, spans, and the overall design of the structure.

Different sizes have their unique properties. Standard channel shapes can vary in height, weight, and flange width. A wider flange may provide better stability. However, it can also add unnecessary weight. It's essential to balance the needs of your project. Choosing the wrong size can lead to complications later. Reassessing your requirements can save time and money.

Be prepared for trial and error. You may find that ideal specifications don’t match what you planned. Testing smaller batches in real conditions can help. Keep a close eye on how your chosen channel performs. Feedback is invaluable. It's a part of the process, and reflection on what worked can guide future projects.

Channel steel plays a vital role in construction projects. It is widely used in building frameworks, bridges, and support structures. According to a report by the Steel Construction Institute, channel steel is known for its strength-to-weight ratio. This makes it a favorable choice for a variety of applications.

In terms of applications, channel steel is ideal for vertical and horizontal supports. Its shape allows for easy integration into different construction elements. The American Institute of Steel Construction states that channel steel can effectively bear heavy loads. This is essential in high-rise buildings and industrial installations. However, improper selection of channel steel dimensions can lead to structural weaknesses.

Moreover, channel steel is often used in renovation projects. It can reinforce old structures without extensive alterations. Observations show that many builders overlook the importance of finish and corrosion treatment. These aspects significantly contribute to durability. It’s crucial to remember that even high-quality steel can fail without proper care. Being aware of the environmental conditions can guide effective choices in channel steel.

When sourcing channel steel, choosing the right provider is crucial. Look for suppliers who specialize in steel products. Their expertise can lead to better quality materials. Also, visit their facilities if possible. Seeing their processes can give you insight into their standards.

Handling channel steel requires care. Always wear gloves to protect your hands. Sharp edges can cause cuts easily. Store the channel steel properly to prevent warping. Use wood or other materials to cushion the steel against hard surfaces. Too much weight on one side can lead to bending, which is a common oversight.

Transporting channel steel can also pose challenges. Ensure that the payload is evenly distributed. An unbalanced load can cause accidents. Think about using straps to secure your materials. This small step can save significant headaches later on. Inspect your steel after transport. Small nicks or scratches might seem minor but can affect overall integrity. Keep these details in mind to ensure a successful project.