In the rapidly evolving industrial landscape, the selection of the right metal coil has become a crucial factor for operational efficiency and product quality. According to a recent report by the International Metal Association, the global metal coil market is projected to reach $150 billion by 2025, driven by the increasing demand across various sectors such as automotive, construction, and manufacturing. As industries strive for higher performance and sustainability, understanding the specific properties and applications of different metal coils is essential for making informed decisions.

Expert insights reinforce the significance of this topic. Dr. Emily R. Thompson, a leading specialist in materials science, emphasizes, “Choosing the correct metal coil is not merely a procurement decision; it directly impacts the integrity and durability of the end product.” This assertion highlights the relationship between metal coil characteristics—such as tensile strength, corrosion resistance, and processing capabilities—and their ultimate impact on industrial applications. With various materials, including aluminum, stainless steel, and copper available, industries must carefully evaluate their specific requirements to ensure optimal performance and longevity.

As we approach 2025, understanding the nuances of metal coil selection will be paramount for businesses aiming to enhance their competitive edge and environmental sustainability. This guide will navigate the essential considerations and provide insights into how to choose the right metal coil for diverse industrial needs.

When selecting the right metal coil for industrial applications, it's crucial to understand the various types available and their specific uses. Common metal coil types include stainless steel, aluminum, and galvanized steel. Stainless steel coils are known for their corrosion resistance and strength, making them ideal for food processing and chemical industries. Aluminum coils, being lightweight and malleable, are often used in transportation and packaging applications. Galvanized steel coils, coated with zinc for rust prevention, are favored in construction and automotive sectors.

Tips: Consider the environment where the metal coil will be utilized. For instance, if the application involves exposure to moisture or corrosive substances, stainless steel may be the best option. Additionally, evaluate the coil's thickness and dimensions based on your project's requirements, as these factors can significantly affect the material's performance.

It's also important to assess the manufacturing process and the mechanical properties of the coils. Different applications may require varying tensile strength and ductility. Understanding these properties will help ensure that you select a metal coil that not only fits your industrial needs but also enhances the efficiency and longevity of your projects. When in doubt, consulting with industry experts or material specialists can provide valuable insights tailored to your specific requirements.

| Metal Coil Type | Thickness (mm) | Width (mm) | Material Composition | Applications |

|---|---|---|---|---|

| Cold Rolled Steel Coil | 0.5 - 3.0 | 600 - 1500 | Carbon Steel | Automotive, Construction |

| Galvanized Steel Coil | 0.3 - 2.5 | 600 - 1250 | Carbon Steel with Zinc Coating | Construction, Appliances |

| Aluminum Coil | 0.2 - 5.0 | 300 - 1500 | Aluminum Alloy | Packaging, Transportation |

| Stainless Steel Coil | 0.5 - 4.0 | 600 - 1500 | 304, 316 Grades | Food Processing, Chemical |

| Copper Coil | 0.5 - 3.0 | 600 - 1200 | Copper Alloy | Electrical, HVAC |

When selecting the right metal coil for industrial applications, several key factors come into play that can significantly impact performance and efficiency. One primary consideration is the material composition of the coil. For instance, stainless steel, aluminum, and carbon steel are commonly used, each offering distinct advantages. According to a report by the Metal Packaging Association, stainless steel is favored for its corrosion resistance and durability, making it ideal for applications in food processing and pharmaceuticals, where hygiene is paramount.

Another critical factor is the gauge and thickness of the metal coil. Thickness impacts not only the strength and weight of the material but also its formability and use in various processes. The American Iron and Steel Institute indicates that metal coils typically range from 0.014 inches to over 0.500 inches in thickness, affecting application suitability. Understanding the required mechanical properties in relation to the intended use—whether for structural applications or intricate fabrication—will guide decisions in choosing the appropriate gauge.

Finally, the intended application and environmental conditions should be evaluated. For example, coils used in outdoor environments require materials that can withstand moisture and other weather elements. A report from the International Stainless Steel Forum highlights how environmental factors can lead to rust and degradation in materials not suited for exterior use. Taking these considerations into account ensures optimal performance and longevity of metal coils in diverse industrial contexts.

When selecting the right metal coil for industrial applications, it is crucial to compare the material properties of different options to ensure optimal performance.

Aluminum coils, for instance, are known for their excellent corrosion resistance and lightweight characteristics, making them ideal for applications in the automotive and aerospace sectors. According to a report by the Aluminum Association, the use of aluminum in automotive manufacturing can improve fuel efficiency by up to 30% compared to traditional steel, providing a compelling argument for its selection in relevant industries.

On the other hand, stainless steel coils are favored for their durability and strength, particularly in applications where hygiene is paramount, such as in food processing and pharmaceuticals. The International Stainless Steel Forum (ISSF) states that stainless steel's resistance to corrosion and staining significantly enhances product longevity and safety.

Moreover, carbon steel coils, while less resistant to corrosion, offer high tensile strength and flexibility, making them cost-effective for construction and heavy machinery applications. The Global Steel Industry report highlights that carbon steel remains a dominant choice for structural applications due to its resilience and lower production costs compared to specialized alloys.

Each metal coil type presents unique advantages and challenges; therefore, understanding these material properties in the context of specific industrial needs is essential for informed decision-making. Choosing the right metal coil not only influences product performance but can also impact manufacturing costs and efficiency.

When selecting the appropriate metal coil for industrial applications, understanding quality standards and certifications is crucial. Industry reports indicate that over 70% of manufacturers prioritize compliance with recognized quality standards when sourcing materials. Certifications such as ISO 9001, which emphasizes a quality management system, ensure that suppliers adhere to rigorous manufacturing and operational processes. According to a recent study by the Manufacturing Institute, companies certified under these standards experience a 15% increase in efficiency and a 20% reduction in defect rates, highlighting the positive impact of quality assurance on production outcomes.

Additionally, specific certifications, such as ASTM and ASME, play an essential role in identifying the suitability of metal coils for specialized applications. These standards define material properties and testing methods, providing assurance that the metal coils can withstand the operational demands of industries like aerospace and automotive. Reports suggest that compliance with these standards aids in minimizing compliance risks and enhancing product safety, a top concern for over 60% of industry stakeholders. As such, thorough assessment of quality certifications not only boosts supply chain reliability but also supports long-term operational excellence in the increasingly competitive industrial landscape.

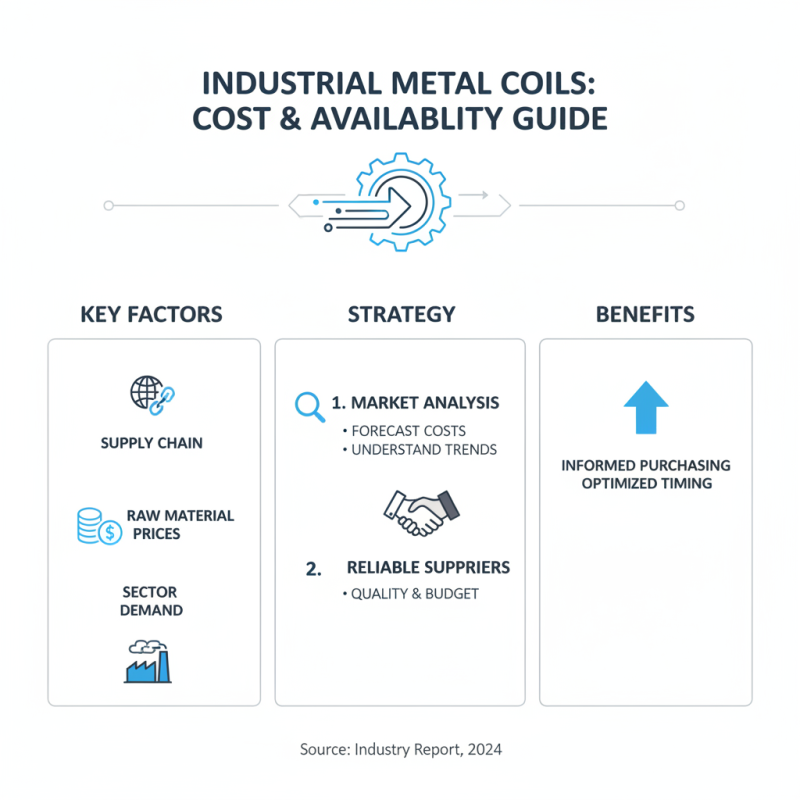

When selecting the right metal coil for industrial applications, understanding cost and availability is crucial. The market for metal coils can fluctuate based on supply chain challenges, raw material prices, and demand from various sectors. Evaluating these factors will help you identify reliable suppliers who can provide quality materials within your budget. Conducting a thorough market analysis not only aids in forecasting costs but also enables you to understand pricing trends, which can inform your purchasing decisions and timing.

Additionally, it's essential to assess the availability of different types of metal coils, as not all suppliers will carry the same inventory. Consider the lead times for delivery and the suppliers' capacity to fulfill orders promptly. Online platforms and industry networks can be valuable resources for locating suppliers with the materials you need in stock. By establishing strong relationships with reliable providers, you can secure better pricing options and ensure a steady supply chain, ultimately enhancing your operational efficiency and project timelines.