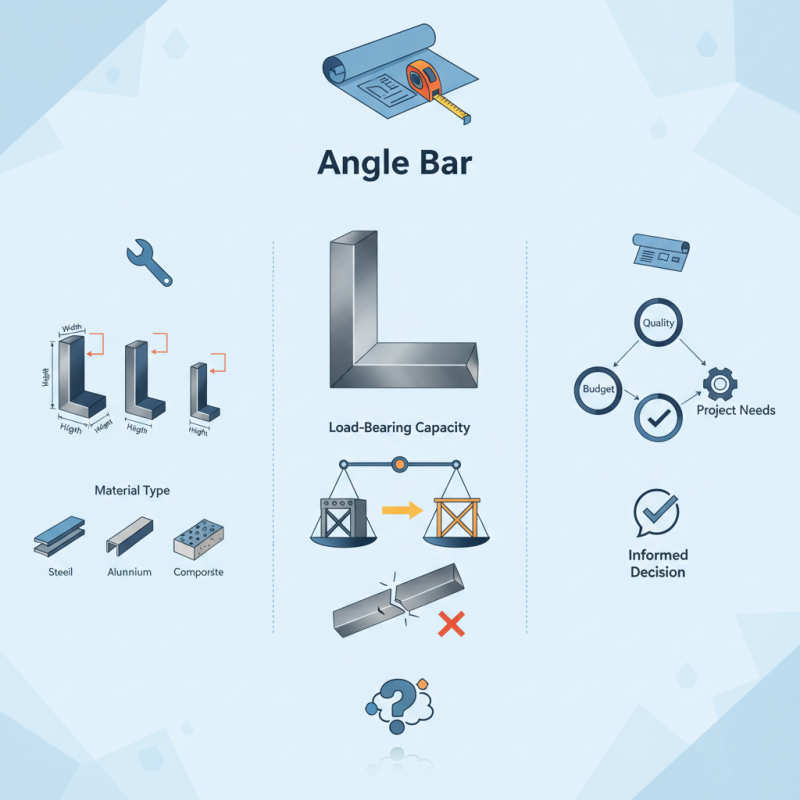

When engaging in construction projects, selecting the right materials is crucial. One key component often overlooked is the Angle Bar. An Angle Bar provides structural support and versatility, making it essential for various applications. However, many buyers overlook specific details that can impact their project.

Understanding the dimensions and specifications of an Angle Bar is fundamental. Size, thickness, and material type dictate the bar's load-bearing capacity. Selecting the wrong type can lead to underperformance or structural failure. It’s easy to assume that all Angle Bars are interchangeable, but this is not the case.

Moreover, project requirements can vary greatly. Sometimes, availability and cost can cloud judgment. Ensuring you choose the right Angle Bar involves balancing quality with budget and project-specific needs. Have you considered how these factors align with your goals? Reflecting on this question can guide you toward a more informed decision.

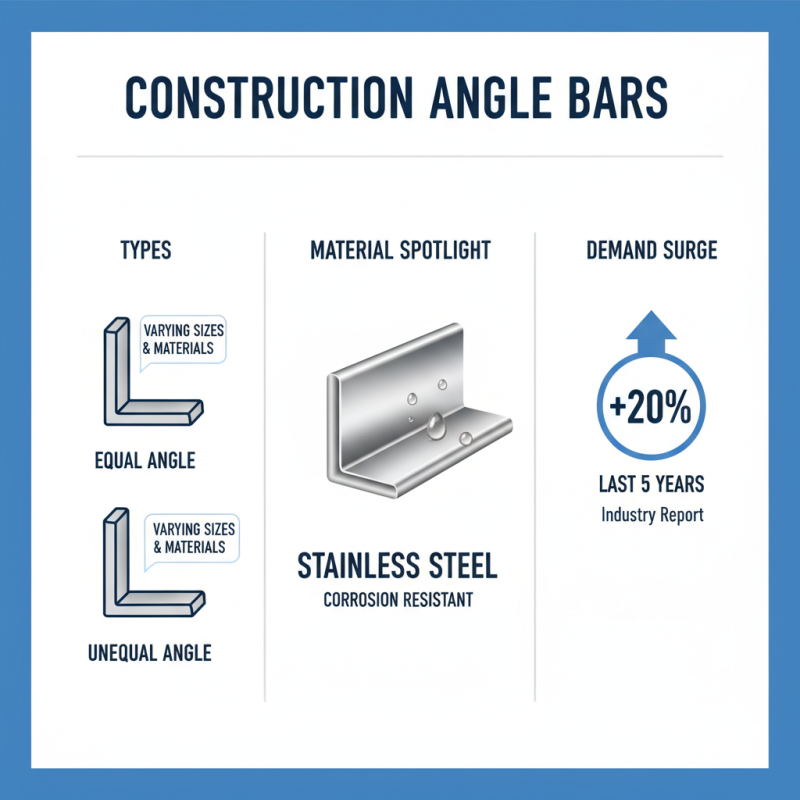

When choosing angle bars for construction, understanding their types is crucial. Angle bars come in various sizes and materials. The most common types include Equal Angle Bars and Unequal Angle Bars. Equal angle bars have equal legs, while unequal ones differ in length. According to a recent industry report, the demand for stainless steel angle bars has surged by 20% in the last five years due to their corrosion resistance.

Choosing the right material is key. Mild steel is popular for many applications. In contrast, aluminum angle bars are lightweight and resistant to rust. A study shows that 35% of construction professionals prefer aluminum for projects near water. However, one needs to consider the load-bearing capacity of different materials. Not all available options can support larger structures.

One often overlooked aspect is the finishing on angle bars. A rough finish can impact both aesthetics and performance. Surface treatment could affect longevity. A report highlighted that 40% of construction failures are linked to material selection, especially angle bars. It's essential to weigh the pros and cons carefully. Ensure you understand each type’s unique features before making a choice.

When selecting angle bars for construction projects, several key factors come into play. The material strength is crucial. Structural steel is commonly used. However, the grade of steel can vary. For instance, S235 and S275 grades offer different tensile strengths. Choosing the right grade affects durability and load-bearing capacity.

One important aspect is size. Common dimensions for angle bars range from 20mm to 200mm in leg length. The size you need will depend on the specific requirements of your project. Over-engineering might increase costs unnecessarily. On the other hand, underestimating can risk structural integrity. Always consider the load that will be placed on the bar.

Tips: Always calculate the anticipated load. Use structural analysis software if needed. This can help you avoid costly mistakes. Also, regularly review safety standards. They help ensure compliance and avoid project delays.

Additionally, consider the angle of the bar. Common angles include 90° and 45°. The angle affects the bar's functionality in a project. Some projects may require custom angles. This adds complexity and cost. Reflect on whether the design of your project truly necessitates these custom specifications, as it may lead to inefficiencies.

When selecting an angle bar for construction, load-bearing requirements are crucial. Different projects have varying demands. Some applications need high tensile strength. Others may require flexibility. Consider the specific needs of your project. Analyze the intended load: dead loads, live loads, and environmental factors.

Understand the material properties of the angle bar. Steel bars often deliver better performance than aluminum. However, weight considerations come into play. A lighter material might ease handling but reduce strength. Sizing also matters. A bar that’s too small might fail under pressure. One that’s too large can incur unnecessary costs.

Think about the installation process. Poorly selected angle bars can lead to structural issues. It’s essential to reflect on your choices. Consult with engineers when uncertain. They can help you navigate the complexities of load calculations. Prioritize safety and functional performance in your decision-making.

When selecting angle bars for construction, material quality and strength are crucial. Not all angle bars are created equal. A higher grade steel can significantly enhance the structural integrity of a project. Look for bars that meet specific industry standards. This ensures they can withstand stress and avoid deformation. However, not everyone checks these standards closely.

Inspecting the angle bar's surface is essential. A smooth finish often indicates better manufacturing processes. Rust and corrosion are red flags. They can weaken the steel over time. If you see imperfections, reconsider your choice. Strength testing is another step that’s sometimes overlooked. Conducting tests can reveal a bar's true capacity.

Pay attention to the weight of angle bars. Heavier bars are generally stronger, but not always. Balancing strength and weight is key. Sometimes, lighter bars seem appealing for ease of handling. But when it comes to load-bearing, they may not perform well. It’s easy to be swayed by costs too. Cheaper options might compromise safety. Always think critically about the long-term implications.

When budgeting for angle bar purchases in construction, cost-effectiveness is crucial. The price of steel fluctuates based on global demand and supply. A recent report from the World Steel Association indicates that steel prices increased by 30% over the last year. This underscores the importance of careful budgeting. Construction projects can easily exceed budget limits if costs aren't monitored closely.

Contractors must analyze various factors before purchasing angle bars. The right choice depends on size, grade, and quantity. A report from the American Institute of Steel Construction highlights that selecting the correct specifications can save up to 15% on material costs. However, many projects face overspending. Poor decisions often stem from inadequate pre-purchase research. Contractors sometimes choose lower-grade materials, unaware of long-term implications.

It's also essential to compare suppliers. Prices can vary significantly. In some cases, a slight difference in cost can result in significant savings for large orders. A detailed market analysis often reveals hidden costs associated with shipping and delivery. Many firms underestimate these aspects, leading to budget overruns. Overall, being thorough in your approach will yield better financial outcomes in the long term.

This chart displays the average cost per meter of various types of angle bars used in construction projects. Understanding the cost-effectiveness of each material can help in making informed decisions during budget planning.