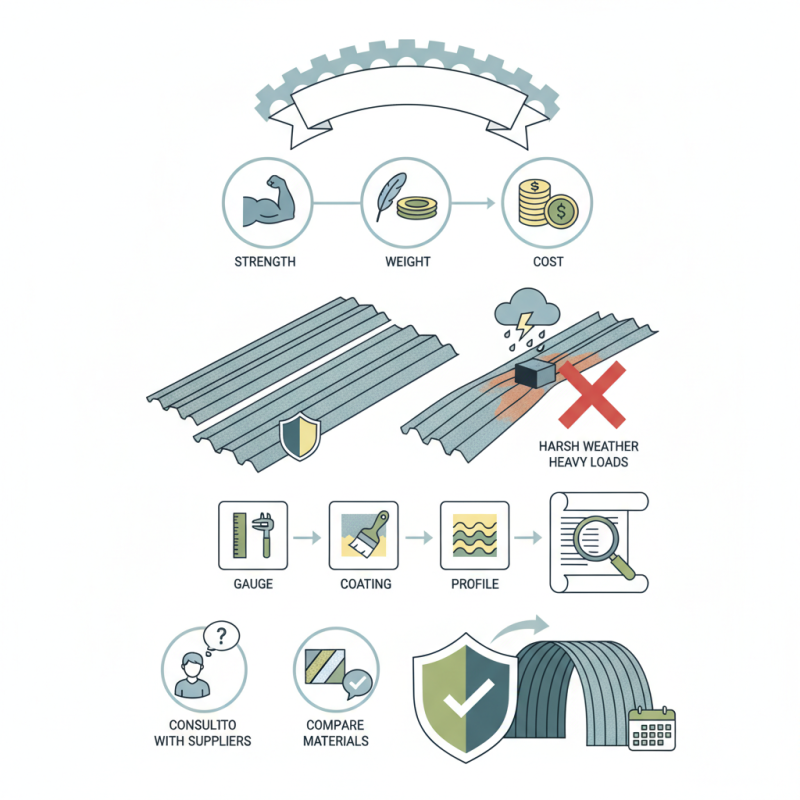

Choosing the right corrugated steel for your project can be challenging. Many factors influence this decision, including strength, weight, and cost. Expert in the field, John Smith, advises, "Selecting the appropriate corrugated steel is vital for ensuring project longevity." His words remind us of the importance of this choice.

Corrugated steel has applications in various industries, from construction to agriculture. It’s known for its durability and flexibility. However, not all corrugated steel is created equal. Some options may not withstand harsh weather or heavy loads. This inconsistency can lead to costly mistakes.

When considering your project needs, focus on specifications. Identify the required gauge, coating, and profile. These parameters significantly affect performance. Some contractors overlook these details, only to face unpleasant surprises later. It’s essential to consult with suppliers, compare materials, and ask questions. Making informed choices now can prevent regrets down the road.

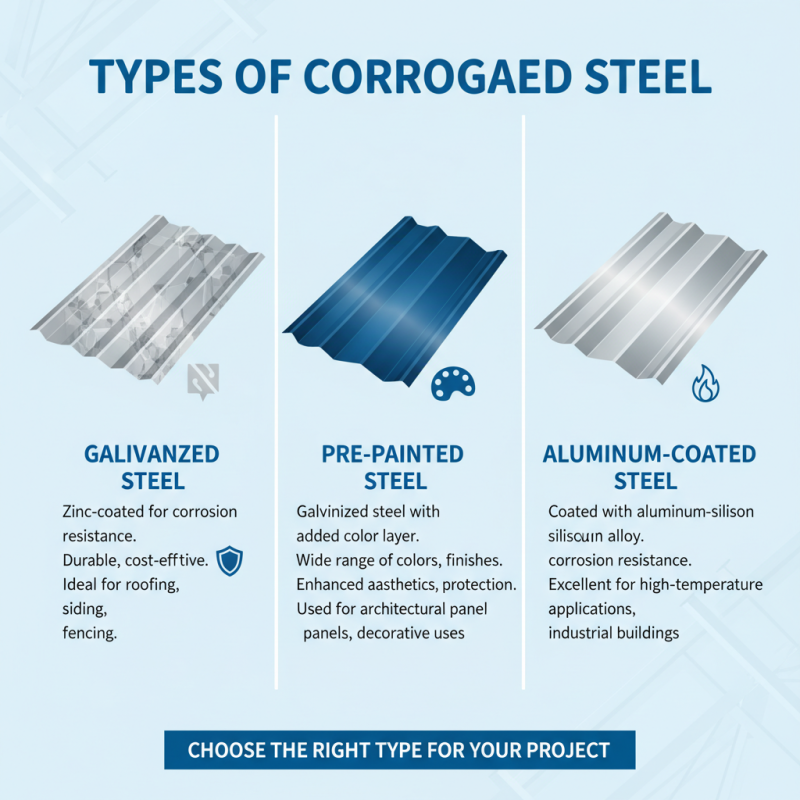

When selecting corrugated steel for your project, understanding the types is crucial. Corrugated steel comes in various profiles and thicknesses. The common types include galvanized, pre-painted, and aluminum-coated steel. Each type serves different applications, impacting performance and aesthetics.

Galvanized steel is coated in zinc to resist corrosion. This type is often used in roofing and siding. Data from industry reports show that galvanized steel can have a lifespan of over 30 years with proper maintenance. However, environmental factors like high humidity can accelerate rusting, which is a concern in some regions.

Pre-painted steel offers additional protection and aesthetic appeal. In a survey, 70% of builders preferred this option for its visual impact. The paint can chip or fade over time, requiring periodic touch-ups. Aluminum-coated steel provides excellent corrosion resistance and thermal properties. However, it may not be as widely available as other options. Choosing the right type depends on your specific needs and project conditions.

When choosing corrugated steel, thickness and gauge are crucial. The gauge measures the steel's thickness. A lower gauge indicates thicker steel. This detail significantly influences both strength and durability. Thicker steel can better withstand harsh conditions. It resists impact and deformation, which is vital for roofing and siding.

However, thicker steel is heavier and may require extra support. This can be a challenge during installation. Balancing thickness with the project’s needs is important. A project that demands high durability might overlook weight concerns. On the other hand, lighter gauge options might not provide the required strength.

Evaluating your project’s environment will guide you in choosing the right gauge. Areas prone to severe weather demand thicker options. Look at past performance in similar projects. Reflecting on previous choices can help refine your decision. Ultimately, the right thickness and gauge lead to better long-term results.

When choosing corrugated steel, coatings and treatments play a crucial role in corrosion resistance. A variety of options exist to enhance durability. Common coatings include galvanized finishes and organic paint systems. Galvanization adds a zinc layer, providing excellent sacrificial protection. It’s a proven method that many prefer. However, it may not offer the best long-term solution in highly corrosive environments.

Organic coatings, on the other hand, offer aesthetic appeal and additional protection. They can be tailored for specific conditions and colors. Yet, these coatings can wear off over time. Some may not be as effective in preventing corrosion as expected. It is essential to weigh the longevity of the coating against its initial cost. Not all projects need the same level of protection, so evaluating the environment is necessary.

Consideration of treatments is similarly important. Pre-treatments can enhance surface adhesion, improving longevity. However, these may not always deliver remarkable results. Regular inspections will become part of the maintenance routine. Insufficient attention to deterioration can lead to unexpected failures. Choices in coatings and treatments should therefore align closely with project requirements and environmental factors.

When selecting the right profile and shape of corrugated steel for structural applications, understanding your project's needs is crucial. The shape of the corrugation affects structural integrity and the material's performance. Common shapes include sinusoidal and trapezoidal profiles. Each has unique strength characteristics, impacting how they handle loads and resist deformation.

When budgeting for your steel project, calculating cost versus performance is crucial. It’s easy to fixate on the price per square foot. However, the long-term benefits often justify a higher initial investment. Consider the durability of corrugated steel. A cheaper option may save money upfront, but could lead to higher maintenance costs later on.

Next, evaluate your project’s specific needs. Will the structure face harsh weather conditions? Higher quality steel might be necessary. This choice could mean spending more now, but it ensures longevity and lower replacement costs down the line. Each project varies, making a cookie-cutter formula ineffective.

Keep in mind the overall design and application. A simple structure might not require top-tier materials. That said, reflect on your goals. Long-term performance can outweigh initial cost savings. Aim to strike a balance between your budget and what you truly need. Often, investing in quality now pays off significantly later.