Choosing the right Galvanized Sheet for your project can be daunting. According to Mark Reynolds, a leading expert in the industry, "The right material makes all the difference." When dealing with Galvanized Sheets, several factors come into play. You may need to consider thickness, coating weight, and finish. Each option serves different applications.

A project requiring durability might opt for a thicker Galvanized Sheet. It is essential to match the sheet's specifications with the project's requirements. However, many overlook these details, leading to costly mistakes. For instance, using a sheet with too thin a coating may result in premature corrosion.

Understanding the nuances of Galvanized Sheets is vital. The industry offers a range of choices, yet the best option often remains unclear. Take time to research and ask questions. This can significantly impact your project's overall success. Your choices now will shape the longevity and appearance of your work.

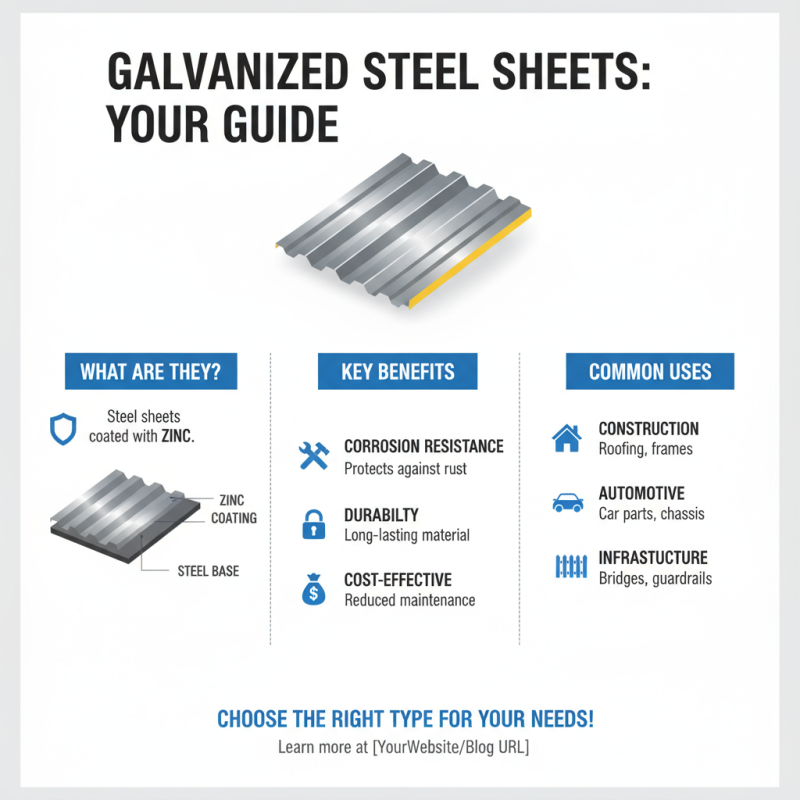

Galvanized sheets are essential in many projects. They are steel sheets coated with zinc. This coating protects against rust and corrosion. Understanding their basics can help you choose the right type for your needs.

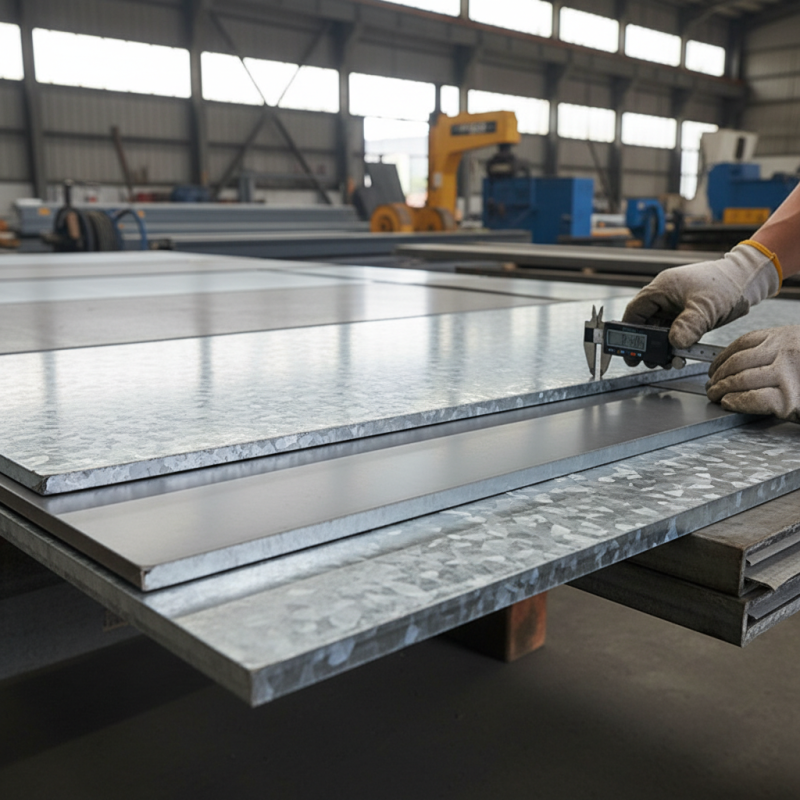

When selecting galvanized sheets, consider the zinc coating thickness. Thicker coatings offer better protection but are more expensive. Look for the ASTM specifications to determine the right grade. Some sheets may have imperfections like uneven coating or slight dents. Reflect on whether these flaws impact your project's integrity.

Tips: Always check for corrosion resistance ratings. This detail helps in outdoor projects. Also, consider the sheet’s dimensions carefully. Custom sizes can lead to waste and added costs. Measure twice. It prevents mistakes that can be hard to fix later on.

When selecting galvanized sheet steel, understanding the types available is crucial. There are two primary types: hot-dip galvanized and electro-galvanized. Hot-dip galvanizing involves submerging the steel in molten zinc. This method provides a thicker coating, making it suitable for outdoor applications. It is durable and corrosion-resistant. However, the finish may be rough, which could affect aesthetic projects.

Electro-galvanized sheets, on the other hand, use an electroplating process to apply a thinner layer of zinc. This results in a smoother finish, ideal for projects where appearance is important. However, it may not offer the same level of corrosion resistance as hot-dip options. It’s important to ponder the specific needs of your project. Thickness, finish, and intended use are key factors.

Sometimes, the choice isn’t clear-cut. You might find that hot-dip sheets could rust in certain conditions. Electro-galvanized steel can also wear out faster in harsh environments. It’s crucial to weigh the pros and cons carefully. Mistakes happen, and what seems best at first may not work in practice. Always consider testing a small sample before committing to a larger purchase.

When selecting galvanized sheet for a project, thickness and gauge matter deeply. Thickness affects durability. A typical gauge range is 10 to 30. A lower gauge means thicker sheet. Thicker sheets resist impact and corrosion better, ideal for heavy-duty applications. For roofing, a gauge between 24 and 26 is often enough. It balances strength and weight.

Project needs can be tricky. If you miscalculate, you might end up with sheets that are too flimsy. This could lead to structural failures over time. It’s crucial to evaluate your project’s requirements carefully. Assess environmental factors. Will the sheet face harsh conditions? Areas with moisture or severe weather benefit from thicker materials.

Don't overlook the weight factor. Heavier sheets may be more robust but can complicate handling. Consider if your structure can support the sheet's weight. Ask yourself if you really need extra thickness. Sometimes, a lighter gauge fits just fine. Reflect on your options before making a choice.

When selecting a galvanized sheet for your project, it's crucial to assess its corrosion resistance. Galvanization involves coating steel with zinc, which protects against rusting. However, not all galvanized sheets offer the same level of durability. Factors such as the thickness of the zinc layer play a significant role. Thicker coatings often provide better protection, but they can increase costs.

Environmental conditions also impact corrosion resistance. For example, coastal areas experience higher humidity and salt exposure, leading to faster corrosion. If you're working in such areas, it may be wise to opt for sheets with additional protective coatings. A thorough understanding of your specific environment can prevent future issues.

Durability is another key aspect to consider. How long do you expect the sheet to last? Cheaper options might save money initially, but they can lead to replacements sooner. Reflection on your project's lifespan will guide you toward the right choice. Mistakes here can lead to unnecessary expenses and safety risks. Choosing wisely requires a balance between budget, environment, and intended use.

Choosing the right galvanized sheet for your project involves various factors, particularly when it comes to surface finishing options. Aesthetic appeal can significantly influence the overall look of your work. It’s essential to select the right finish to complement your design. Finish options include smooth, embossed, and painted surfaces. Each has unique characteristics that can enhance the visual impact of your project.

Tips for selecting finishes: Consider the environment. Outdoor projects may need rust-resilient coatings. Indoor designs allow more flexibility. Texture and color can change the overall vibe. Metallic finishes may look sleek, while textured surfaces can offer a more rustic feel. Pay attention to how these choices interact with other materials.

It’s easy to overlook the importance of surface finishing. A simple galvanized sheet might look plain without the right treatment. Reflect on how different finishes resonate with your project goals. Are you aiming for elegance or ruggedness? Sometimes, the choice might feel uncertain. Take your time to visualize the end result. Balancing durability and aesthetic charm is key in achieving your vision.