When embarking on a construction project, one of the critical decisions lies in selecting the appropriate materials, particularly the iron sheet, which plays a vital role in structural integrity and aesthetics. According to a report from the Global Iron and Steel Institute, the demand for iron sheets has surged by over 15% in recent years, driven by rapid urbanization and infrastructure development. This increasing demand necessitates a well-informed approach to selecting the right iron sheet, emphasizing not just cost-effectiveness but also the quality, durability, and specific applications relevant to the project at hand.

Renowned industry expert Dr. Sarah Thomason, a leading materials scientist, emphasizes, "Choosing the right iron sheet requires a thorough understanding of both your project's requirements and the material properties available in the market." Dr. Thomason’s insights highlight the importance of evaluating the various types of iron sheets—galvanized, pre-painted, and corrugated—each serving distinct purposes and offering varied benefits. By carefully analyzing these factors and leveraging expert advice, construction professionals can make informed choices that enhance the performance and longevity of their projects, ultimately leading to successful outcomes within the competitive construction landscape.

When selecting the appropriate iron sheets for a construction project, it's essential to understand the various types available, each suited for specific applications. The two predominant types of iron sheets used in construction are galvanized iron sheets and color-coated iron sheets. Galvanized iron sheets, coated with a layer of zinc, offer enhanced resistance to corrosion, making them ideal for outdoor construction and roofing. According to industry reports, projects utilizing galvanized sheets can extend the lifespan of structural components by up to 20 years beyond those using untreated materials.

On the other hand, color-coated iron sheets provide both aesthetic appeal and functional advantages. These sheets come with a layer of protective paint, which not only prevents corrosion but also offers a range of colors and finishes suited for modern architectural designs. Reports indicate that color-coated iron sheets are gaining popularity in commercial and residential projects, attributed to their ability to improve thermal performance and reduce energy costs by reflecting sunlight. In regions where extreme weather conditions prevail, this feature can lead to a notable decrease in cooling costs—sometimes by as much as 10-15%, depending on the climate.

When selecting iron sheets for a construction project, evaluating their thickness and weight is crucial for ensuring structural stability. The thickness of an iron sheet directly impacts its strength and load-bearing capacity. Thicker sheets are generally more resistant to deformation and can support heavier loads, making them suitable for applications in high-stress areas such as roofs, frameworks, and heavy machinery enclosures. Conversely, while thinner sheets may be more manageable and less costly, they might be prone to bending or warping under pressure, which can compromise the integrity of the entire structure.

Additionally, the weight of the iron sheets affects not only the structural design but also the logistics of construction. Heavier sheets require more robust support systems and may increase transportation costs. On the other hand, lighter sheets can simplify handling and installation processes, but this often comes at the cost of overall strength. It’s essential to strike a balance between sufficient thickness and manageable weight, considering the specific requirements of the construction project, including environmental factors and safety standards. By carefully evaluating these parameters, builders can ensure that their choice of iron sheets meets both functional and structural demands effectively.

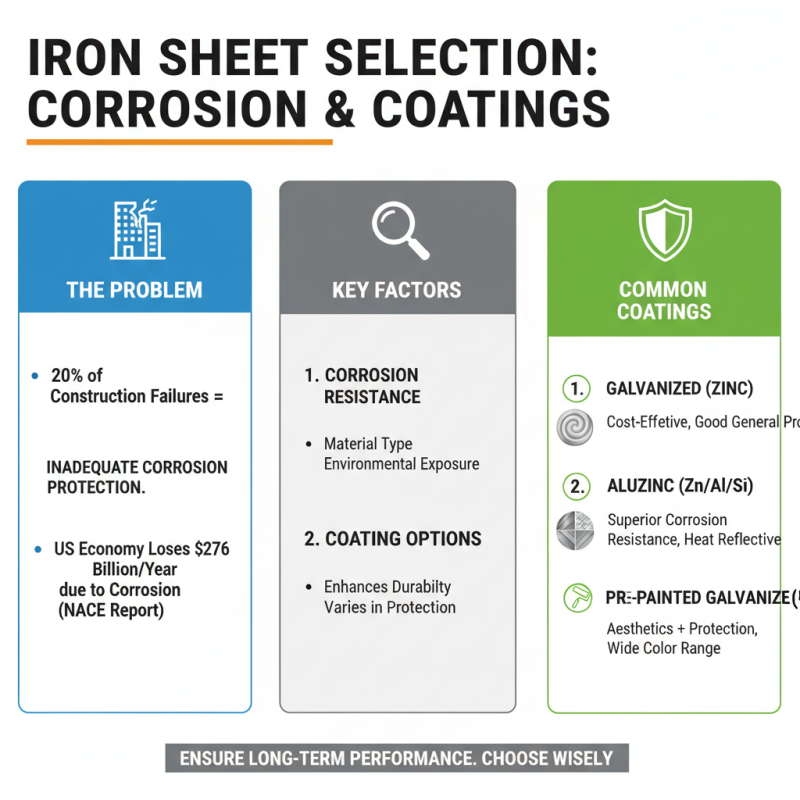

When selecting the right iron sheet for your construction project, assessing corrosion resistance and coating options is crucial. A significant percentage of construction failures can be attributed to inadequate corrosion protection. According to a report by the National Association of Corrosion Engineers (NACE), corrosion costs the U.S. economy nearly $276 billion annually, primarily due to premature failures of materials used in construction. Thus, understanding how different coatings affect the durability of iron sheets is essential for ensuring long-term performance.

One of the primary factors to consider is the type of coating applied to the iron sheets. Hot-dip galvanizing, for instance, provides a thick coating of zinc that offers excellent protection against rust and can extend the lifespan of the material significantly. Another option is paint systems that incorporate anti-corrosive additives, which can also enhance protection while allowing for aesthetic flexibility. Selecting the right coating not only helps in managing corrosion but can also reduce maintenance costs over time.

**Tips:** Always conduct a corrosion risk assessment specific to your project location, as environmental conditions such as humidity and salinity can greatly impact the effectiveness of coatings. Additionally, consult technical data sheets and reliability studies that outline the expected lifespan and performance of various coatings under different conditions, ensuring you choose a solution tailored to your needs. For optimal results, consider a combination of protective measures, as this can offer comprehensive defense against corrosion.

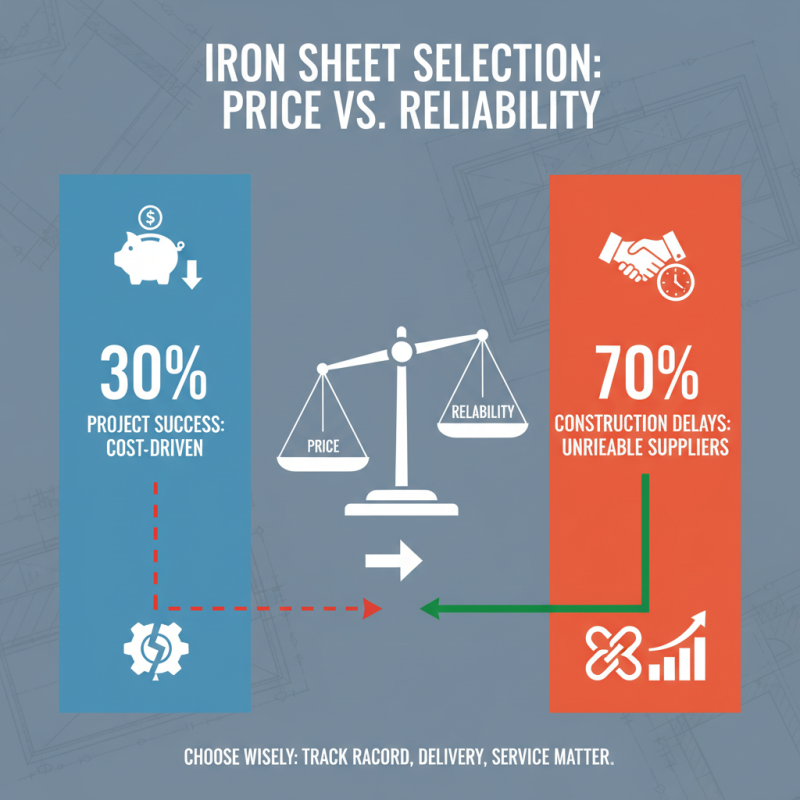

When embarking on a construction project, choosing the right iron sheet involves more than just selecting a cost-effective option. Supplier reliability is equally crucial, as it affects the project's overall success. According to industry statistics, approximately 70% of construction delays can be attributed to unreliable supplier practices. This underscores the importance of assessing not only the price but also the supplier's track record, delivery schedules, and customer service.

To ensure you select a reliable supplier, consider their experience in the market. Reports indicate that suppliers with more than five years of experience tend to have more stable operations and better customer relationships. Additionally, review their certifications and partnerships within the industry. Reliable suppliers often hold certifications that reflect their adherence to quality standards, which can also impact the long-term durability of the iron sheets you choose.

Tips: Engage with past clients of the supplier to gauge their satisfaction levels. Ask for testimonials or case studies that demonstrate the supplier's ability to meet timelines and provide quality products. Furthermore, it’s beneficial to request samples prior to making a bulk purchase. This not only helps assess the quality of the iron sheets but also allows you to ensure they meet your project’s specific requirements. Remember that investing time upfront in evaluating supplier reliability can save significant costs and headaches later in the construction process.

When selecting iron sheets for construction projects, it's essential to consider their environmental impact and sustainability. According to a report published by the World Steel Association, the steel industry accounts for approximately 7% of global greenhouse gas emissions. This highlights the importance of choosing products that are produced using sustainable methods, such as those that utilize recycled materials or energy-efficient processes. By opting for iron sheets made from recycled steel, which can reduce energy consumption by up to 75%, builders can significantly lessen their carbon footprint.

Additionally, the life cycle assessment (LCA) of construction materials reveals that iron sheets, when sourced responsibly, can contribute to sustainable building practices. The United Nations Environment Programme (UNEP) suggests that materials with a minimal environmental impact throughout their life cycle—production, transportation, use, and end-of-life disposal—are crucial in promoting sustainability in the construction sector. Thus, when selecting iron sheets, it is imperative to evaluate their sourcing, manufacturing practices, and potential for recycling to align with environmental goals and ensure compliance with increasing regulations on sustainability within the industry.