In the ever-evolving landscape of manufacturing and construction, metal coils have emerged as crucial components in a variety of applications. According to industry expert John Smith, a renowned specialist in metal processing, "The versatility of metal coils is unmatched; they serve as the backbone for many products we rely on daily." This underscores the significance of understanding the different types of metal coils available and their respective benefits in various sectors.

Metal coils come in various forms and materials, each suited for specific applications ranging from automotive parts to building structures. Their adaptability allows for a multitude of uses, enhancing efficiency in operations and offering cost-effective solutions. As manufacturers seek to optimize their processes, a comprehensive grasp of the essential metal coil types can provide valuable insights into selecting the right material for the job.

This guide aims to illuminate the most popular metal coil types, shedding light on their distinct characteristics and applications. By exploring these aspects, businesses can better navigate the challenges within the industry and make informed decisions that contribute to their success. Understanding the landscape of metal coils not only enhances operational performance but also opens doors to innovative possibilities in product development.

Metal coils are integral components across various industries, and understanding their types and characteristics is essential for making informed choices in applications. One of the most common types is galvanized steel coil, coated with zinc to enhance corrosion resistance. This makes it particularly suitable for outdoor applications like roofing and siding, where exposure to the elements is a concern. Additionally, the coating can improve paint adhesion, expanding its aesthetic potential.

Another notable type is stainless steel coil, valued for its strength and resistance to rust and staining. Often used in food processing and medical applications, stainless steel coils maintain hygiene and durability.

Aluminum coil, on the other hand, is lightweight, malleable, and often used in applications requiring high thermal conductivity, such as HVAC systems. Each type of metal coil has unique properties that cater to specific needs within construction, manufacturing, and engineering, making them essential for a wide range of applications.

Metal coils are integral components in various industries, each type serving distinct applications that enhance efficiency and functionality. For instance, copper coils are widely utilized in HVAC and plumbing systems due to their excellent thermal conductivity and resistance to corrosion. As the North America Copper Tubes Market suggests, these products are essential for creating reliable and energy-efficient systems. Furthermore, advancements in 3D printing technology are enabling the use of pure copper and copper alloys, broadening the scope of applications in manufacturing and production.

Aluminum coils, on the other hand, have gained traction in sectors like aerospace and automotive, driven by the material's lightweight nature and strength. The rise of aluminum in additive manufacturing showcases its potential to revolutionize production processes, making it a favored choice for modern engineering challenges. Similarly, stainless steel coils are vital in applications ranging from construction to food processing, offering durability and resistance to various environmental conditions. The growth of the stainless steel market underlines its key role across diverse industries, emphasizing the importance of selecting the right metal coil type based on specific application needs.

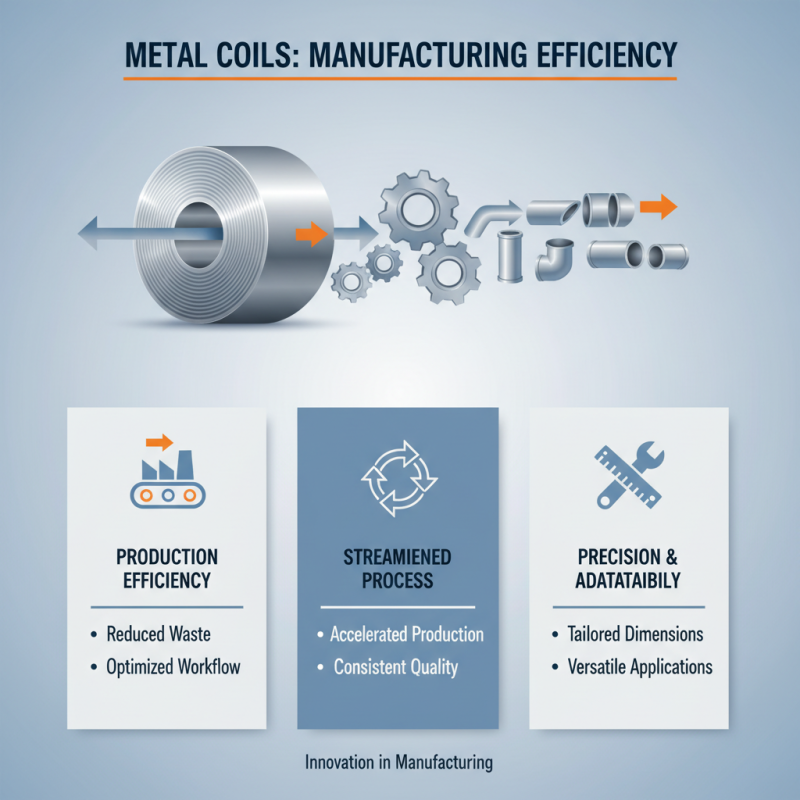

Metal coils play a pivotal role in various manufacturing processes due to their unique characteristics and adaptability. One of the primary benefits of using metal coils is their efficiency in production. Metal coils can be rolled to desired dimensions and fed directly into machines, reducing waste and optimizing the manufacturing workflow. This streamlined process not only accelerates production but also ensures consistency in quality, as the coils can be manufactured to precise specifications.

Moreover, metal coils are versatile and can be used in a wide array of applications, ranging from automotive parts to construction materials. Their capacity to be further processed, such as bending and forming, allows manufacturers to create intricate designs without compromising material integrity. Additionally, using metal coils can lead to cost savings; bulk purchasing and minimalistic cutting reduce material costs, while the durability of metal ensures a long lifespan, lowering the need for frequent replacements. Overall, the advantages of using metal coils are significant, making them an essential component in modern manufacturing.

When comparing metal coil materials, steel and aluminum are often at the forefront due to their unique properties and applications. Steel coils, known for their strength and durability, are commonly utilized in construction, automotive, and heavy machinery industries. However, the recent rise in tariffs on steel imports significantly affects pricing and availability in the market. With U.S. tariffs on steel now reaching up to 50%, manufacturers must strategize their sourcing to mitigate cost increases and maintain competitiveness.

On the other hand, aluminum coils offer a lightweight alternative that is gaining traction across various sectors, especially in aerospace and automotive applications. The advantages of aluminum include its resistance to corrosion and excellent conductivity. Despite recent tariffs impacting aluminum costs, the ongoing innovations in aluminum manufacturing, particularly in additive technologies, suggest that its usage will continue to expand, fostering growth in these high-tech industries.

Tips: When selecting metal coils for your project, consider both material properties and market conditions. Keeping abreast of tariff updates can help in budgeting and sourcing decisions, ensuring you choose a material that aligns with both your performance needs and financial considerations. Always consult with suppliers about the latest pricing impacts due to trade policies.

Future trends in metal coil technology point towards significant advancements that will enhance efficiency, sustainability, and applications across various industries. The demand for metal coils, such as hot rolled coil (HRC) steel, continues to grow, driven by innovations in processing techniques and the integration of smart materials. The development of lightweight, high-strength materials is expected to revolutionize applications in automotive and construction, catering to the industry's need for both performance and energy efficiency.

Moreover, the evolving landscape of coil coatings is anticipated to play a crucial role in the market, with expected growth in demand forecasted to reach USD 2.1 billion by 2035. These coatings not only enhance the durability and aesthetic appeal of metal products but also contribute to energy savings and sustainability initiatives. As manufacturers increasingly adopt advanced technologies, such as 3D printing and additive manufacturing, the potential for customized and complex geometries in metal coils expands, paving the way for innovative applications in emerging sectors.

| Coil Type | Material | Applications | Benefits | Future Trends |

|---|---|---|---|---|

| Galvanized Steel Coil | Steel with Zinc Coating | Construction, Automotive, Home Appliances | Corrosion Resistance, Durability | Increased Coating Technologies, Sustainability |

| Aluminum Coil | Aluminum Alloy | Packaging, HVAC, Transportation | Lightweight, Non-Corrosive | Recycling Innovations, Energy Efficiency |

| Stainless Steel Coil | Stainless Steel | Food Processing, Medical Equipment | Hygiene, Strength | Smart Manufacturing, Biodegradable Materials |

| Copper Coil | Copper | Electrical Wiring, HVAC Systems | Excellent Conductivity, Anti-Corrosive | Increased Recycling Rates, Conductivity Enhancements |

| Tinplate Coil | Steel with Tin Coating | Food Cans, Beverage Containers | Corrosion Resistance, Food Safety | Eco-Friendly Coating Trends, Reduced Waste |