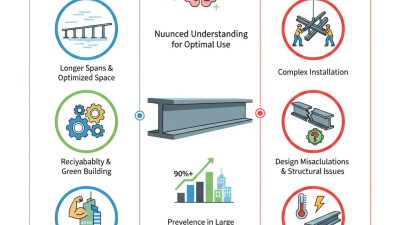

Working with structural steel is an essential part of modern construction. It provides strength and stability to various structures, from skyscrapers to bridges. However, working with structural steel comes with its own set of challenges. Understanding these challenges is crucial for any project manager or engineer in the field.

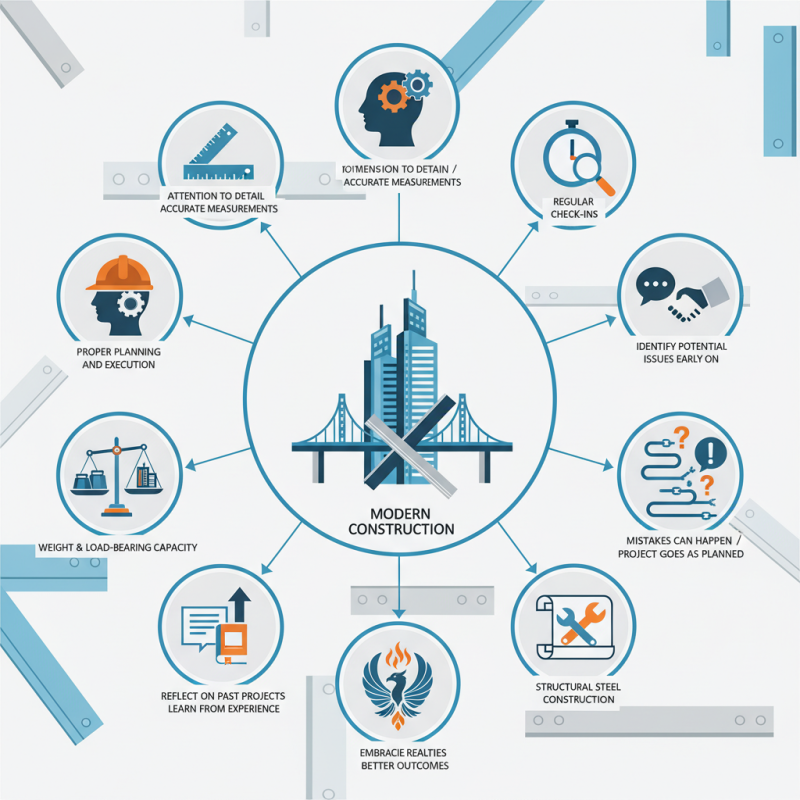

When dealing with structural steel, attention to detail is paramount. Proper planning and execution can prevent costly mistakes. For instance, accurate measurements can save time and resources. It’s also important to consider the weight and load-bearing capacity of structural steel beams. Engineers must reflect on past projects to learn from their experiences.

Communication is another key element in working with structural steel. Team collaboration ensures that everyone is on the same page. Regular check-ins can help identify potential issues early on. Mistakes can happen. So, understand that every project may not go as planned. Embracing these realities can lead to better outcomes for future endeavors in structural steel construction.

Understanding structural steel is crucial for any construction project. This material plays a vital role in ensuring the safety and stability of buildings. Its high strength-to-weight ratio makes it a preferred choice. However, working with structural steel requires careful planning and knowledge.

One essential tip is to understand the different types of structural steel available. Each type has unique properties and applications. For instance, some grades are better suited for high-stress areas. Knowing these details can significantly impact your project’s success. Communication with your team is key. Misunderstandings can lead to costly mistakes.

Another important aspect is proper welding techniques. Poor connections can weaken the structure. Always ensure that welders follow industry standards. Inspecting these welds regularly helps catch issues early. Remember, structural steel requires maintenance, too. Over time, corrosion can occur, which needs addressing to prolong the material's life. Understanding these nuances can elevate your construction project.

Working with structural steel requires strict adherence to safety practices. One crucial aspect is ensuring everyone wears the right personal protective equipment (PPE). This includes hard hats, gloves, and steel-toed boots. Each worker should check their gear before starting the day. It’s easy to overlook, but proper equipment can prevent serious injuries.

Another essential safety practice involves maintaining a clean work area. Remove any debris or tools that could pose a tripping hazard. This simple task can often be neglected in busy environments. It’s important to remind the team to stay focused. Distracted workers can lead to accidents involving heavy equipment.

Regular safety meetings also play a vital role. Use them to discuss potential hazards and share experiences. Encourage open communication about safety concerns. Reflecting on past incidents can promote a safer work culture. It’s natural to be complacent, but staying vigilant is key to protecting everyone on the job.

Selecting the right type of structural steel for your project is crucial. Consider the environment where the steel will be used. Will it face heavy loads or corrosive conditions? Different types of steel offer varying strength and resistance. For instance, carbon steel is commonly used for buildings due to its high tensile strength. However, it may not perform well in marine environments.

Stainless steel offers better corrosion resistance. This makes it ideal for coastal applications or areas with high humidity. On the other hand, alloy steel can provide specific performance features, such as improved hardness. These characteristics can help prevent future failures. Always assess the specific needs of your project.

Don’t forget to factor in cost. Choosing a more expensive type of steel might seem unnecessary upfront. However, it could save you from costly repairs down the line. Balancing initial investment and long-term benefits requires careful thought. Sometimes, using a cheaper option leads to future issues. Make sure to consider all aspects before making your final decision.

When working with structural steel, understanding fabrication and assembly is crucial. Proper techniques ensure safety and durability. One essential tip is to maintain precision in measurements. Even a minor error can lead to major structural issues. Use reliable measuring tools to verify every dimension before cutting or welding.

Another important aspect is effective communication among team members. Clear dialogue helps prevent misunderstandings during the assembly process. Discrepancies in interpretation can cause delays and costly rework. It is wise to hold regular briefings and progress checks. Flaws may arise without constant oversight. A helpful practice is to review work regularly.

Lastly, keep an eye on finishing processes. Rust and corrosion can compromise structural integrity. Applying protective coatings is a vital step. However, the application methods matter greatly. Inadequate surface preparation often leads to peeling and failure. Reflect on past projects to improve current practices. Learning from failures ensures progress and better outcomes in future endeavors.

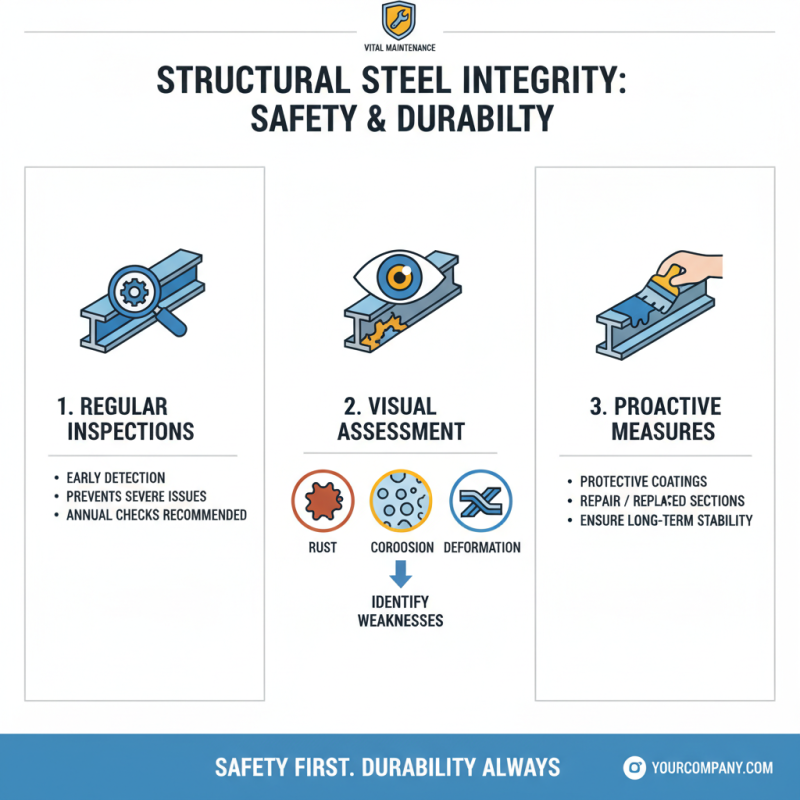

Inspecting and maintaining the integrity of structural steel is vital for ensuring safety and durability. Regular inspections help identify potential issues early. Use visual inspections to check for rust, corrosion, and deformation. A close look can reveal weaknesses before they become severe.

Consider scheduling inspections at different intervals. For example, perform detailed inspections every six months and cursory checks monthly. Maintain a log of your findings. This log can help track changes over time. It can also guide necessary maintenance actions.

Don't forget about the environment. Moisture and pollution can accelerate deterioration. Protective coatings can serve as a barrier against environmental damage. Ensure you refresh these coatings regularly. Utilize non-destructive testing methods for deeper insight. Techniques like ultrasonic testing can uncover hidden flaws. A proactive approach is essential for structural steel integrity.