Choosing the right Checker Plate for your projects is crucial. This lightweight yet durable material has various applications across industries. Many people overlook the unique properties of Checker Plate and its potential benefits.

Checker Plate is often used for flooring, ramps, and stair treads. Its raised pattern provides traction, making it safer for high-traffic areas. However, not all Checker Plates are created equal. Some may not offer the strength or slip resistance needed for specific uses.

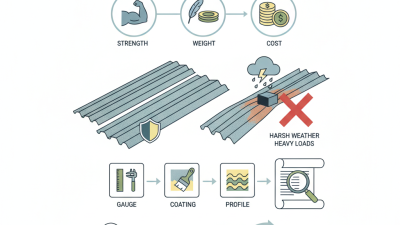

Consider the intended application when selecting a Checker Plate. The thickness and material type can greatly affect performance. Sometimes it’s easy to choose based on price alone, which could lead to regrets later. It’s essential to balance cost with quality to ensure the chosen Checker Plate meets all project demands.

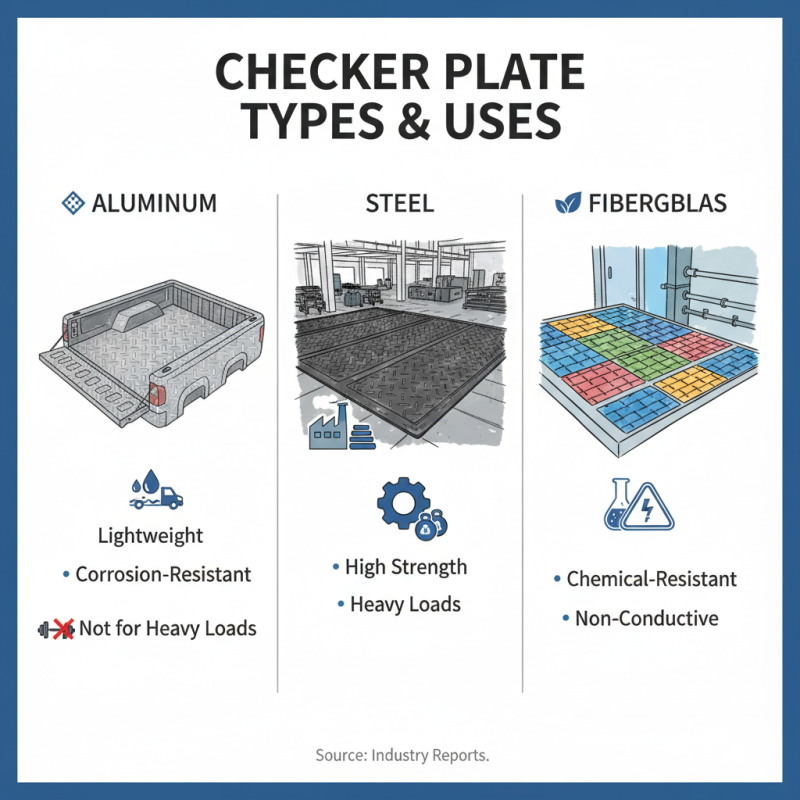

Checker plates, also known as diamond plates, come in various types and materials, each suited to specific applications. Common materials include aluminum, steel, and fiberglass. According to industry reports, aluminum checker plates offer a lightweight and corrosion-resistant option, making them ideal for truck beds and flooring in wet environments. However, they may not handle heavy loads as effectively as their steel counterparts.

Steel checker plates are robust and provide excellent load-bearing capacity, which is crucial for industrial settings. A report by the Global Steel Alliance indicates that approximately 60% of construction projects utilize steel due to its strength and durability. Yet, it's essential to consider that steel is heavier and can be prone to rust if not treated properly.

When choosing the right checker plate, aesthetics may also play a role. Fiberglass options can provide a non-slip surface and are often used in marine applications. Understanding the environment where the checker plate will be used is vital. For instance, wet or high-traffic areas may benefit from aluminum or fiberglass due to their superior grip and lightweight nature. It’s a balancing act between strength, weight, and safety features.

When selecting checker plates for your project, evaluating thickness and load-bearing capacity is crucial. Industry standards suggest that a thickness of 3 mm can handle approximately 300 kg per square meter. However, this can vary. Projects needing higher load capacities should consider plates over 6 mm thick. These thicker plates can support more weight and resist deformation under pressure.

Load-bearing capacity is not solely about thickness. It also involves the quality of the material used. Reports indicate that materials with higher tensile strength provide better performance. A thicker plate made from low-strength material may fail under stress, while a thinner, high-quality plate might excel. The type and placement of support structures also play significant roles.

Potential miscalculations can lead to significant issues. For instance, a common mistake occurs when projects underestimate dynamic loads. Equipment or vehicles in motion can exert forces much greater than static loads. This oversight can lead to inadequate support and structural failure. Always cross-reference load capacities against actual project specifications to avoid these pitfalls.

This chart displays the load-bearing capacities of checker plates with varying thicknesses. As the thickness of the plate increases, the load-bearing capacity also improves significantly, making it essential to choose the right thickness based on your project's specific requirements.

When choosing a checker plate, assessing surface texture is vital. The texture affects grip and safety. According to the American National Standards Institute (ANSI), a texture with adequate grip can reduce slip accidents by up to 30%. This is crucial for projects in high-traffic areas, like factories or warehouses. If the texture is too smooth, the risk increases.

Anti-slip features vary between different types of checker plates. Some materials offer superior grip, making them suitable for outdoor use. Studies show that patterns with larger diamonds tend to provide better traction. However, these may also accumulate dirt, affecting performance over time. Consider how frequently the surface will be cleaned.

Another common oversight is material choice. While aluminum is lightweight and corrosion-resistant, it can lack the slip resistance needed in certain environments. Steel offers better traction but can rust without proper coating. Evaluating the specific requirements for each project can minimize mistakes. Your choice of checker plate should align with both safety and functionality. Balancing these features can be challenging but essential for long-lasting results.

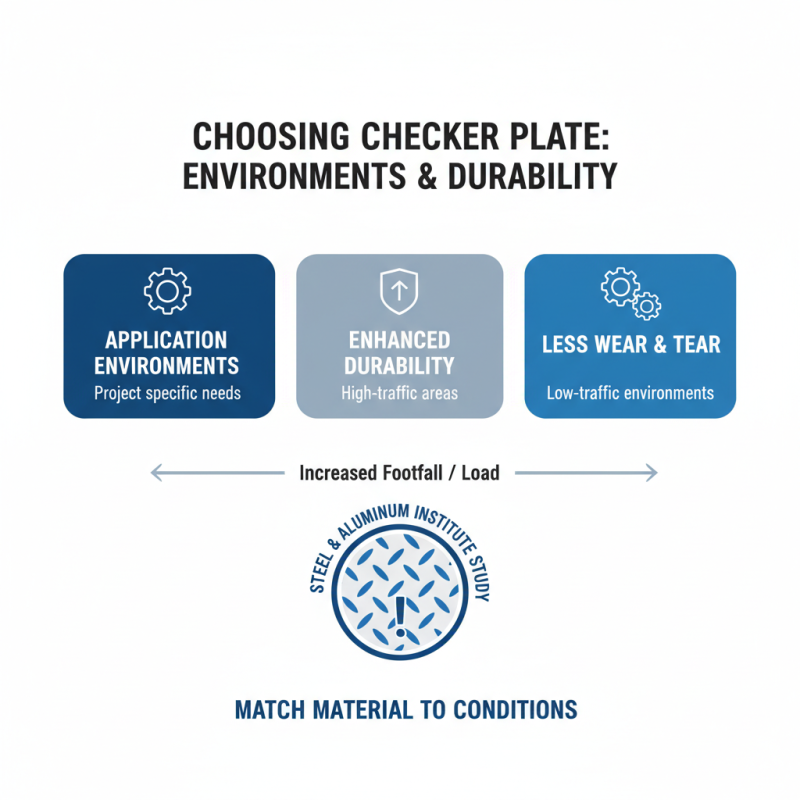

Choosing the right checker plate involves understanding various application environments. Each project has specific requirements dictated by the environment it operates in. For instance, a study by the Steel and Aluminum Institute indicates that checker plates used in high-traffic areas need enhanced durability. These plates often face more wear and tear.

In harsh environments, such as coastal areas, corrosion resistance is crucial. Low-grade materials can fail quickly in such conditions. A report from the International Metal Workers Federation points out that nearly 30% of construction failures occur due to improper material selection. This is a significant issue.

Additionally, consider the potential for heavy loads in industrial settings. The load-bearing capacity of checker plates varies. Miscalculating the appropriate thickness could result in structural failure. It’s not just about appearance; it’s about performance. Reflecting on past projects can lead to better decisions. Proper research can save time and costs down the line.

Choosing the right checker plate for your project involves careful budgeting and sourcing. Many factors influence the total cost. According to a recent market analysis, prices for checker plates can vary by up to 30% depending on material type and thickness. Steel remains the most common choice, but aluminum offers benefits like lighter weight and corrosion resistance. These factors impact overall project costs.

When budgeting, it's essential to account for potential price fluctuations. Sheets purchased in bulk can lead to significant savings. However, not all suppliers live up to their promises. Recent studies indicate that 40% of construction projects exceed their budget due to unexpected material costs.

*Tips*: Always ask for samples before making a bulk purchase. This helps avoid lower-quality materials. Also, consider sourcing from local suppliers. This can reduce freight costs and improve delivery time. Sometimes, opting for a less popular material can yield better pricing without compromising quality. Evaluate all options to ensure the best fit for your needs.

| Dimension (mm) | Material Type | Standard Price ($/m²) | Applications | Sourcing Options |

|---|---|---|---|---|

| 2500 x 1250 | Aluminum | 15.00 | Flooring, Ramps | Local Supplier, Online Marketplace |

| 3000 x 1500 | Steel | 10.00 | Industrial Platforms | Wholesale Distributors |

| 2000 x 1000 | Stainless Steel | 25.00 | Food Industry, Chemical Plants | Manufacturers, Importers |

| 1500 x 750 | Plastic | 8.00 | Temporary Structures | Retail Stores, Online Options |