Choosing the right Steel Tube for your project can feel daunting. Industry expert John Stevens emphasizes, “The quality of your steel tube can make or break your project.” Selecting a Steel Tube involves numerous considerations, including dimensions, material, and intended use. Each decision impacts the overall project outcome.

Steel Tubes serve various purposes in construction and manufacturing. A wrong choice could lead to structural failures. It's crucial to identify specific project needs before making a purchase. Sometimes, the perfect Steel Tube may not be readily available. In such cases, waiting for the right option is better than rushing.

Moreover, it’s essential to reflect on potential long-term effects. Inadequate materials can result in increased costs later. Always prioritize quality over price. The right Steel Tube could ensure durability and safety. Remember, thoughtful selection today fosters successful projects tomorrow.

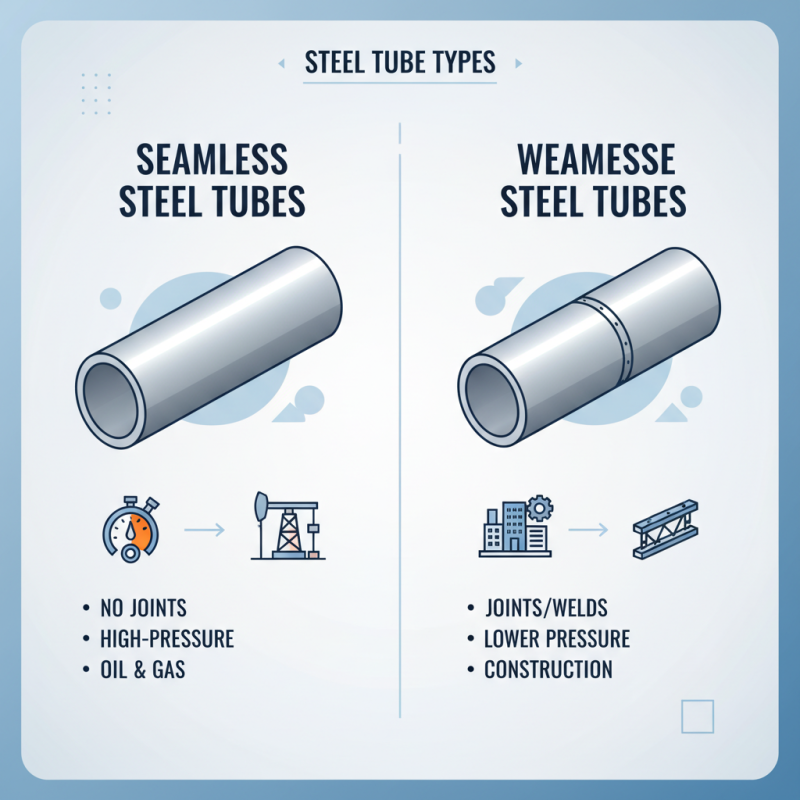

When selecting steel tubes for a project, understanding the various types available is crucial. Steel tubes vary significantly in terms of structure and application. For instance, seamless tubes are ideal for high-pressure applications due to their lack of joints. They are commonly used in oil and gas industries. In contrast, welded tubes are used in construction. They are easy to fabricate and have lower costs. However, a welded tube may not withstand high pressures effectively.

Another popular option is the square and rectangular steel tube. These shapes provide excellent strength and stability. They are used in structural applications and for making frames for various constructions. It's important to choose the right dimensions and wall thickness for the intended load. Sometimes, designers overlook these details. A tube that looks robust might not be suitable for your specific requirements.

Corrosion resistance is another factor worth considering. Galvanized steel tubes can offer protection against rust. This makes them suitable for outdoor applications. However, one must realize that not all environments are the same. Underestimating environmental factors could lead to premature failure. Therefore, evaluating the specific needs of the project is essential. Each type of tube has its pros and cons, which require careful consideration.

Choosing the right steel tube for your project requires consideration of various key factors. The material's strength and durability are paramount. Steel tubes come in different grades and specifications, which are critical for load-bearing applications. According to industry reports, structural steel tubes can hold up to 25% more weight than standard options. Knowing the project requirements is essential.

Dimensions also play a crucial role. The diameter and wall thickness influence the tube's performance. A thicker wall may offer increased stability, but it also adds weight. This balance is often overlooked. Projects occasionally compromise on these specs to reduce costs, leading to issues later. Always assess the project's structural needs against the tube's specifications.

Tip: Consider the environmental factors. Corrosion resistance is vital, especially in outdoor applications. Coatings can enhance durability but may increase costs. Review your budget carefully. Remember, a small investment in the right steel tube can save significant expenses in repairs or replacements over time. It's worth reflecting on the long-term implications of your material choices.

| Dimension | Material Grade | Wall Thickness (mm) | Weight (kg/m) | Application |

|---|---|---|---|---|

| 50 x 50 | S235JR | 3.0 | 5.0 | Construction |

| 75 x 75 | S355J2 | 4.5 | 7.8 | Industrial |

| 100 x 100 | ST37-2 | 5.0 | 10.0 | Furniture |

| 120 x 60 | S235JRG2 | 3.5 | 9.0 | Structural |

| 40 x 20 | Q195 | 2.0 | 3.9 | General Use |

When selecting steel tubes for construction, understanding industry standards is crucial. Various organizations have established specifications that guide the selection process. For instance, ASTM A500 outlines the requirements for cold-formed welded and seamless carbon steel structural tubing. Compliance with these standards ensures safety and performance.

Certain dimensions matter. For example, a standard steel tube may have wall thicknesses ranging from 0.250 inches to 0.500 inches, affecting load-bearing capacity. In construction, these attributes aren’t trivial. An inappropriate choice can lead to structural failures or safety hazards.

Tips: Always refer to the latest specifications before making a purchase. Verify each tube's quality with appropriate certifications.

Another important specification is ASTM A53, which covers steel pipe suitable for various applications. Not adhering to this standard could result in unsatisfactory durability. Maintain awareness of additional state and local regulations too. Ignoring them can complicate project timelines.

Tips: Keep updated with regional building codes. Double-check your selections with professionals.

When evaluating the price of steel tubes, budget considerations play a vital role. Industry reports indicate that steel prices fluctuate based on various factors. In recent years, costs have seen an average increase of 15% annually. Such data is crucial when formulating a budget for your project. Depending on the type of steel tube, prices can range widely. For instance, seamless tubes may cost between $2 to $4 per pound, while welded tubes are typically less expensive.

It's essential to analyze not just the immediate cost, but long-term expenses too. Steel tubes may require maintenance and can affect the overall project lifetime. A report from the Steel Manufacturers Association highlights that the lifecycle cost can impact project budgets significantly. Neglecting long-term durability might lead to unexpected future costs.

Furthermore, the intended application of the steel tube can influence its price. Specialty tubes designed for specific environments often come at a premium. Builders need to weigh their options carefully. Are the additional costs justified? Sometimes a cheaper option might lead to higher expenses down the line. Consider the balance between cost and quality to make an informed choice, ensuring it aligns with your budget constraints.

Steel tube production plays a significant role in the industry's sustainability efforts. The process requires substantial energy and emits greenhouse gases. Many factories are exploring greener technologies. Recycling steel is a vital part of this shift. It reduces the need for raw materials and lessens waste.

While steel is durable and long-lasting, its extraction and processing can negatively impact the environment. Original raw material mining disturbs ecosystems and uses large amounts of water. Manufacturers are now focusing on reducing energy consumption and waste. Innovations such as electric arc furnaces show promise. They can lower emissions and enhance energy efficiency.

Consumers have a responsibility too. They should seek out information about the steel tubes they purchase. Choosing sustainably-produced products can drive positive change. Not every production method is perfect yet. It requires continuous improvement and commitment from both producers and buyers. Awareness and action are key to fostering a more sustainable future in steel production.