Metal sheets are integral components in a multitude of industries, serving diverse functions from structural applications to aesthetic enhancements. As John Smith, an expert in metallurgy, aptly stated, "The versatility of metal sheets allows them to adapt and transform within countless applications, making them fundamental in modern manufacturing." This statement encapsulates the essence of metal sheets, which can be found in everything from automotive bodies to construction materials.

In today's rapidly evolving industrial landscape, the demand for metal sheets has surged, fueled by innovations in technology and design. The array of metals available—ranging from steel and aluminum to copper and titanium—each offers unique properties, thus broadening their applications across sectors such as aerospace, construction, and electronics. Metal sheets can be cut, bent, and shaped to meet specific requirements, further emphasizing their flexibility in the manufacturing process.

Furthermore, the sustainability aspect of metal sheets cannot be overlooked. With the increasing focus on eco-friendly practices, industries are turning to metal sheets for their recyclability and durability, which contribute to the reduction of waste and resource consumption. In conclusion, understanding the significance and usage of metal sheets is essential for anyone engaged in or studying the manufacturing and construction sectors.

Metal sheets are flat pieces of metal that are produced by various processes such as rolling, forging, and extrusion. They come in different thicknesses and can be made from a range of metals including steel, aluminum, copper, and more. One defining characteristic of metal sheets is their malleability, which allows them to be shaped and formed according to the specific needs of different applications. Additionally, their strength and durability make them suitable for use in various environments, from construction to manufacturing.

In different industries, metal sheets are utilized for diverse purposes. In construction, they can be used for roofing, wall cladding, and structural components. In manufacturing, they serve as components in machinery, vehicles, and appliances. The versatility of metal sheets makes them a crucial material in both commercial and industrial applications.

Tips: When selecting metal sheets for your project, always consider the specific properties needed for your application, such as corrosion resistance or thermal conductivity. Additionally, it’s essential to ensure that the metal sheet’s thickness is appropriate for the intended use to maintain structural integrity. Remember to consult industry standards to ensure compliance and optimize performance.

Metal sheets are thin, flat pieces of metal that are used across a myriad of industries for various applications such as construction, manufacturing, and automotive. The production of metal sheets involves a selection of common materials, which significantly impact their functionality and applicability in different sectors. Among the most popular metals used are steel, aluminum, copper, and brass. According to a report by IBISWorld, steel production alone accounted for over 45% of the global metal sheet market in 2022, underscoring its primary role in structural applications.

Aluminum comes in a close second due to its lightweight properties and corrosion resistance, making it ideal for industries like aerospace and packaging. Copper, known for its excellent electrical conductivity, is increasingly utilized in electronic components, whereas brass, an alloy of copper and zinc, is favored for its aesthetic appeal and mechanical properties, particularly in plumbing fixtures and decorative applications. The choice of material considerably influences the sheet's performance, durability, and cost.

Tips: When selecting a metal sheet for a project, consider factors such as weight, strength, and corrosion resistance based on the specific application. Additionally, consulting industry reports can provide valuable insights into current trends and material performance. Always ensure to assess the environmental impact of the materials being used, as sustainability practices in metal production are gaining importance.

| Material Type | Common Applications | Thickness Range (mm) | Industries |

|---|---|---|---|

| Aluminum | Aerospace, Automotive, Construction | 0.2 - 10 | Construction, Transportation |

| Stainless Steel | Kitchen Equipment, Medical Devices, Architecture | 0.3 - 12 | Food Industry, Medical |

| Carbon Steel | Manufacturing Machinery, Automotive Parts | 0.5 - 20 | Transportation, Manufacturing |

| Copper | Electrical Wiring, Plumbing | 0.3 - 15 | Electrical, Construction |

| Titanium | Aerospace Components, Medical Implants | 0.5 - 10 | Aerospace, Medical |

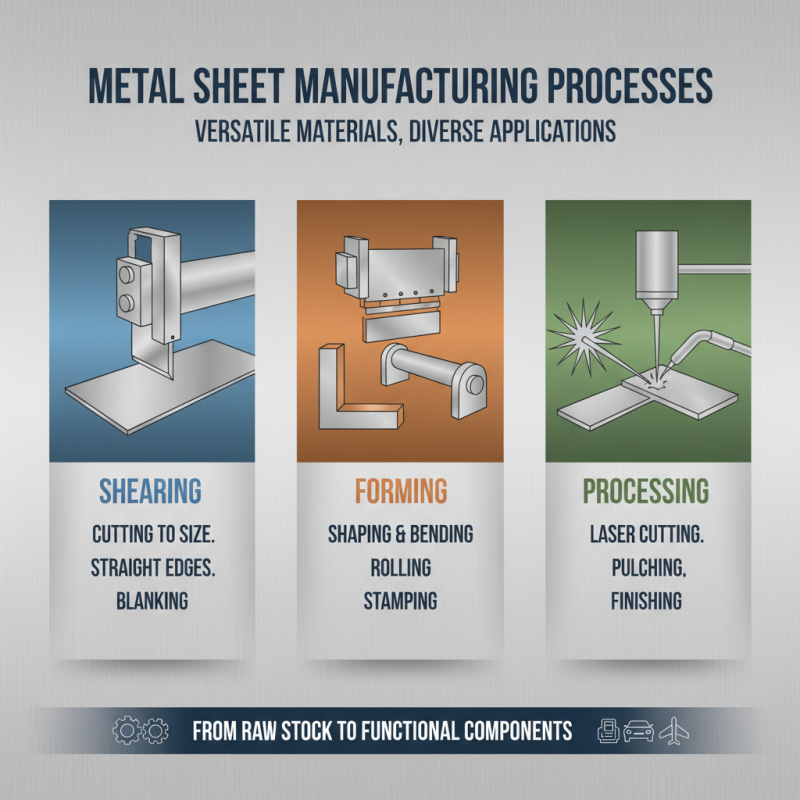

Metal sheets are versatile materials that undergo various manufacturing processes to achieve desired shapes and characteristics suitable for multiple applications across different industries. The primary methods used in the production of metal sheets include shearing, forming, and processing techniques, which transform raw metal stock into functional components.

Shearing is one of the initial steps in metal sheet manufacturing, where large metal plates are cut into smaller sheets. This process ensures precision and accuracy in dimensions, allowing for easier handling and further processing. Forming processes, such as bending and stamping, come next, enabling the sheets to be shaped into specific designs or configurations. These techniques are critical in industries like automotive, where metal sheets are often shaped to create body panels and structural components.

Further refinement of metal sheets occurs through processes like welding, machining, and surface treatment. Welding joins multiple sheets to create complex structures, while machining adds intricate details. Surface treatments, including painting or coating, enhance durability and aesthetics. Together, these manufacturing processes ensure that metal sheets are tailored to meet the specific needs of various applications, from construction to consumer products, highlighting their indispensable role in modern manufacturing.

Metal sheets are versatile materials used across various industries due to their strength, durability, and adaptability. In the automotive sector, metal sheets are essential for manufacturing body panels, structural components, and chassis parts. Their ability to be easily shaped and welded makes them ideal for producing lightweight yet sturdy vehicles, optimizing fuel efficiency while maintaining structural integrity.

In the construction industry, metal sheets play a crucial role in creating roofing, siding, and metal frameworks for buildings. They provide essential protection against weather elements, while also enhancing the aesthetic appeal of structures. Additionally, metal sheets are used in the fabrication of HVAC systems, ensuring efficient climate control in residential and commercial buildings. The versatility of metal sheets allows architects and builders to implement innovative designs that meet both functional and aesthetic requirements.

The electronics industry also relies heavily on metal sheets for manufacturing components such as casings and heat sinks. Their conductive properties make them suitable for applications that require efficient heat dissipation and electromagnetic shielding. In the packaging sector, metal sheets are often used to create durable containers and protective packaging solutions, ensuring product safety during storage and transportation. Overall, the diverse applications of metal sheets underscore their integral role in advancing technology and enhancing everyday life.

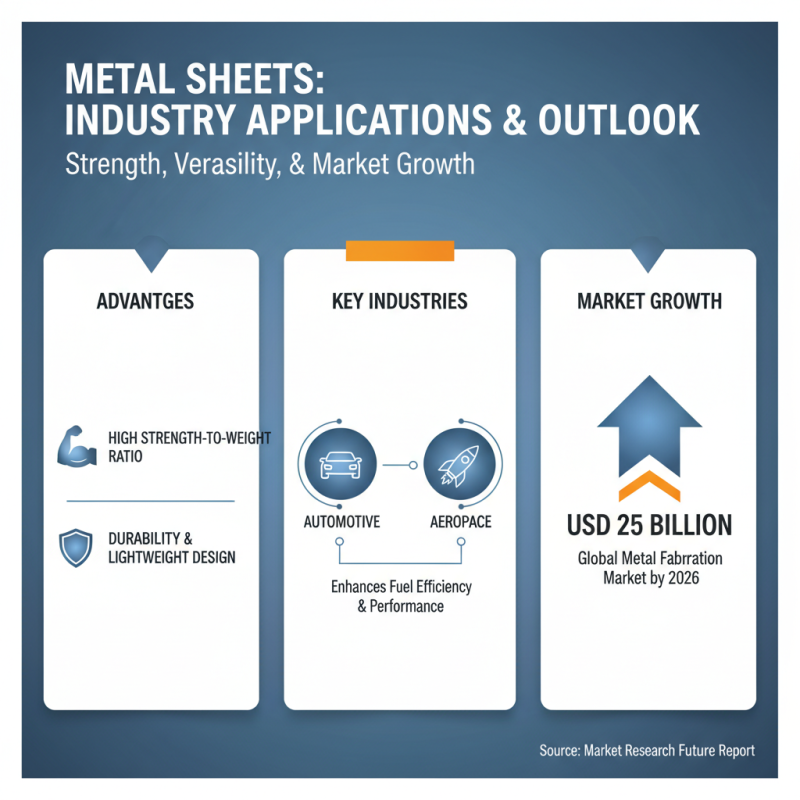

Metal sheets are widely utilized across various industries due to their unique properties, offering both advantages and disadvantages that impact decision-making in manufacturing processes. One of the primary advantages of metal sheets is their high strength-to-weight ratio, making them ideal for applications where durability is crucial without adding excessive weight. According to the Market Research Future report, the global metal fabrication market is expected to reach USD 25 billion by 2026, primarily driven by the demand in the automotive and aerospace industries. Metal sheets contribute to lightweight design criteria, enhancing fuel efficiency and performance in these sectors.

However, the utilization of metal sheets also comes with challenges. The cost of high-quality metal sheets can be significant, and their production often involves energy-intensive processes that may not be environmentally sustainable. A report by the International Energy Agency highlights that metal production accounts for approximately 7% of global greenhouse gas emissions, raising concerns about the ecological footprint of metal sheet usage. Furthermore, while metal sheets can be easily recycled, not all facilities prioritize recycling, which can lead to inefficiencies and waste. Balancing the economic benefits of metal sheets with their environmental impact is a key consideration for industries looking to adopt more sustainable practices.