In the world of metalworking, the term "Rolled Bar" holds significant importance. Industry expert John Smith, a leading metallurgist, emphasizes, "Rolled Bars are the backbone of structural integrity in construction." This statement reflects the essential roles these bars play in various applications.

Rolled Bars are commonly used in construction, automotive, and machinery industries. Their strength and durability make them a favorite among engineers. Smith notes that they provide a reliable solution for weight-bearing structures. This reliability is crucial; however, some challenges persist in production quality and consistency.

Understanding how Rolled Bars are made and utilized can lead to better applications. Techniques may vary, yet the goal remains similar: achieving optimal strength. Reflecting on the flaws in current processes can help industry players improve. The journey of these materials involves innovation, making it an ongoing exploration.

A rolled bar is a type of metal product that has undergone a specific manufacturing process, which involves rolling metal into a desired shape and size. Typically produced from steel or aluminum, these bars are vital in various industries, including construction and manufacturing. According to the World Steel Association, global steel production reached 1.87 billion metric tons in 2020, with a significant portion dedicated to rolled products.

Rolled bars come in various shapes, such as round, square, and hexagonal. Their applications are vast, ranging from creating structural components to manufacturing machine parts. The American Institute of Steel Construction estimates that nearly 90% of all structural steel in buildings is derived from rolled products. However, some users may overlook the importance of selecting the right type of rolled bar for their specific needs. Inadequate choices can lead to structural failures and increased costs.

Not all rolled bars are created equal. The quality and dimensions can vary significantly between manufacturers. This inconsistency can pose challenges for engineers and builders striving for precision. Reports indicate that discrepancies in rolled bar specifications can lead to a 15-20% increase in project timelines. It is crucial to reassess and scrutinize the quality standards in the procurement process. Ignoring this can have lasting implications on overall project efficiency and safety.

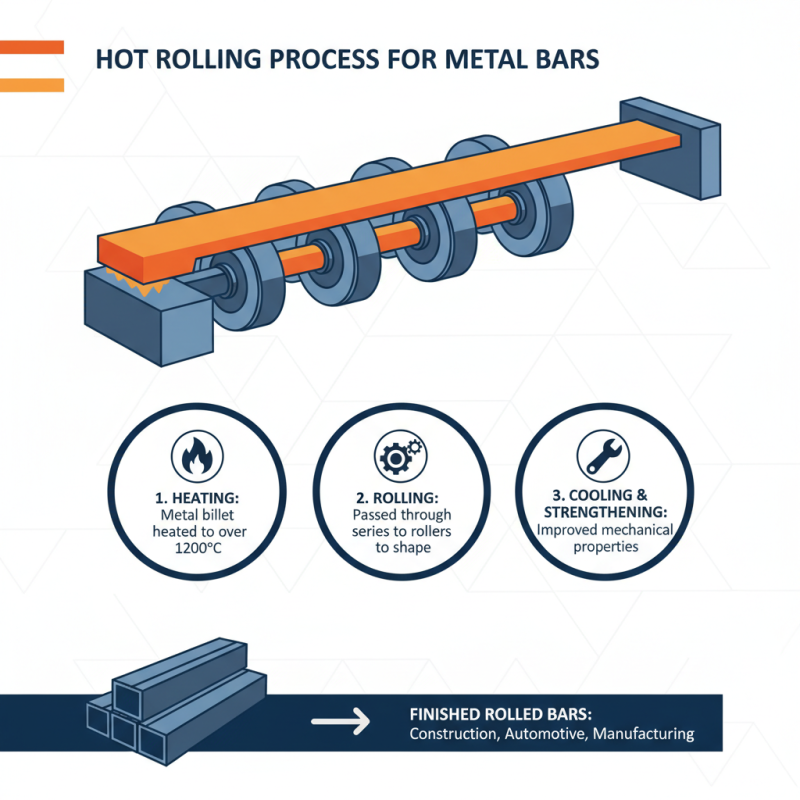

Rolled bars play a significant role in various industries. Their manufacturing process involves several techniques and materials. Typically, hot rolling is the most common method. In this process, metal billets are heated and then passed through rollers. This changes their shape while improving mechanical properties.

Cold rolling is another method. It refines the surface finish and can enhance strength. Cold-rolled bars are often used in applications where precision is critical. Materials for rolled bars include carbon steel, stainless steel, and alloy steel. Each type has unique properties that affect its suitability for different applications.

**Tip:** Always consider the material grade for your specific needs. Not all rolled bars are created equal.

The manufacturing process is not without challenges. For example, controlling the temperature during hot rolling is vital. If the temperature is too high or low, issues can arise. These challenges can affect both the quality of the bar and production efficiency.

**Tip:** Regular quality checks can help identify problems early. This proactive approach can save time and resources.

Rolled bars come in various shapes, each serving unique purposes in construction and manufacturing.

Round bars are among the most common types, often used for structural applications.

Data from the World Steel Association indicates that round bars account for nearly 30% of total rolled steel production.

Their circular cross-section allows them to withstand high-stress conditions effectively.

Square bars, on the other hand, offer versatility in fabrication.

They are frequently utilized in creating frames, brackets, and supports.

Their uniform edges allow for precise machining and welding, making them ideal for custom projects.

However, their rigidity can be a downside.

Special shapes, like hexagonal or flat bars, are also gaining traction.

They provide unique advantages in specific applications, such as automotive and aerospace industries.

Tip:

When selecting rolled bars, consider load requirements and environmental factors.

High tensile strength is crucial, but don’t overlook corrosion resistance.

Regular inspections are necessary to ensure material integrity over time.

Lastly, small imperfections in the bar can lead to significant issues during use.

Be vigilant in assessing quality before purchase.

Rolled bars are crucial in construction and engineering. They are versatile and serve many purposes. Builders often use them in structural frameworks and reinforcements. These bars provide strength and durability. They enhance the stability of buildings and bridges. Their application is evident in various types of projects.

In construction, rolled bars are used in roads and highways. They support the weight of heavy vehicles. They also play a role in creating steel frames for buildings. When combined with concrete, they improve overall durability. However, not all applications yield perfect results. Sometimes, issues arise during the welding process. Improper connections may weaken the structure over time.

Engineering fields utilize rolled bars in machinery and tools. They can be found in manufacturing equipment. Engineers favor them for their resistance to wear and tear. In automotive design, rolled bars provide essential support. But challenges exist, like corrosion. Regular inspections are necessary to maintain integrity. This highlights the ongoing need for advancements in material technology.

Rolled bars are important components in manufacturing and construction. Various industries rely on them for strength and durability. To ensure consistent quality, industry standards like ASTM and ISO play a crucial role. ASTM, or the American Society for Testing and Materials, develops specifications that define the properties of rolled bars. These include tensile strength and chemical composition.

ISO, the International Organization for Standardization, also sets guidelines. These standards promote uniformity across countries. Different grades and sizes of rolled bars are specified under these regulations. They ensure that materials perform well in their intended applications. Industries can use these specifications to guarantee the reliability of their products.

Adhering to these standards is essential, but it can be a challenge. Companies must stay updated on changing requirements. Quality control processes may require revisiting and refining. Some manufacturers overlook small details, leading to issues. This oversight can result in safety concerns and production delays. Organizations should continuously evaluate their practices to meet these standards effectively.