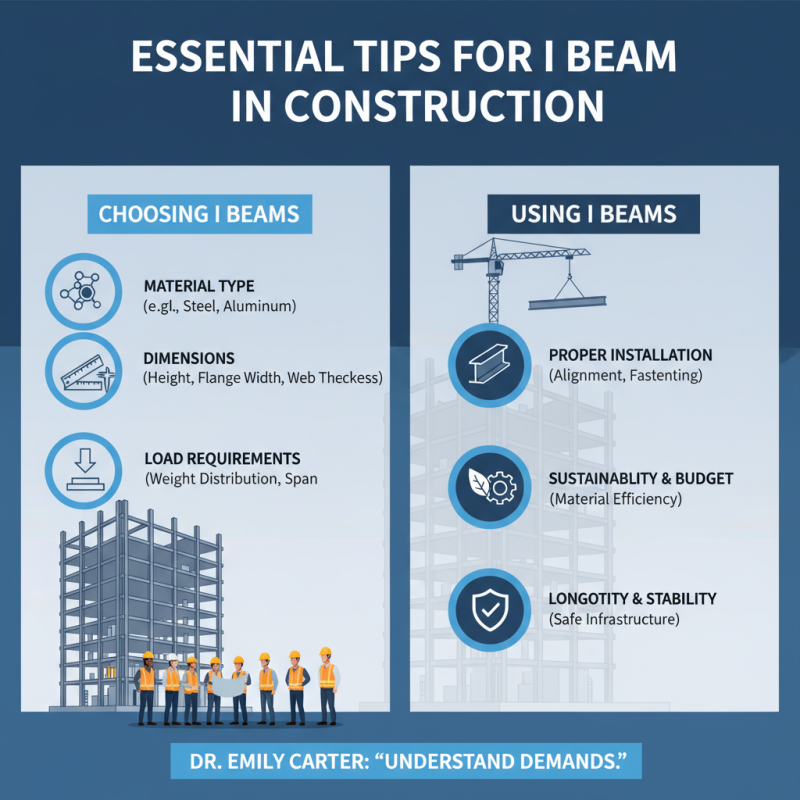

In the realm of construction, the selection and use of I Beams plays a pivotal role in ensuring the integrity and strength of structures. Renowned structural engineer Dr. Emily Carter emphasizes the significance of I Beams, stating, "Choosing the right I Beam is not merely a matter of preference; it’s about understanding the specific demands of your project." As construction projects continue to evolve, the importance of informed decision-making regarding materials cannot be overstated.

I Beams, with their distinctive shape and load-bearing capability, have become a staple in modern construction. Their ability to support substantial weights while maintaining material efficiency makes them essential in various applications, from residential buildings to towering skyscrapers. However, the process of selecting the appropriate I Beam involves a myriad of considerations, including material type, dimensions, and load requirements. Understanding these factors is crucial for architects and engineers aiming to deliver safe and durable structures.

Furthermore, the successful implementation of I Beams requires not only careful selection but also proper installation techniques. As the construction industry faces increasing challenges, including sustainability and budget constraints, the strategic use of I Beams can significantly impact project outcomes. By adhering to the best practices in choosing and utilizing I Beams, professionals can ensure the longevity and stability of their constructions, paving the way for safer infrastructures.

When selecting I beams for construction projects, several key factors must be considered to ensure structural integrity and efficiency. First, the load-bearing capacity of the I beam is critical. Assess the load conditions of the project, including both live and dead loads, to choose an appropriate size and grade of the beam. The dimensions and thickness of the web and flanges will directly influence strength and resistance to bending or buckling.

Additionally, material selection plays a pivotal role in the durability and longevity of I beams. Steel is a common choice due to its high strength-to-weight ratio, while aluminum can be suitable for lighter applications. Understanding the environmental conditions the construction will face, such as exposure to moisture or corrosion, can also guide the choice of materials and protective coatings.

Tip: When evaluating I beams, consider utilizing software or consulting with structural engineers to simulate load scenarios. This can help in making informed decisions that align with project specifications. Moreover, always check regulatory standards and best practices in beam selection to avoid costly errors in the future. Proper installation techniques and adherence to guidelines will further ensure that the selected I beams perform effectively throughout the life of the construction.

I beams, also known as universal beams, are crucial elements in construction, providing strength and stability to structures. When choosing an I beam, it's important to understand the different types available. The most common types include wide flange beams, which are versatile and suitable for various applications, and standard beams, which are typically used for lighter loads. Each type has unique design specifications that cater to specific construction needs.

Another important aspect is the material used in I beams. Steel is the most popular choice due to its high tensile strength and durability, making it an ideal option for heavy-duty constructions. However, aluminum I beams are also available for applications requiring lighter weight and resistance to corrosion. Understanding these options allows builders to select the right kind of I beam that fits both structural requirements and environmental conditions, ensuring the safety and longevity of the construction project.

I beams, also known as universal beams or H beams, are a popular choice in structural applications due to their exceptional strength-to-weight ratio. This design, characterized by a central web and flanges at the top and bottom, allows for efficient load-bearing capabilities while minimizing the amount of material used. By effectively distributing loads, I beams can support larger spans compared to traditional beam types, making them ideal for a variety of construction projects, from residential buildings to large industrial facilities.

One of the key benefits of using I beams is their versatility. They can be employed in a variety of structural applications, including columns, beams, and trusses. This adaptability means that they can be tailored to fit the specific requirements of a project, whether that involves accommodating heavy loads in a commercial building or providing support in a residential home. Furthermore, the durability of I beams ensures that structures remain stable and secure over time, reducing maintenance costs and enhancing overall safety. Their resistance to buckling and bending under pressure adds to their effectiveness, making them a reliable choice for engineers and construction professionals alike.

When installing I beams in construction projects, proper techniques are essential to ensure structural integrity and safety. First, it is crucial to understand the load requirements and the specific application of the I beam. Begin by preparing the site and ensuring that all necessary tools and equipment are on hand. Accurate measurements should be taken during the installation process, as miscalculations can lead to serious issues later. Additionally, beams should be level and securely fixed to prevent any shifting or damage over time.

Regular maintenance of I beams is equally important to extend their lifespan and performance. Inspect beams periodically for signs of corrosion, cracks, or deformities. Make sure that the connections, such as welds and bolts, are intact. If any damage is detected, addressing it promptly can prevent more significant structural failures. Furthermore, it’s essential to keep beams free from excessive moisture and debris that could lead to rust or other deterioration. By following these guidelines for installation and maintenance, construction projects can achieve optimal stability and safety with I beams.

This chart illustrates the common uses of I Beams in various construction applications, highlighting their prevalence and importance in structural integrity.

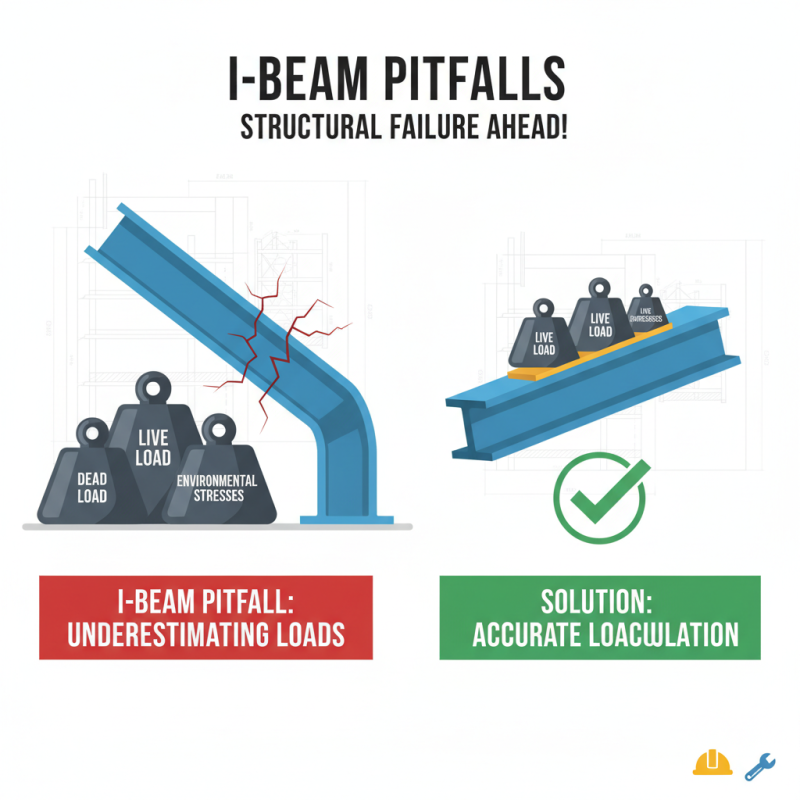

When working with I beams in construction, it is crucial to avoid common pitfalls that can lead to structural issues or project delays. One of the most frequent mistakes is underestimating the load requirements. It is essential to accurately calculate the loads that the I beams will need to support, including dead loads, live loads, and any additional stresses from environmental factors. Failing to do so may result in using beams that are insufficiently strong, risking structural failure.

Another common error is neglecting proper connections. The strength of I beams relies not just on their material but also on how they are integrated into the structure. Poorly designed connections can compromise stability and load distribution. It's vital to ensure that connections are made using appropriate methods, whether welding, bolting, or a combination of both, and that they comply with industry standards.

Additionally, overlooking maintenance considerations can lead to long-term problems. Even high-quality I beams can suffer from corrosion or fatigue over time, especially in environments with adverse conditions. Implementing a regular inspection and maintenance routine is essential to ensure the longevity of the structure and the safety of those who use it. By being aware of these common mistakes and taking proactive steps, construction professionals can effectively limit risks and enhance the durability of their projects.