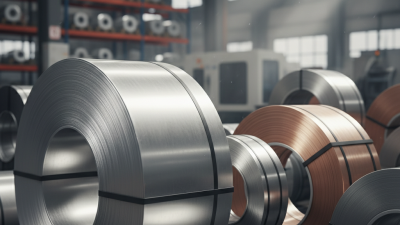

Choosing the right metal coil for your project can be a daunting task. Various factors come into play when making this decision. Metal coils differ in material, thickness, and intended application. Each project demands a unique approach to selection.

Start by considering the type of metal you need. Stainless steel, aluminum, and copper all have distinct properties. Your project’s demands can dictate the best option. Weighing these factors helps ensure durability and effectiveness. Precision in choosing your metal coil is crucial for the final outcome.

It might seem simple, yet many overlook critical details. For instance, the coil's gauge can significantly impact the strength and flexibility of your work. Always measure twice and verify specifications. Remember, the wrong choice could lead to costly adjustments later on. Reflecting on these aspects is vital in achieving satisfactory results.

When choosing the right metal coil for your project, understanding the different types available is crucial. Metal coils are categorized into various types based on their material and properties. For example, steel coils are known for their strength and durability. They are ideal for construction and automotive applications. According to industry reports, over 50% of metal coils used in manufacturing are made of steel.

Aluminum coils are another popular option. They are lightweight and corrosion-resistant, making them suitable for a variety of applications. The global aluminum coil market is projected to grow by 4% annually, driven by increasing demand in the aerospace and automotive sectors. However, the choice of aluminum may not be suitable for projects requiring high tensile strength.

Copper coils are often used for electrical wiring due to their excellent conductivity. Yet, they are more expensive than other materials. Projects may sometimes face budget constraints, making it essential to weigh the benefits against costs. This decision can be tricky. Each type of metal coil has its advantages and limitations. Knowing these details aids in making an informed choice for your project.

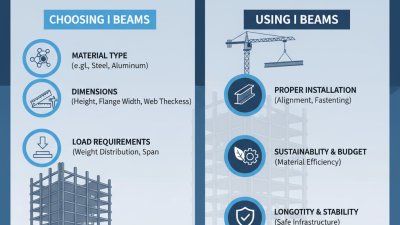

Choosing the right metal coil for your project involves several key factors. You need to consider the type of metal, thickness, and finish. According to industry reports, aluminum and stainless steel coils are the most popular choices. They offer durability and resistance to corrosion. Aluminum coils are lighter, which can reduce shipping costs. However, they might not be suitable for every application.

When selecting a metal coil, thickness plays a vital role. Standard gauges vary and can affect the strength of your final product. A thinner coil may save costs, but it could compromise durability. A recent study suggested that 60% of production issues stem from incorrect gauge selection. This is a significant loss that could have been avoided.

It's wise to request samples before making any large orders. This allows you to test the material for your specific application. Additionally, consider the finish. A polished finish can provide aesthetic appeal but might require additional processing time. Remember that every project has unique requirements. Balancing cost with quality is essential, but don't overlook the fine details. They often make all the difference in your project's success.

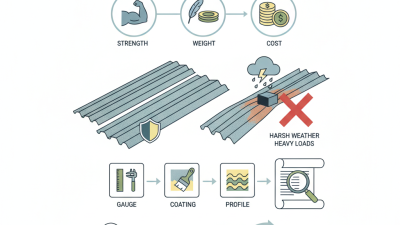

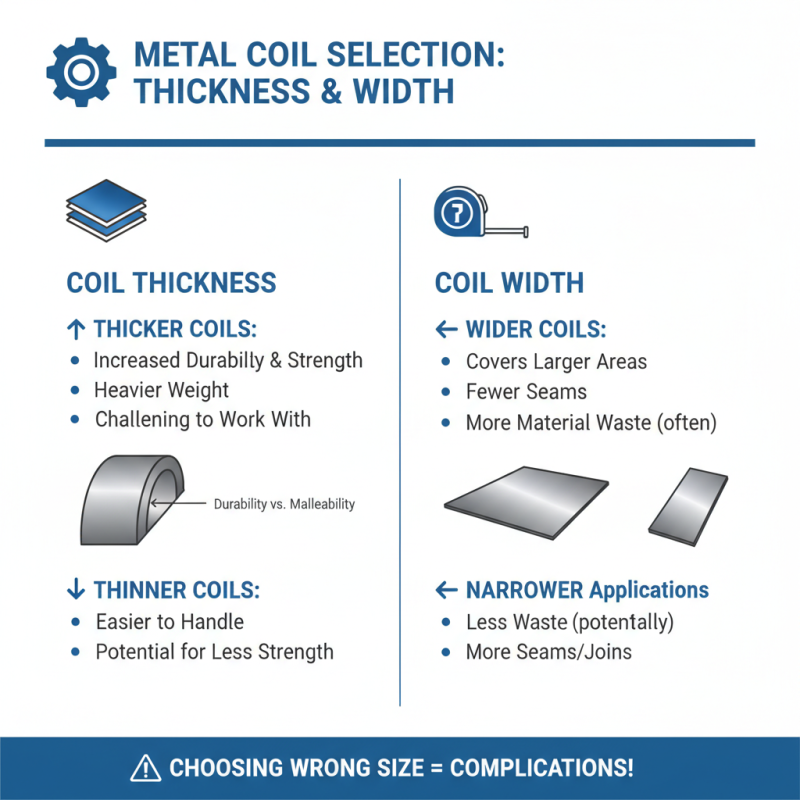

When selecting the right metal coil for a project, coil thickness and width are vital factors. The thickness of the coil can affect durability and weight. Thicker coils may offer better strength. However, they can also be harder to work with. Choosing the wrong thickness can lead to unnecessary complications.

Width is equally important. It determines how much material you have to work with. A wider coil provides more coverage but can waste resources if not utilized properly. If it's too narrow, it may not serve the purpose. Often, finding the perfect balance is essential.

Here are some tips: Test different thicknesses with smaller projects first. It allows you to gauge their performance. Also, visualize the final use. Consider how the width will impact your overall design. Always factor in potential mistakes when calculating your needs. This will save time and money later.

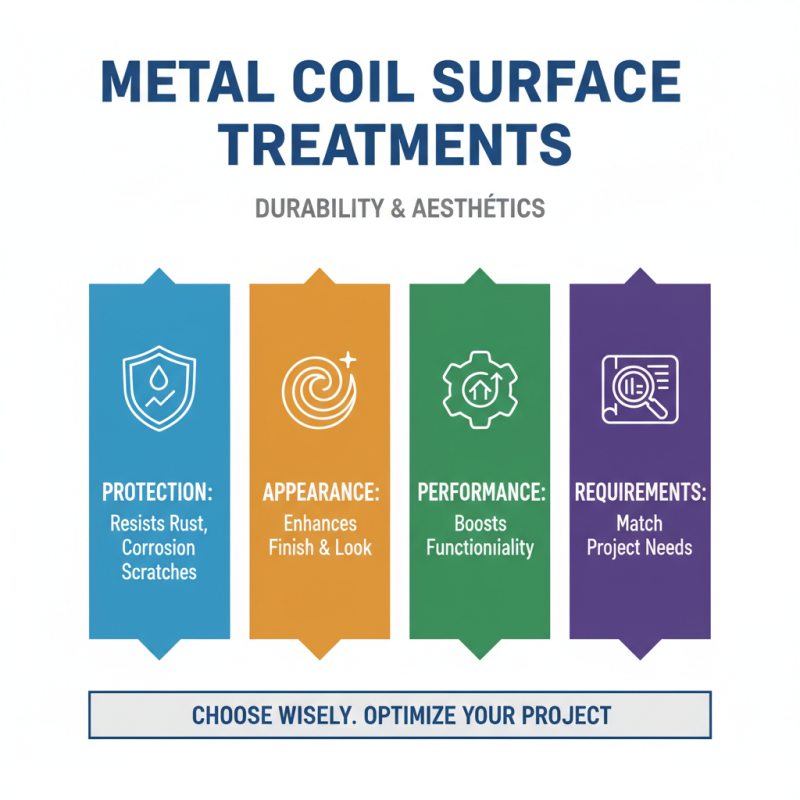

When selecting metal coils for your project, surface treatments are crucial. They can greatly influence durability and aesthetics. Different finishes help protect against rust, corrosion, and scratches. Some coatings improve appearance while others enhance performance. It’s essential to understand your project requirements before deciding on the right finish.

For example, anodizing can create a protective layer on aluminum. This process improves corrosion resistance. However, it may not be suitable for all applications. Similarly, powder coating offers a robust finish, but color options may be limited. If your project requires a specific look, this could be a setback.

Moreover, some treatments may not adhere well to every metal type. Be cautious in your selection. Do tests if necessary. Adjusting your choice based on real-world performance is critical. Consider the trade-offs between aesthetics and functional requirements. Each surface finish has its strengths and weaknesses. Understanding them is key to ensuring a successful outcome for your project.

When selecting metal coils for your project, cost is a vital factor. Prices can vary widely among different suppliers. Understanding your budget constraints can help narrow down choices. Bulk ordering may lower costs, but it requires careful planning. Think about your project's timeline. Sometimes, the cheapest option isn’t the best choice.

Sourcing strategies are equally important. Researching local vendors can save on shipping costs. Some suppliers offer discounts for new customers. Don’t overlook online platforms, as they can provide competitive pricing. However, ensure quality control. Samples can be critical to gauge the material's suitability.

Be open about your needs. Communication with suppliers can lead to better deals. Be prepared for some negotiation. Reflect on your priorities—cost versus quality. This could impact your long-term satisfaction with the project.