The construction industry is increasingly turning to innovative Metal Girder designs to enhance efficiency and safety. Dr. Jane Smith, a leading expert in structural engineering, notes, "Metal Girders are transforming how we think about strength and sustainability." As we move towards 2026, these advancements promise to reshape our skylines and infrastructure.

Metal Girders are not just about material quality; they represent a shift in construction philosophy. Builders are embracing lightweight designs that do not compromise on strength. However, challenges remain. Some designs may not account for environmental impacts effectively. Engineers must find a balance between innovation and sustainability, ensuring that progress does not come at a cost.

In today's rapidly evolving construction landscape, awareness of these trends is crucial. The integration of smart technologies into Metal Girders is becoming more common. Yet, this raises questions about reliability and safety. Stakeholders must reflect on these aspects as they adopt new methods and materials. The future of Metal Girders is bright, but not without its hurdles.

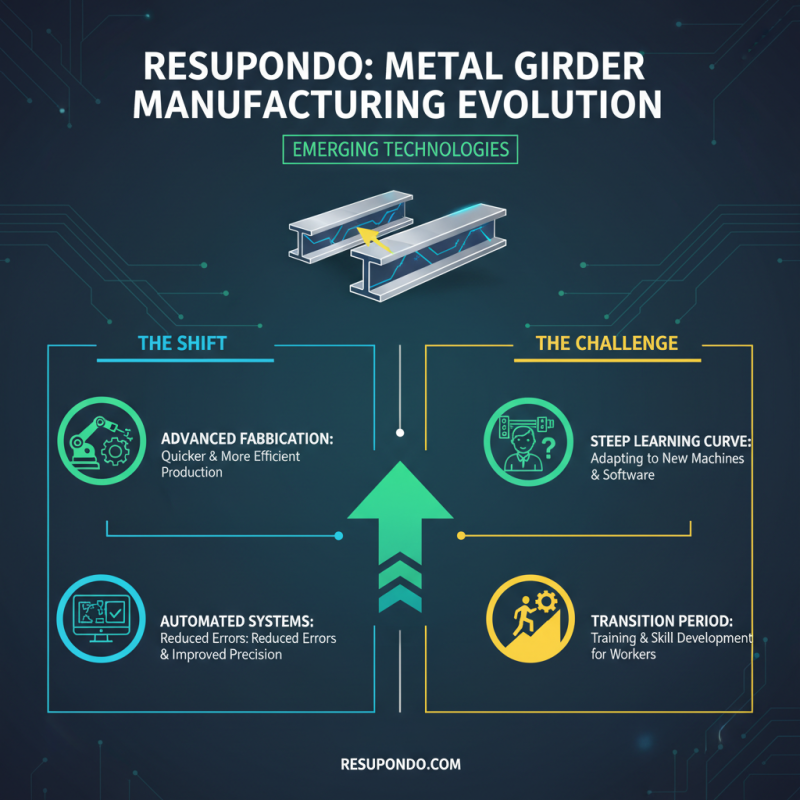

Emerging technologies are reshaping metal girder manufacturing. Advanced fabrication methods are making production quicker and more efficient. Automated systems are reducing errors and improving precision. However, these innovations often come with a steep learning curve. Workers must adapt to new machines and software. This transition can be challenging.

3D printing and generative design are gaining traction. These methods allow for complex shapes that traditional methods struggle to create. They can decrease material waste and enhance strength. But they require high initial investment. Some companies hesitate to move forward due to this cost.

Sustainability is another focal point. Recyclable materials are increasingly used in production. This shift helps reduce the environmental footprint. Still, the adoption rate varies across the industry. Many firms are stuck using outdated practices despite the potential benefits. It's clear that the future of metal girder manufacturing is promising, yet complex.

The construction industry is increasingly focusing on sustainable materials. Metal girders, commonly used in infrastructure, also evolve to meet these demands. A recent report from the International Energy Agency indicates that the construction sector contributes nearly 40% of global carbon emissions. Thus, adopting greener practices is essential.

Recycled steel is gaining traction. It reduces both waste and energy consumption. According to industry research, using recycled steel can lower energy use by up to 75%. Furthermore, metal girders have a long lifespan, lasting over 50 years. This durability translates to less frequent replacements, which further lessens environmental impact.

However, challenges remain. The energy-intensive processes of steel production raise concerns. Many companies are exploring greener production techniques, yet their effectiveness varies widely. The industry must reflect on balancing performance with sustainability. Choosing the right materials is not just a trend; it’s a necessity in our fight against climate change.

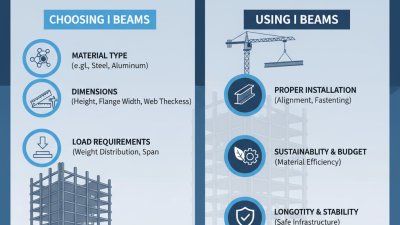

Innovative design techniques in metal girder construction are paving the way for enhanced structural integrity. Recent industry data indicates that the global metal girders market is expected to grow by 5.4% annually. This trend is attributed to the increasing demand for stronger, more durable structures. Engineers are now focusing on advanced materials like high-performance steel. These materials resist environmental challenges better than traditional options.

In 2026, the emphasis on sustainability is likely to drive innovations in design. For instance, utilizing optimized geometries can significantly reduce material usage while maintaining strength. Computer-aided design software enables precise simulations, ensuring that designers can predict performance under load. However, many projects still face challenges in implementation. A considerable number fail to integrate new techniques effectively, resulting in structural weaknesses.

It’s essential to recognize that further research is needed. Studies show that only 30% of construction firms fully adopt innovative practices. Many struggle with cost constraints and lack of training. This gap highlights the importance of continuous education in the industry. As construction practices evolve, collaboration among engineers, architects, and builders will be critical to maximizing the benefits of new design methodologies.

| Dimension | Trend | Description | Impact |

|---|---|---|---|

| Weight Reduction | Advanced Materials | Use of high-strength steel alloys to reduce girder weight. | Improved load capacity and reduced material costs. |

| Corrosion Resistance | Coating Technologies | Innovative coatings that enhance durability and resistance to elements. | Extended lifespan and reduced maintenance costs. |

| Sustainability | Recyclable Materials | Incorporation of recyclable materials in construction processes. | Minimized environmental impact and enhanced industry standards. |

| Design Flexibility | Modular Construction | Utilization of modular components for ease of assembly. | Faster construction times and reduced labor costs. |

| Load Distribution | Optimization Algorithms | Use of software tools to design girders with optimal load distributions. | Enhanced structural integrity and performance. |

The construction industry is witnessing a significant shift towards automation and robotics, particularly in metal girder construction. Drones survey sites with precision. Robotic arms perform repetitive tasks, increasing efficiency while minimizing human error. This shift allows for better resource allocation on the construction site. Workers can focus on more complex tasks that require problem-solving.

However, embracing these technologies isn't without challenges. There’s a steep learning curve for workers. Training programs need to be robust and effective. Additionally, the initial investment can be daunting for smaller firms. Some might hesitate to adopt these innovations due to cost concerns.

Despite these obstacles, the potential benefits are substantial. Automated processes improve safety by handling heavy loads. Robots can work in environments deemed hazardous for humans. As companies adapt, we will see how automation shapes the future of metal girder construction. Still, the path to full integration demands careful planning and reflection on human-robot collaboration.

Smart metal girders are reshaping construction. They integrate IoT technology, offering advanced solutions. These innovations promise real-time data collection and analysis. Sensors embedded in the girders monitor structural health. This enhances safety and reduces maintenance costs.

Tips: Consider the importance of connectivity. Each girder needs to communicate seamlessly. Ensure your team is trained to manage this technology effectively.

Building with smart girders also poses challenges. Data overload can be an issue. Teams must prioritize key metrics. Finding balance is essential for success. Clear communication among stakeholders is crucial. Setting realistic expectations will help the process.