In recent years, the construction industry has seen a significant shift towards the use of metal girders. These structural components provide necessary support and stability in various projects. According to a report from the American Institute of Steel Construction, over 90% of large commercial buildings now incorporate metal girders due to their strength and durability.

Metal girders are favored for their ability to span longer distances, reducing the need for numerous columns. This characteristic not only optimizes space but also allows for more flexible design options. Moreover, with the increasing demand for sustainable practices, metal girders are often recycled, aligning with green building initiatives. Yet, challenges remain. The installation process can be complex, and miscalculations in design can lead to structural issues.

Many engineers express concerns about the long-term performance of metal girders under extreme conditions. There’s a need for ongoing research and improvement in material quality and installation techniques. Discussions within the industry highlight both the advantages and potential pitfalls of relying heavily on metal girders. A nuanced understanding is essential for their optimal use in construction.

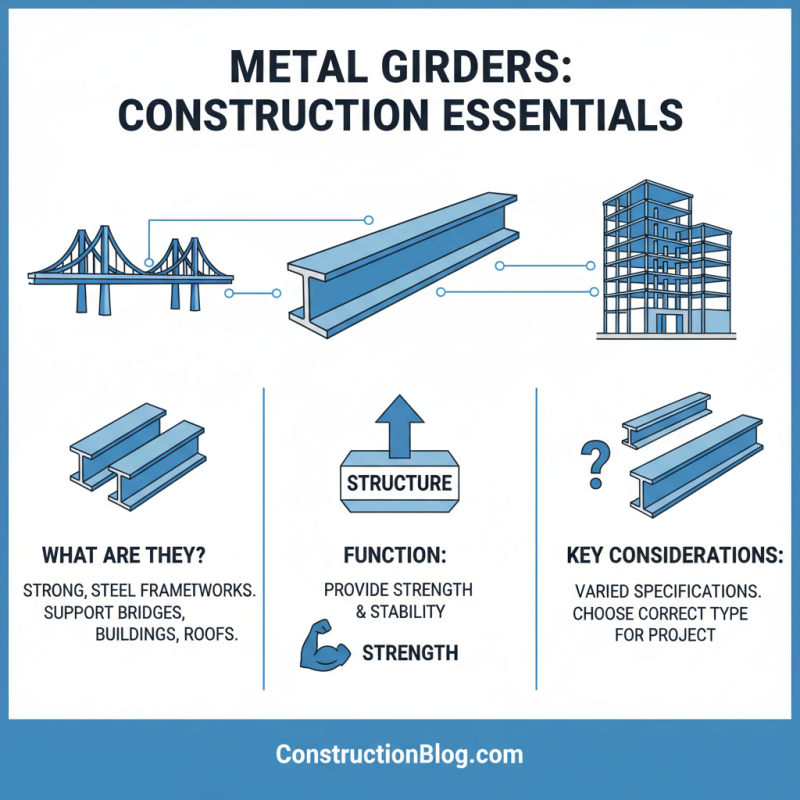

Understanding metal girders is essential for any construction project. These strong, steel frameworks are vital for supporting structures like bridges, buildings, and large roofs. They provide the necessary strength and stability. Specifications can vary widely, though. It's crucial to know what type suits your project best.

When choosing metal girders, consider their load-bearing capacity. A mismatch can lead to structural failures. Inspection and maintenance play key roles in longevity. Regularly check for rust or deformation. These small issues can escalate if ignored.

Tips: Always consult a structural engineer when selecting girders. Their expertise ensures safety and compliance with local regulations. Use quality materials and double-check measurements. A mistake here can be costly. Investing in good design upfront saves time later.

Metal girders play a vital role in modern construction projects. They provide structural support and stability. Various types of metal girders, including I-beams, T-beams, and box girders, are commonly used. According to industry reports, 50% of construction projects now feature steel girders due to their strength and durability.

I-beams are the most popular choice, making up 40% of metal girder usage. They offer great load-bearing capacity. T-beams, which combine a flange with a web, can efficiently support larger spans. Box girders are preferred for bridges. They are extremely rigid and can withstand heavy loads.

While metal girders are effective, they require careful handling. Corrosion can be a significant issue. Proper coatings and treatments are essential. Sometimes, structural calculations may overlook real-world conditions. This can lead to unexpected failures. Ultimately, understanding the types and properties of metal girders is crucial. It ensures that construction projects are safe and reliable.

This chart illustrates the percentage usage of various types of metal girders in construction projects for the year 2026. Steel girders dominate the market, comprising 55% of usage, while aluminum and composite materials follow with 20% and 15% respectively. Reinforced and pre-stressed girders make up the remaining 10%.

Metal girders serve as vital components in many construction projects. Their load-bearing capacity remains a crucial consideration. According to a report by the American Institute of Steel Construction, properly designed metal girders can support loads exceeding 50,000 pounds. This makes them ideal for both commercial and industrial applications.

When analyzing structural integrity, engineers focus on material properties and load distribution. A study from the Journal of Constructional Steel Research highlights that steel's yield strength can significantly impact the girder's performance under stress. These girders must resist bending and shear forces while maintaining stability. However, calculations can sometimes overlook localized stresses, leading to potential failure points.

Real-world examples demonstrate the importance of thorough structural analysis. In 2019, a bridge collapse in Florida was partially attributed to inadequate load assessments of the girders. Projects must incorporate advanced design techniques and finite element analysis to avoid such failures. Inspecting and reinforcing girders only after an initial assessment can result in costly repairs and delays.

When installing metal girders, precision and safety are paramount. According to a report by the National Institute of Standards and Technology, improper installation can lead to critical failures. Girders must be aligned correctly. A misalignment of even a few millimeters can compromise structural integrity. Use laser technology for accurate positioning. This can minimize errors and ensure a safer build.

Another important aspect is the selection of materials. Research shows that the type of steel used in girders can influence longevity. High-strength low-alloy steels are increasingly preferred for their durability. They provide better performance under stress. However, the cost can be higher. Project managers need to weigh the benefits against budget constraints. Investing in quality can save money in the long run.

Training workers is often overlooked. Many projects lack sufficient training sessions on girder installation. About 30% of construction delays are tied to inadequate worker skills, according to a 2022 study. Regular workshops can significantly reduce mistakes. Engaging in hands-on training promotes a safer work environment. Girders are critical components. Their proper installation is essential for structural success. Addressing these issues can improve project outcomes significantly.

When it comes to using metal girders in construction, safety is paramount. Construction sites are alive with activity. Workers, machinery, and materials all come together, creating a complex environment. Adhering to safety standards can make the difference between a project’s success and safety hazards. Metal girders must be inspected regularly. Any sign of corrosion or damage can lead to severe consequences. Reinforcement where needed can ensure longevity and stability.

Proper training is essential for workers handling metal girders. They should know how to lift and position these heavy elements safely. Personal protective equipment must be used at all times. Eye protection, gloves, and hard hats cannot be overlooked. Even minor oversights can lead to injuries, impacting everyone on site. Regulations dictate that clear signage should mark hazardous areas. This is often neglected, despite its importance in maintaining a safe working environment.

Visibility of load limits on equipment is crucial. Workers must understand their capabilities and limitations. Misjudgments can lead to accidents, causing delays and increased costs. Every project is unique. Therefore, adapting safety protocols to fit specific conditions is necessary. Regular safety meetings can help reinforce the importance of these standards. Learning from past mistakes can lead to overall improvements in safety culture.

| Aspect | Details |

|---|---|

| Material Types | Steel, Aluminum, Composite Materials |

| Load Capacity | Generally ranges from 1000 lbs to over 500,000 lbs depending on design |

| Common Applications | Bridges, Buildings, Industrial Sites, Renovation Projects |

| Safety Standards | OSHA regulations, AISC standards, Local building codes |

| Installation Requirements | Proper lifting equipment, secured anchoring, and skilled labor |

| Inspection Frequency | Before installation, after major loads, and annually |

| Environmental Considerations | Corrosion resistance, heat treatments, and recycle options |

| Training for Workers | Rigging, safety protocols, and hazard recognition |