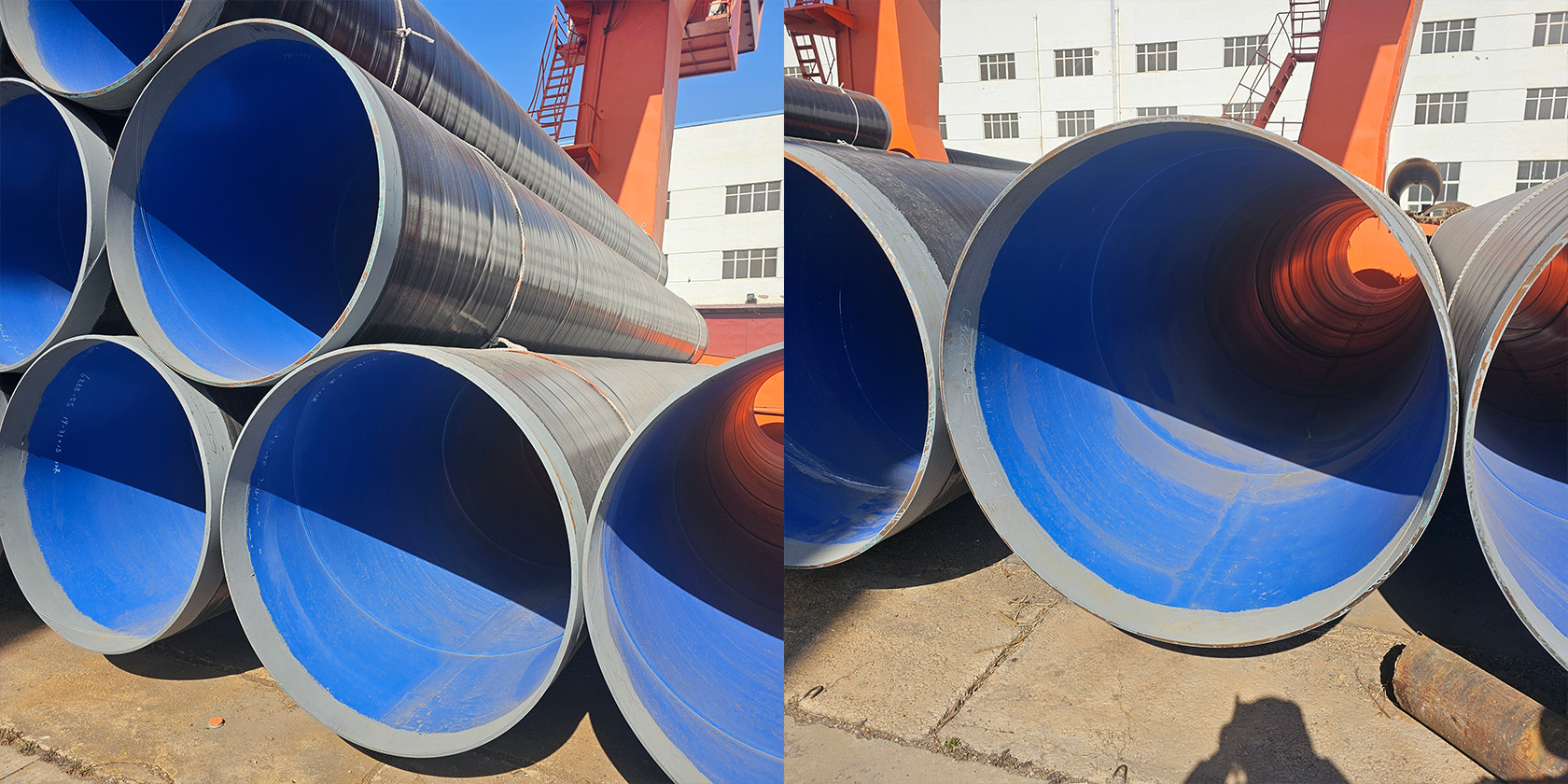

Factory Supply Customized Spiral Welded Steel Pipe

description1

Production description

Product Name |

Spiral pipe |

Outer DIA |

219mm-3000mm or according to customer's requirement |

Length |

6-12m or according To Customer's Demends |

Thickness |

5mm-28mm or according to customer's requirement |

Grade |

Q235B,Q355B |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

MOQ |

5 tons |

Production process

Raw Material Preparation

Select high-quality steel strips, conduct material inspection, and uncoil them for further processing.

Production Process

Forming

Feed steel strips into the forming machine, which gradually bends and shapes them into a spiral tube through a series of rollers.

Production Process

Welding

Employ automatic welding equipment to continuously weld the edges of the spiral tube, ensuring a strong and seamless joint.

Production Process

Calibration and Straightening

Adjust the diameter and shape of the welded pipe to meet specified standards, and straighten it to eliminate any curvature.

Production Process

Cutting

Cut the continuous pipe into required lengths according to project needs.

Production Process

Quality Inspection

Carry out strict inspections, including non-destructive testing, dimensional measurement, and pressure testing, to ensure compliance with international quality standards.

Production Process

Surface Treatment

Apply anti-corrosion coatings or other surface treatments to enhance the pipe’s durability and performance.

Production Application

Footwear abrasion solutions

1. Petroleum and Natural Gas: Used for long-distance transmission trunk lines and offshore platforms. With high strength and pressure resistance, it ensures transportation safety and can withstand complex marine environments.

2. Municipal Engineering: Serves as the main pipeline for urban water supply, meeting the demand for large-diameter water transportation. Applied to drainage and sewage networks, its smooth inner wall prevents blockages, and corrosion resistance extends its service life.

3. Energy and Power: For cooling water transportation in nuclear power plants and thermal power plants, it can withstand high temperature, high pressure, and large - flow water. As cable protection sleeves inside wind turbine towers, it provides mechanical protection

4. Industrial Field: Transports corrosive media in chemical enterprises, ensuring safety with anti-corrosion coatings. Used as power pipelines in factories to achieve stable and efficient transmission.

5. Transportation: Used as bridge pile foundations and support structures, bearing loads with high strength. Applied as ventilation and drainage pipelines in tunnels to meet the requirements of special environments.