High-Quality Hot Rolled I-beam Now Available for Sale

description1

Production description

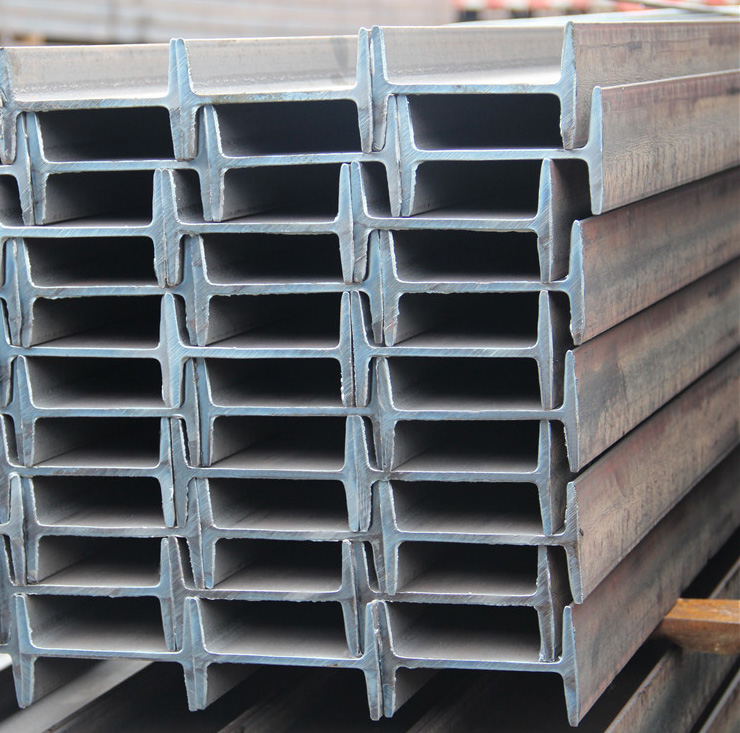

Product name |

I beam/Universal Beam |

Web height |

100-630mm or customize according to customer requirements |

Web Thickness |

4.5-17mm or customize according to customer requirements |

Flange width |

68-180mm or customize according to customer requirements |

Each weight |

5-50kgs or as customer requirements |

Grade |

S235JR,S275JR,S355JR,SS400,A36 |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Technique |

hot rolled |

MOQ |

5 tons |

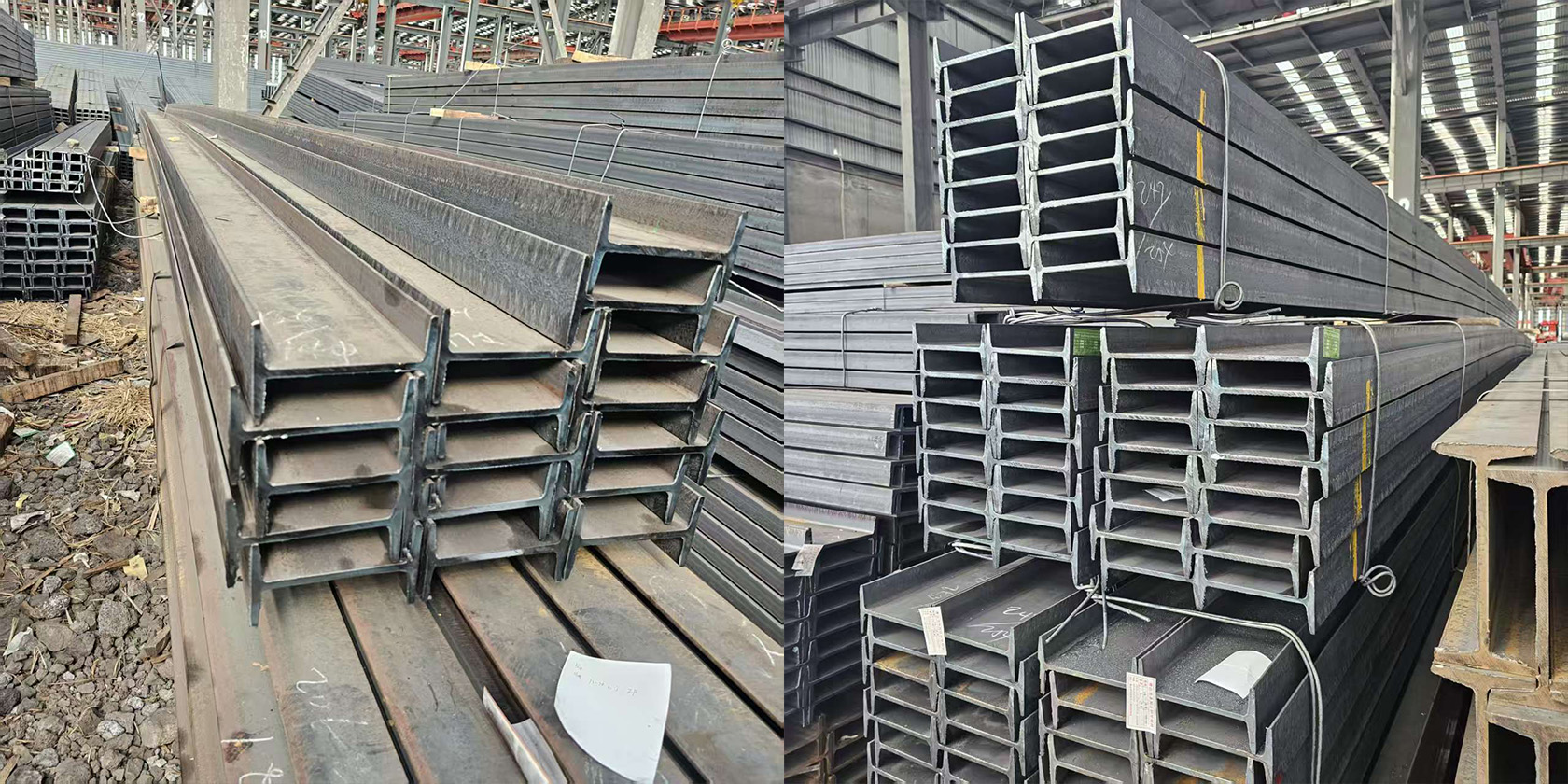

Production process

Raw Material Preparation

Select high-quality continuous casting billets or blooming billets, and control the composition, dimensions, shape, etc.

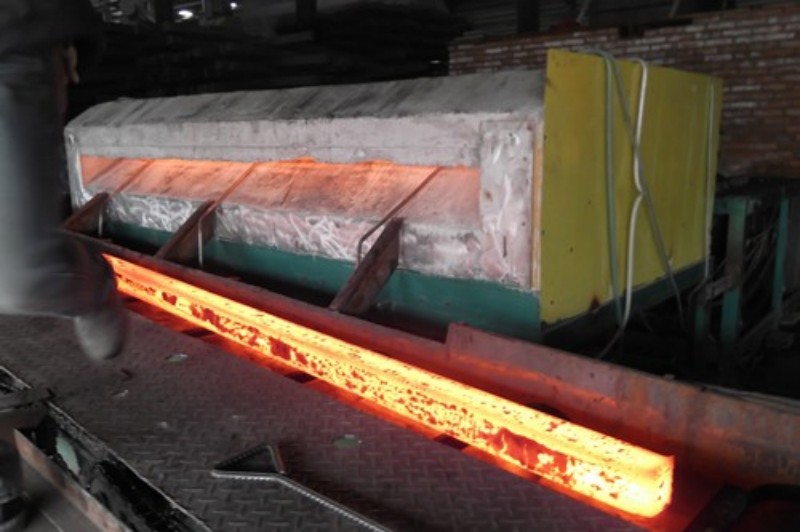

Production Process

Heating

Heat the billets in a heating furnace to a temperature range of 1100 - 1250°C.

Production Process

Rolling

Through rough rolling and finish rolling processes, shape the billets into the I-beam form.

Production Process

Cooling

After water cooling or air cooling, straighten the I-beams and grind away any defects.

Production Process

Straightening

After the performance inspection meets the standards, mark and package the I-beams for delivery.

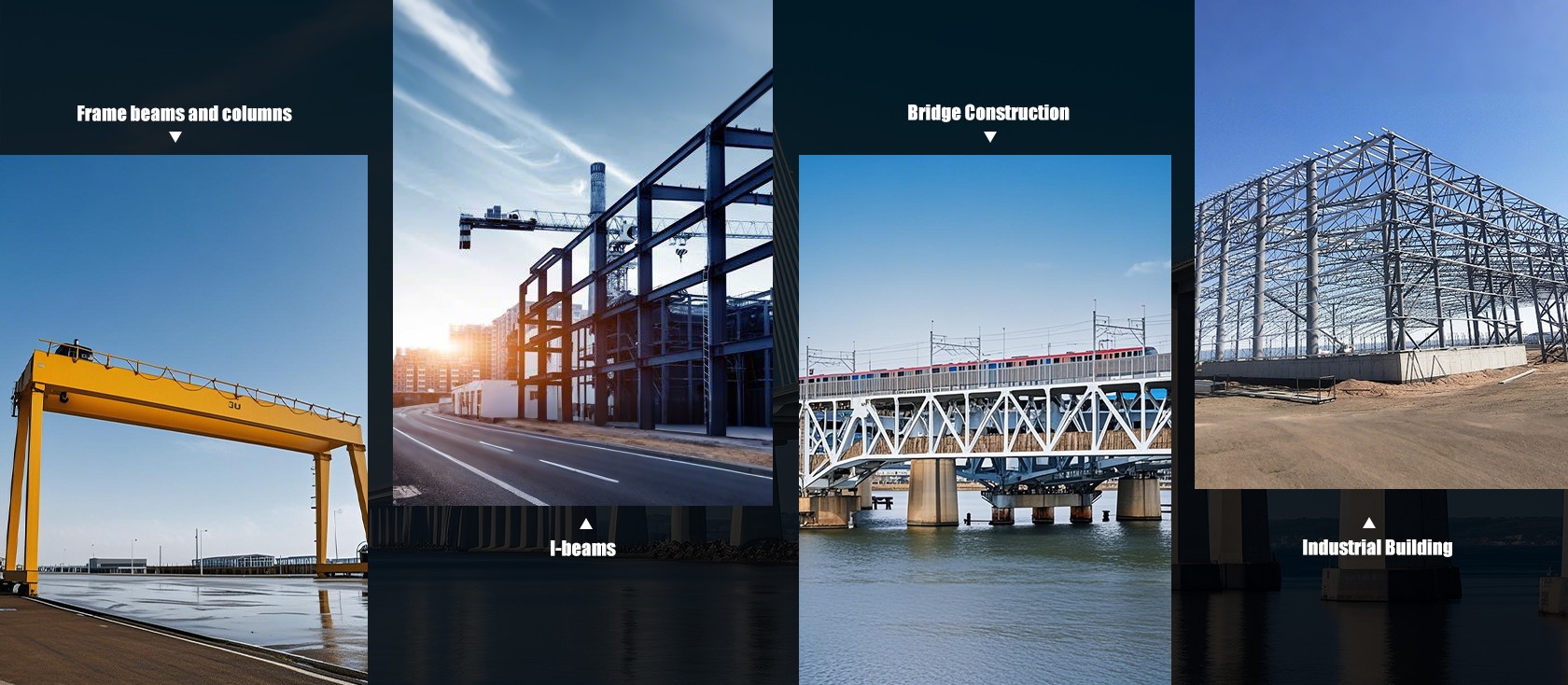

Production Application

Footwear abrasion solutions

1. Construction Engineering: Used to construct the frame beams and columns of industrial and civil buildings, bearing vertical and horizontal loads.

2. Bridge Construction: Applied to key parts such as bridge main girders and piers, withstanding traffic and natural loads.

3. Mechanical Manufacturing: Fabricate key components like machine tool beds and the main girders of lifting equipment to ensure the operational stability of the equipment.

4. Other uses: In mining tunnels, I-beams are mainly used to make support brackets to ensure stable working space. In the power industry, I-beams are also used to construct iron towers for high-voltage transmission lines.