Hot sell Q235 Q355 steel beam I-Beams for Steel Structure

description1

Production description

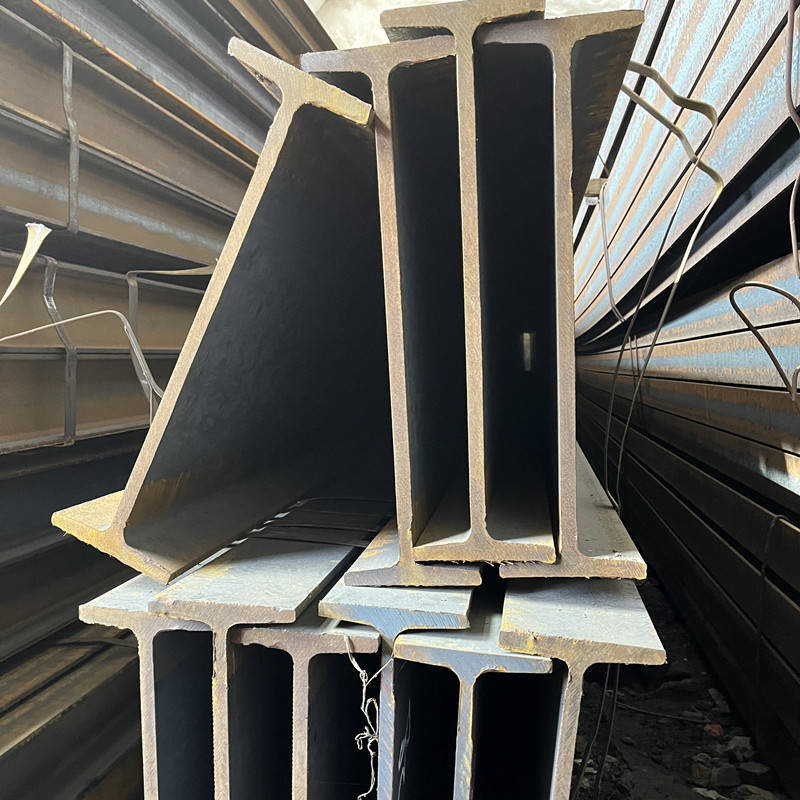

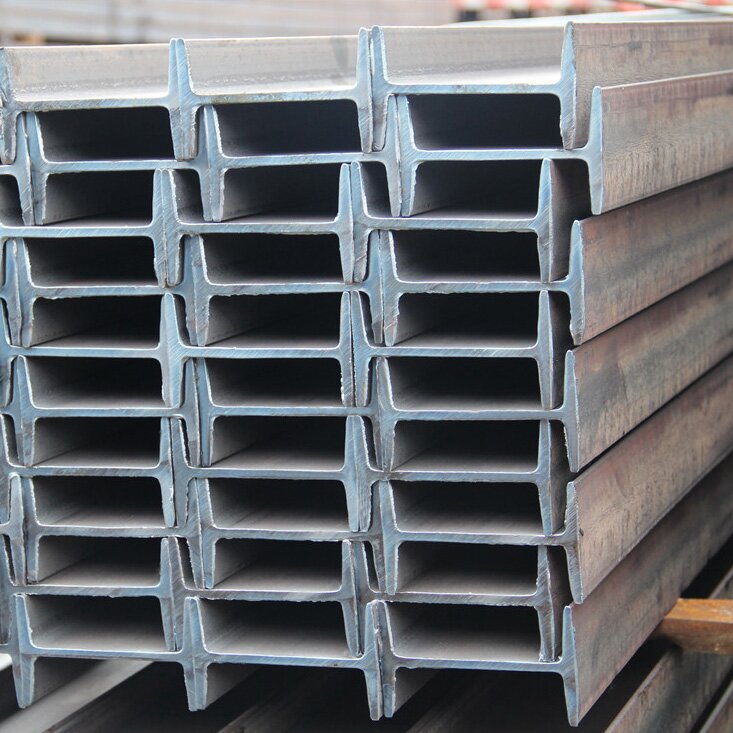

Product name |

I beam/Universal Beam |

Web height |

100-630mm or customize according to customer requirements |

Web Thickness |

4.5-17mm or customize according to customer requirements |

Flange width |

68-180mm or customize according to customer requirements |

Each weight |

5-50kgs or as customer requirements |

Grade |

S235JR,S275JR,S355JR,SS400,A36 |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Technique |

hot rolled |

MOQ |

5 tons |

The dimensions of I-beams are marked in accordance with the national standard (GB/T 706-2016) as "height (h) x leg width (b) x waist thickness (d)" (unit: mm), and are divided into ordinary I-beams (code "I", widely used) and lightweight I-beams (emphasizing lightweight). Ordinary I-beam waist height covers 100-630mm, commonly seen in I10 (100 × 68 × 4.5), I20a (200 × 100 × 7.0), I20b (200 × 102 × 9.0), I40A (400 × 142 × 10.5), etc. Some models come with "a/b/c" subtypes (slightly different waist thickness and leg width, with increased load-bearing capacity), suitable for heavy-duty scenarios such as building load-bearing and mechanical racks; The waist height of lightweight I-beams is mostly 50-200mm (such as Q10: 100 × 68 × 4.0), with narrow legs and thin waist, making them more lightweight and suitable for temporary construction, agricultural machinery, and other scenarios. The selection should be matched with the load, material (Q235/Q355, etc.), and installation requirements.

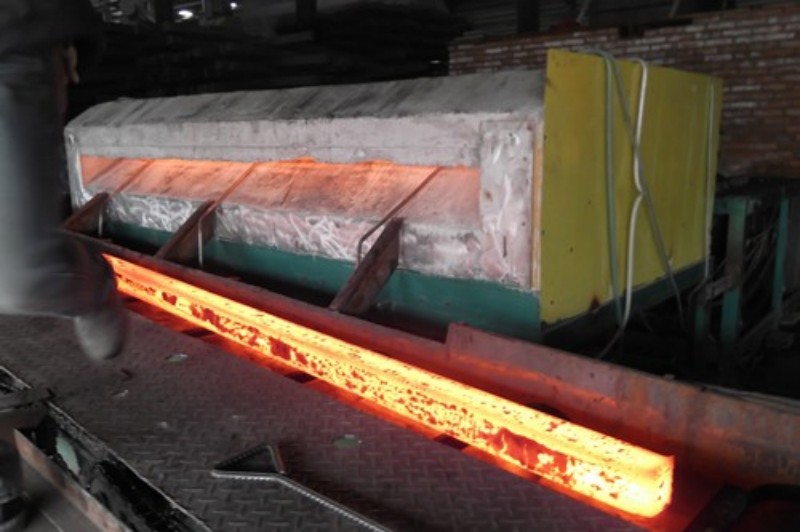

Production process

Raw Material Preparation

Select high-quality continuous casting billets or blooming billets, and control the composition, dimensions, shape, etc.

Production Process

Heating

Heat the billets in a heating furnace to a temperature range of 1100 - 1250°C.

Production Process

Rolling

Through rough rolling and finish rolling processes, shape the billets into the I-beam form.

Production Process

Cooling

After water cooling or air cooling, straighten the I-beams and grind away any defects.

Production Process

Straightening

After the performance inspection meets the standards, mark and package the I-beams for delivery.

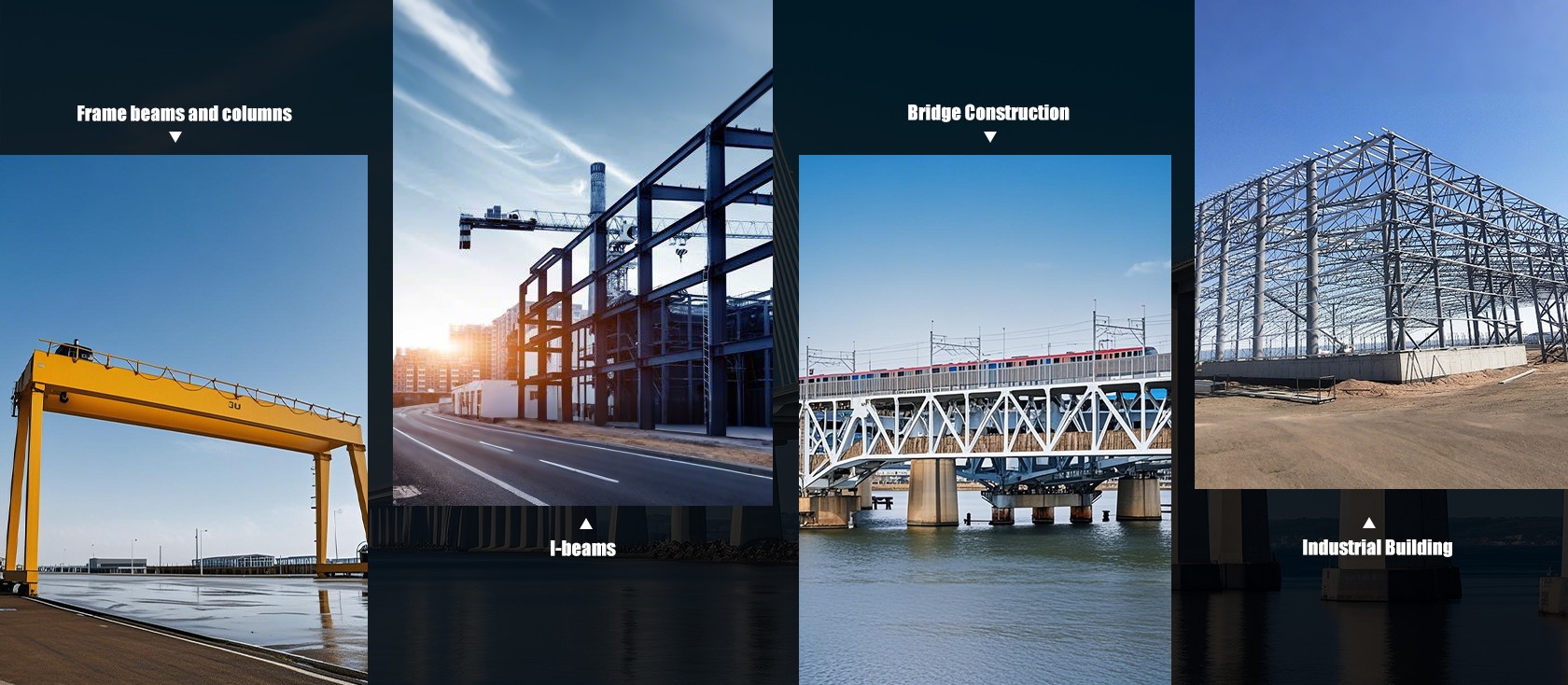

Production Application

Footwear abrasion solutions

I-beams are widely used:

This is a paragraph

Keywords: H-beam,I-section Beam,I Beam,Rolled Steel Joist,Wide Flange Beam,I-beam,Steel I-beam,hot rolled I-beam steel,Steel H-beam,Universal Beam (UB)