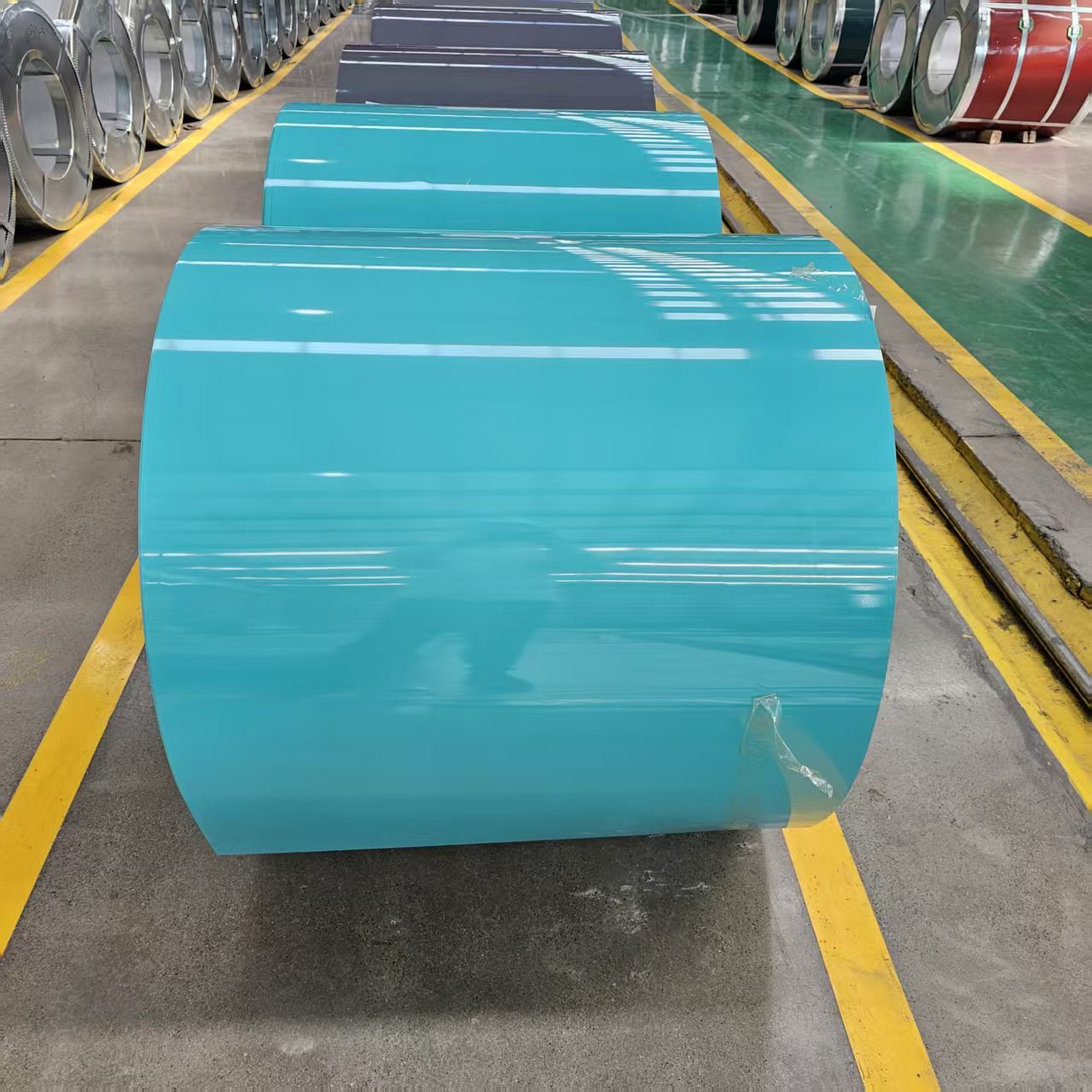

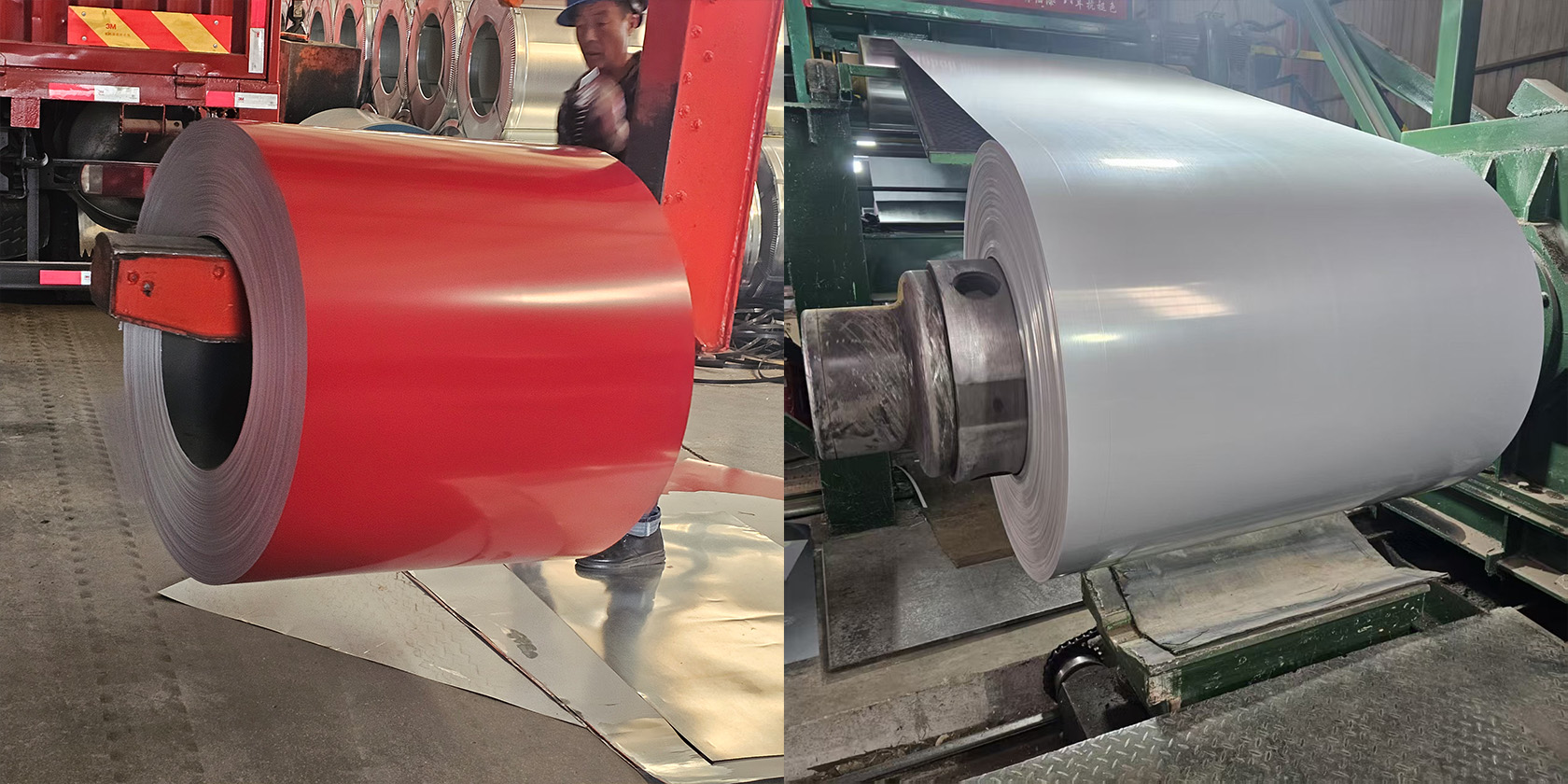

Low - Priced High Quality Hot - Dipped Colored Pre-painted Steel coils

description1

Production description

Product name |

Pre-painted Galvanized Steel Coil |

Thickness |

0.09-2.0mm, 0.326mm, 0.376mm, 0.426mm, 0.476mm, 0.5mm, 0.6mm or customer's requirement |

width |

800mm 900mm 914mm 1000mm 1100mm 1200mm 1250mm |

Roll weight |

3-10 tons or according To Customer's Demends |

Topcoat thickness |

10-40microns or customer's requirement |

Primer thickness |

5-20microns or customer's requirement |

Core Inner Diameter |

508/610mm |

Coating weight |

30-275g/m2 : 17g/m2 , 40g/m2 , 60g/m2 , 80g/m2 , 120g/m2 or customer's requirement |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN,ROCT |

Grade |

TDX51D+Z、TDX52D+Z、TDX53D+Z, TDC51D+Z, TDX51D+AZ, TDX51D+ZAM, TDC51D+AZ, TDC51D+ZAM, TSGCC, CCSB, CCSC |

Production process

Substrate Treatment

High-quality galvanized steel sheets are carefully selected and thoroughly cleaned of surface oil stains and rust through methods such as alkaline washing and acid washing, laying the foundation for the subsequent adhesion of the coating.

Production Process

Roll Coating of Primer

A high-precision roll coating device is used to evenly apply the primer, enhancing the bonding force between the substrate and the topcoat, and simultaneously improving the anti-corrosion performance.

Production Process

Color Coating of Topcoat

According to customers' requirements, the topcoat is applied using the roll coating or spraying process, endowing the prepainted galvanized steel coils with rich colors and an attractive appearance.

Production Process

Baking and Curing

The coated steel sheets are sent into a high-temperature baking furnace, enabling the coating to quickly solidify and take shape, and improving the hardness and wear resistance.

Production Process

Cooling and Quality Inspection

After the cooling treatment, the color, thickness, surface quality, etc. of the prepainted galvanized steel coils are strictly inspected to ensure that each coil meets the high-quality standards.

Production Application

Footwear abrasion solutions

1. Construction: Ideal for roofing, wall panels and architectural decoration, providing both protection and aesthetic appeal.

2. Home Appliances: Used in the production of refrigerator shells, washing machine exteriors, etc., ensuring durability and a stylish look.

3. Automotive: Applied to automotive parts like door panels, hood, trunk lid, dashboard and interior trims, combining strength with decorative features.

4. Furniture Manufacturing: Perfect for making cabinets, shelves, and other furniture, offering good corrosion resistance and attractive appearance.

5. Other fields: printer casings, computer cases, etc.