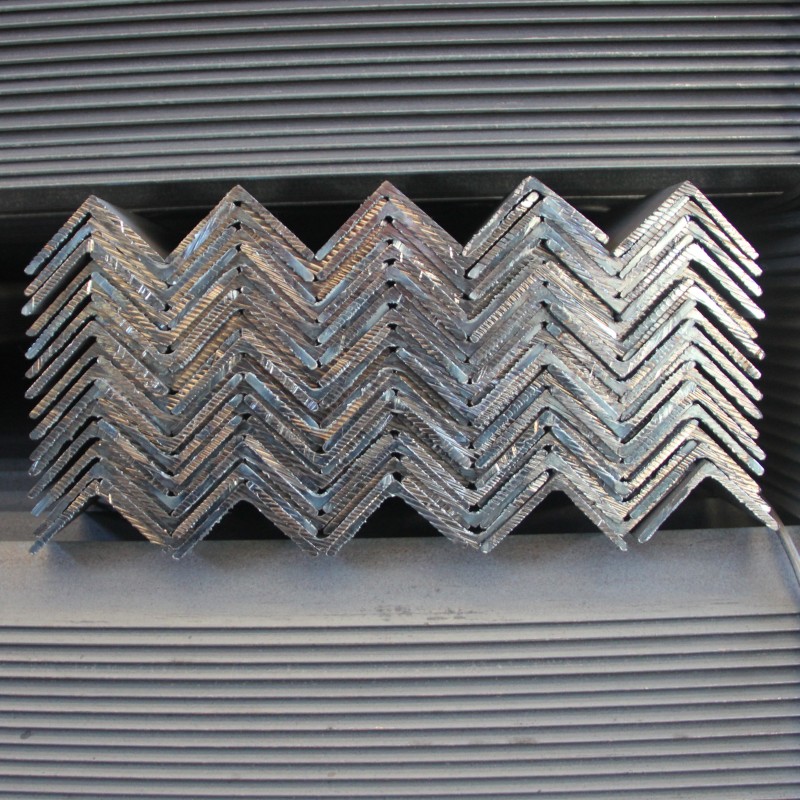

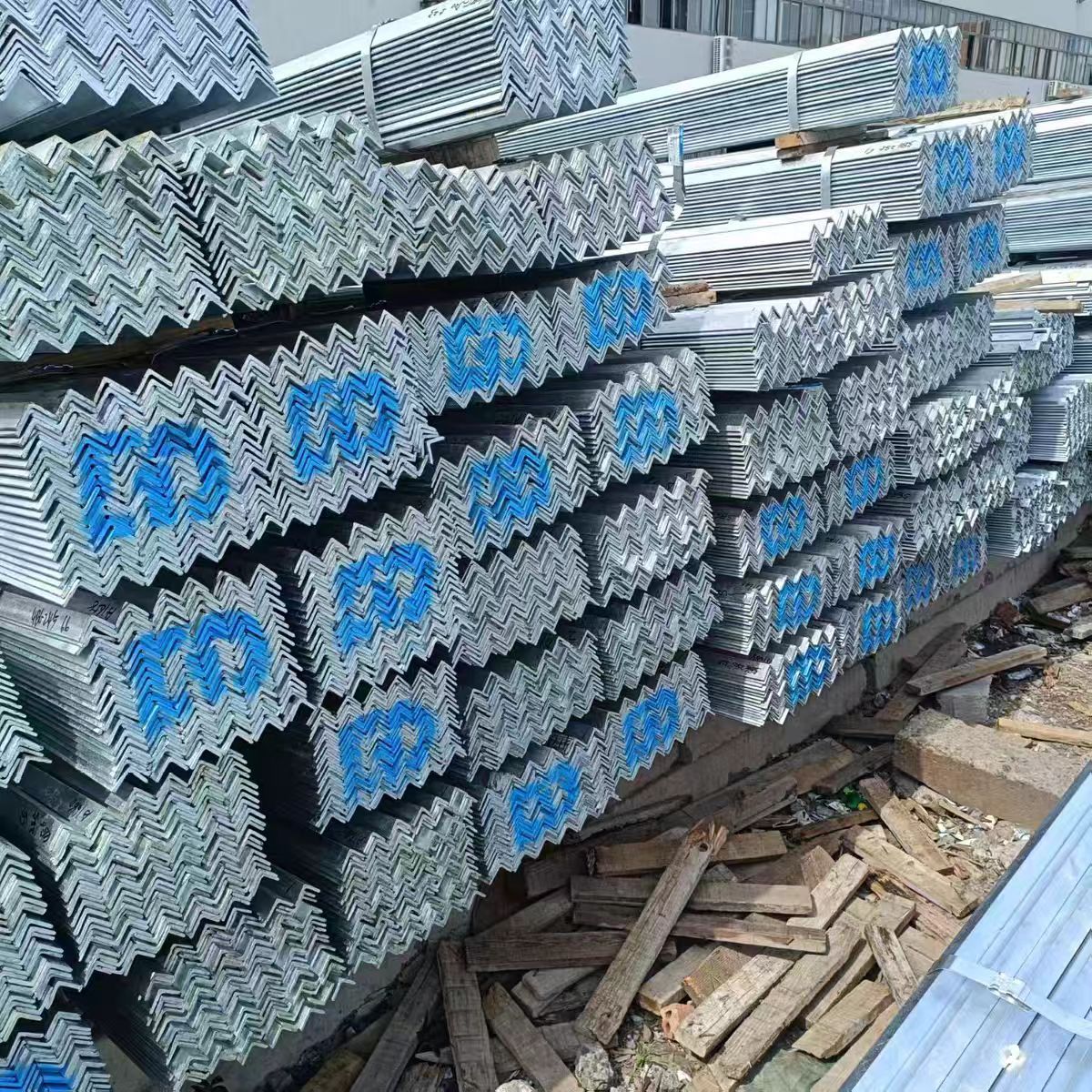

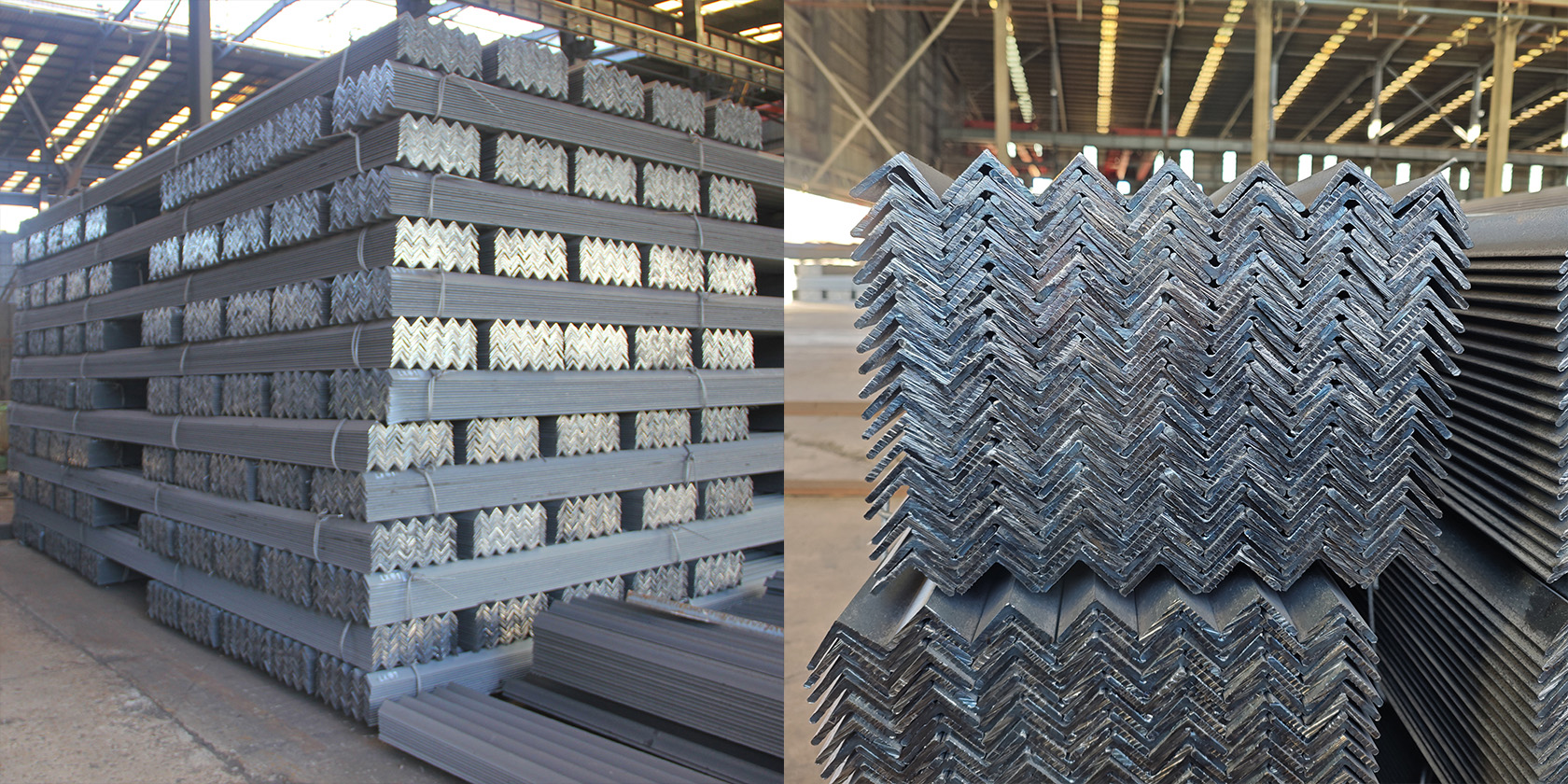

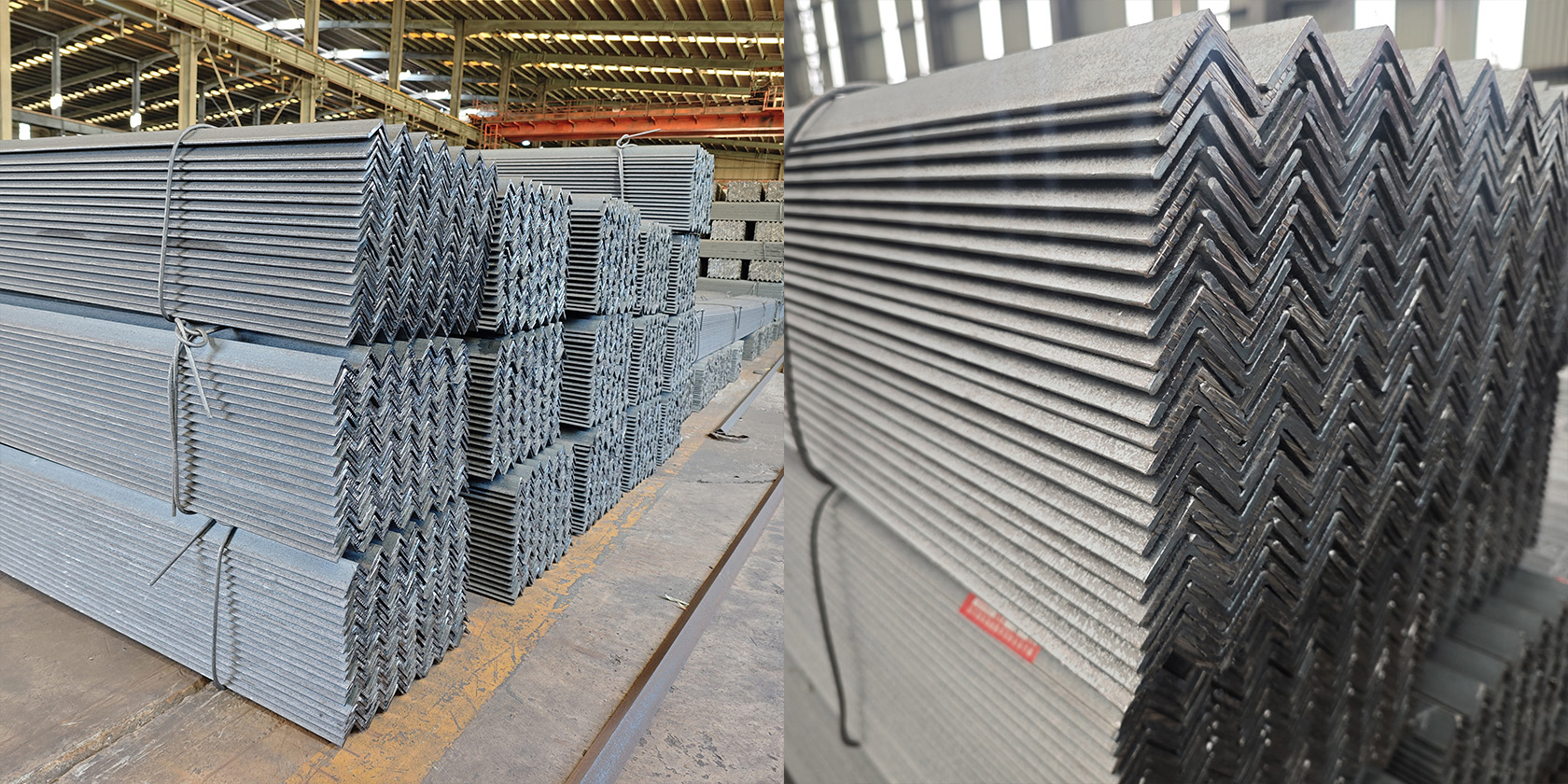

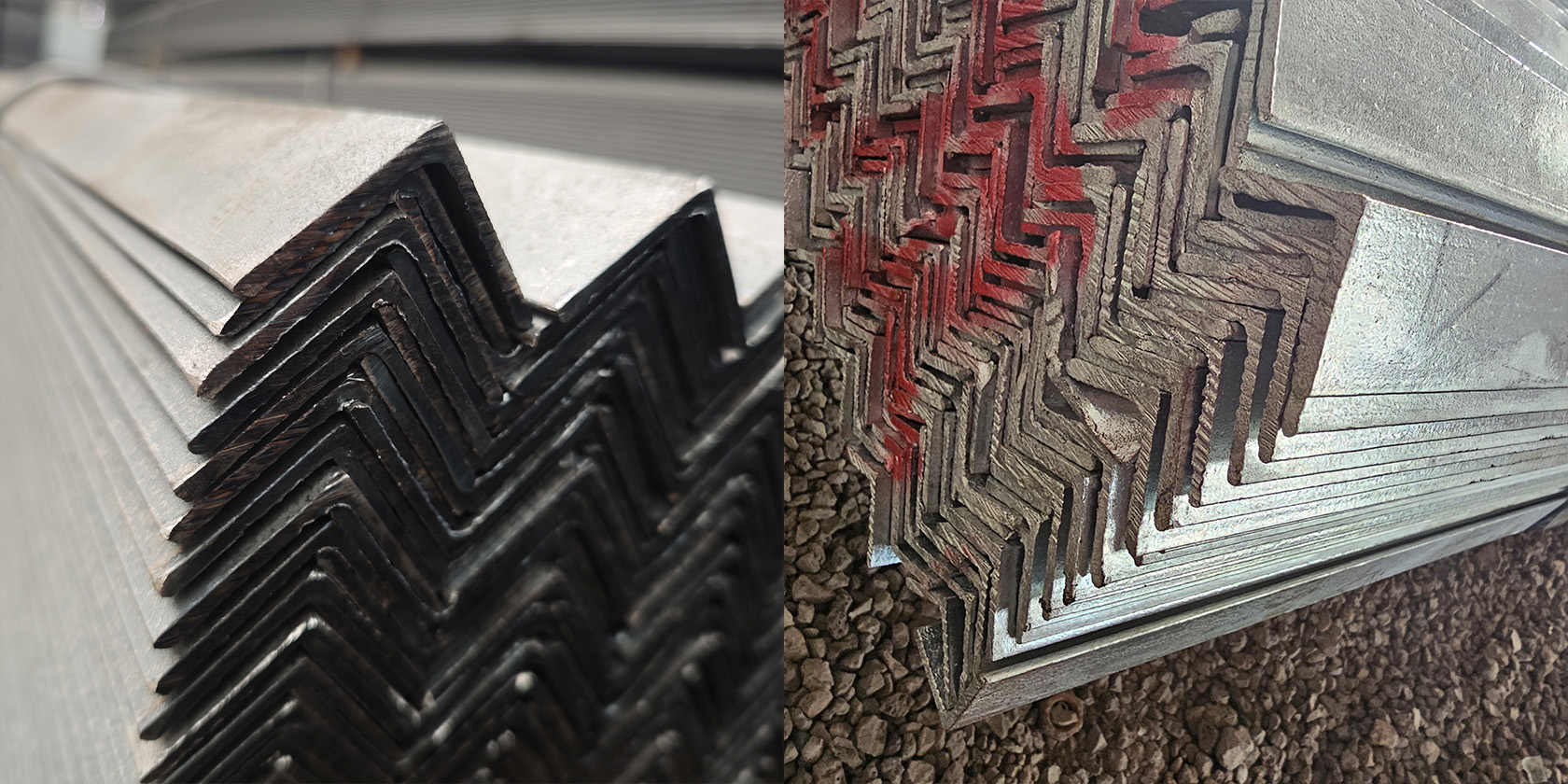

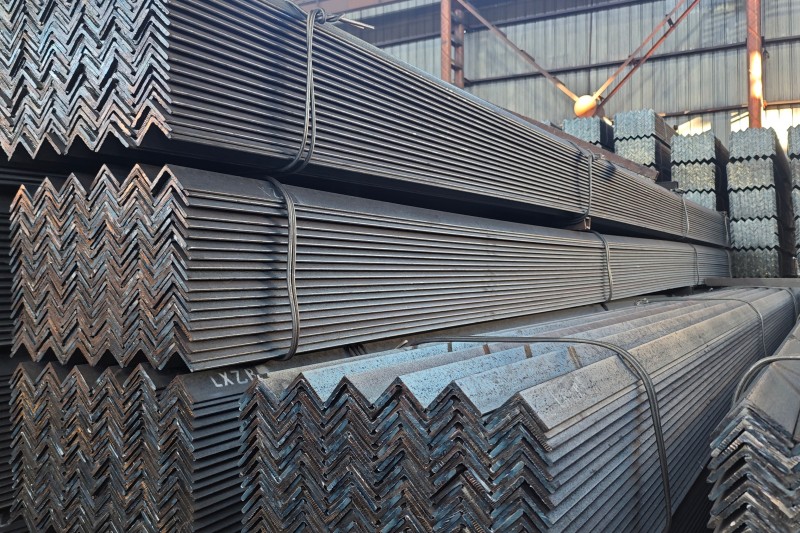

Manufacturer Stock Galvanized and Stainless Steel Triangle Iron Angle Steel

description1

Production description

Product name |

Angle bar |

Shape |

Equal; Unequilateral |

Width |

Equal:20-200mm;Unequilateral:25x16-200x125mm |

Thickness |

Equal:3-14mm;Unequilateral:3-16mm |

Length |

6m-12m or According To Customer's Demends |

Steel Grade |

Q235B,Q355B |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

MOQ |

5 tons |

The specifications and models of angle steel (triangle iron) are identified by "edge width x edge width x edge thickness" as the core (unit: mm), combined with parameters such as material, length, and surface treatment to form a complete model, such as "Q235B 50 × 50 × 56m". Among them, edge width is the core of specification division, commonly ranging from 25mm to 200mm, such as 25 × 25, 50 × 50, etc; The edge thickness determines the bearing capacity and is matched with the edge width, usually between 1.6mm and 20mm, such as 50 × 50 × 3 and 50 × 50 × 5. In terms of material, Q235 plain carbon steel has a tensile strength of 375-500MPa, which is cost-effective and suitable for room temperature, medium and low load scenarios; Q355 low-alloy steel has a tensile strength of 510-660MPa, suitable for low temperature, heavy load, and impact resistance scenarios. The standard length is 6m, 9m, 12m, and can also be customized to any length of 1-12m as needed. In terms of surface treatment, black skin does not have rust prevention treatment and is only used for indoor dry and non exposed scenes; Hot dip galvanized zinc layer with a thickness of 85 μ m or more, resistant to salt spray and moisture, suitable for outdoor, outdoor, and coastal scenes; Spray painted/passivated paint film thickness of 30-50 μ m, suitable for indoor mild corrosive environments.

Production Application

Footwear abrasion solutions

1. Construction: Used for building frames, like beams and columns in plants, bridges, and high - rises; also for scaffolding.

2. Shipbuilding: Forms part of hull skeleton, strengthens structure; used for cabin supports and frames.

3. Machinery: Makes equipment supports and frames, stabilizes machinery operation; for mechanical transmission fixing.

4. Daily Life: For shelves, storage racks; also in door/window frames, furniture, and fences.

Production process

Billet Preparation

Select qualified steel billets and strictly control the quality.

Production Process

Heating

Heat up to 1100 - 1250℃ to improve plasticity.

Production Process

Rolling

Through multiple passes of rolling, form an L-shaped cross-section.

Production Process

Cooling

Cool naturally on the cooling bed to stabilize the structure.

Production Process

Straightening

Correct the deformation to ensure dimensional accuracy.

Production Process

Inspection

Check the appearance, dimensions, and mechanical properties.

Production Process

Packaging and Delivery

Package the qualified products according to requirements and deliver them.