The global steel products market is witnessing steady growth in 2025, with steel galvanized wire, black annealed iron wire, and metal mesh leading demand across construction, agriculture, infrastructure, and daily manufacturing sectors. Driven by urbanization, green manufacturing policies, and rising demand for durable materials, these products are continuously evolving to meet higher performance and sustainability standards.

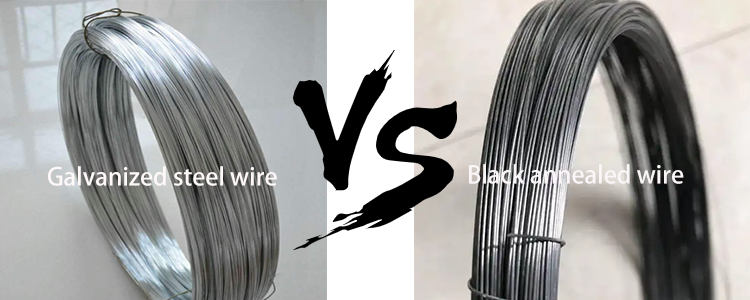

Galvanized Steel Wire remains a staple for outdoor applications, thanks to its

Zinc Coating that delivers superior corrosion resistance—even in humid, coastal, or industrial environments. The global market for this product is projected to reach $3.987 billion in 2025, with the Asia Pacific region accounting for 36.8% of the total share. Innovations like Tata Steel’s Magizinc® coating reduce zinc usage by 50% while boosting durability by 30%, making it ideal for power grid construction, marine cable protection, and outdoor fencing.

Meanwhile, annealed wire stands out in indoor and low-corrosion scenarios where flexibility is key. Through controlled heat treatment, it gains exceptional ductility—allowing easy bending without cracking—making it indispensable for packaging, handicrafts, and wire mesh production. Its natural black oxide finish also keeps costs lower, suiting applications where long-term outdoor corrosion resistance isn't a priority.

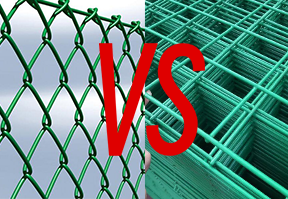

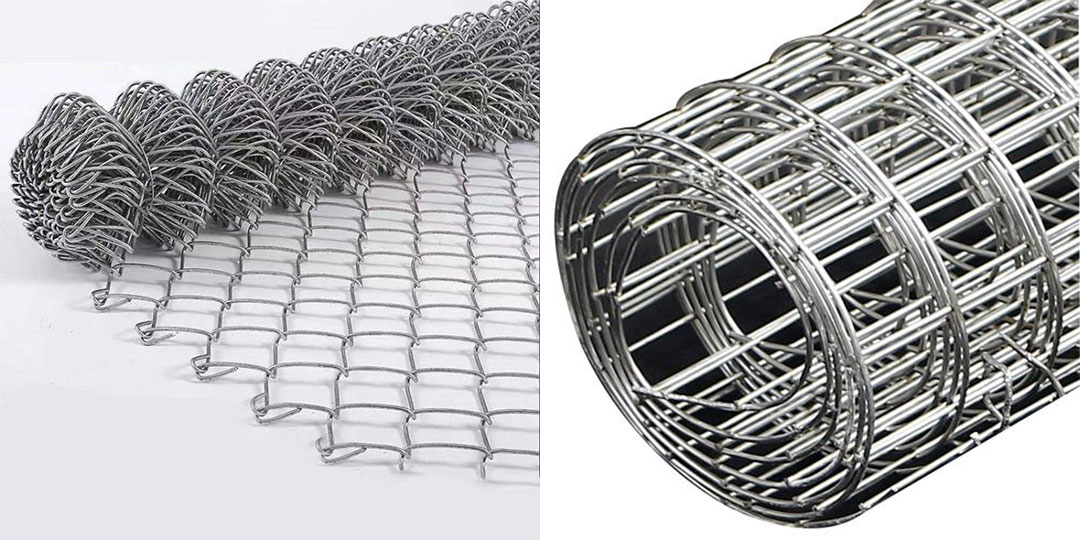

For metal mesh, 2025 growth is fueled by two core technologies: woven and welded, each serving distinct needs.

Woven metal mesh is made by interlacing warp (vertical) and weft (horizontal) wires via industrial looms. Its unfixed intersections give it flexibility, letting it bend to irregular shapes—perfect for livestock fencing, construction safety nets, and insect screens. It excels at fine filtration (apertures below 1/4 inch) for chemical purification, food grading, and water treatment, with 2025 bringing more customizable wire diameters and patterns.

Welded metal mesh uses spot-welding at wire intersections to create a rigid grid, offering strong load-bearing and shape stability. It dominates large-aperture (above 1/4 inch) uses like concrete reinforcement, highway guardrails, and storage rack flooring. The global welded mesh market will hit $352 billion in 2025 (with $71.2 billion from galvanized variants), supported by advancements like Voestalpine’s aerospace-grade mesh and ArcelorMittal’s low-carbon options. Automated lines also cut energy use by 15%.

Across both types, AI quality control slashes waste by 18%, while ISO 14001-certified recyclable stainless steel mesh is preferred by 42% of European firms for sustainability.

Regional demand trends highlight opportunities: RCEP boosted galvanized wire exports to Southeast Asia by 23%, and the U.S. Infrastructure Act earmarks $50 billion for projects needing metal mesh.

To choose the right product: galvanized steel wire for outdoor durability, annealed wire for flexibility, steel woven mesh for adaptability/filtration, and steel welded mesh for strength. As the industry shifts to low-carbon production, these products remain key for sustainable infrastructure.