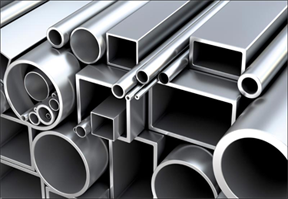

Galvanized round pipe and galvanized square pipe: difference analysis and application scenario comparison

1、 Shape: The Key to Determining Core Performance

The shape is the most intuitive difference between the two, which directly affects their performance characteristics.

(1) Galvanized round pipe: streamlined, evenly stressed

Galvanized round pipes have a circular cross-section and belong to streamlined pipes. It is made by heating round Steel Billets, punching and rolling them, and then galvanizing them. This shape has two obvious advantages:

Uniform force distribution: Whether subjected to internal pressure (such as water or gas transmission) or external pressure (such as buried underground), the pressure can be evenly distributed along the circumference, making it less likely for local excessive force to cause rupture;

Low fluid resistance: The inner wall is smooth without edges and corners, used for transporting water, oil, gas, etc., which can reduce friction and improve transportation efficiency.

From the appearance, the circular pipe has smooth lines, uniform wall thickness, and is easy to cut, weld, and bend. It is particularly suitable for scenarios that require bending into an arc shape, such as pipe bends or curved parts of greenhouse supports.

(2) Galvanized square tube: with sharp edges and stronger riGIdity

Galvanized square tube has a square or rectangular cross-section (known as "square rectangular tube" in the industry), mostly made by cutting hot-Rolled Steel strips into suitable widths, rolling them into squares or rectangles with a cold bending machine, and then welding and galvanizing them.

Its core advantage is strong rigidity. Due to the presence of right angled edges, when subjected to vertical or horizontal pressure and tension, the "support" formed by the edges can disperse external forces and prevent bending and deformation. For example, using circular and square tubes of the same specifications to make shelf columns, square tubes can withstand heavier goods without tilting. In addition, the outer wall of the square tube is flat, and when connected to plates, brackets, etc., Bolt fixing and welding are more convenient, suitable for scenarios that require splicing and assembly.

2、 Size specifications: Different standards and representation methods

The dimensions of the two follow different standards, and there are significant differences in parameter definitions and writing methods, which also affect the selection of applicable scenarios.

(1) Galvanized round pipe: look at "diameter+wall thickness"

The size of circular pipes is mainly determined by three parameters: nominal diameter (DN), outer diameter (De), and wall thickness (S). The commonly used standard in China is GB/T 3091-2015 "Welded Steel Pipes for Low Pressure Fluid Transport".

Nominal diameter (DN): It is not the actual pipe diameter, but a "nominal size" determined for the convenience of design and construction, such as DN15 (4 pipes), DN20 (6 pipes), DN50 (2-inch pipe);

Outer diameter (De): The actual diameter of the outer wall of the pipeline, which is crucial for processing and installation. For example, DN15 corresponds to an outer diameter of approximately 21.3mm, and DN50 corresponds to approximately 63.5mm

Wall thickness (S): determines the pressure bearing capacity and weight of the pipeline, commonly ranging from 1.0mm to 12mm. For example, DN50 round pipes have different wall thicknesses such as 2.75mm (ordinary) and 3.5mm (thickened).

The outer diameter range of circular pipes is very wide, ranging from DN10 (outer diameter 17.2mm, used for precision instrument oil transportation) to DN800 (outer diameter 820mm, used for municipal drainage). The same outer diameter can be matched with multiple wall thicknesses to meet different pressure requirements.

(2) Galvanized square tube: look at "side length/length width+wall thickness"

The core dimensions of square tubes are "side length (or length x width)" and "wall thickness". The commonly used domestic standard GB/T 6728-2017 "Cold formed Hollow Steel for Structural Use" is written as "side length x side length x wall thickness" (square) or "length x width x wall thickness" (rectangle). For example:

Square tube: 50 × 50 × 3 (side length 50mm, wall thickness 3mm), 100 × 100 × 5 (side length 100mm, wall thickness 5mm);

Rectangular tube: 60 × 40 × 2.5 (length 60mm, width 40mm, wall thickness 2.5mm), 150 × 80 × 4 (length 150mm, width 80mm, wall thickness 4mm).

The side length of the square tube is generally 20mm-600mm (larger sizes need to be customized), with a wall thickness of 1.0mm-16mm. Different wall thicknesses can be matched for the same side length, balancing "rigidity" and "lightness". For example, 30 × 30 × 1.5 thin-walled square tubes are used to build temporary activity rooms, and 100 × 100 × 8 thick walled square tubes are used for heavy machinery load-bearing brackets.

It is worth mentioning that under the same material and weight, the "bending resistance" (measured by the moment of inertia of the cross-section) of square tubes is stronger than that of circular tubes. For example, a 50 × 50 × 3 square tube has a cross-sectional moment of inertia of about 102cm ⁴, while a circular tube with an outer diameter of 57mm and a wall thickness of 3mm has only about 68cm ⁴, which is why square tubes are more suitable for load-bearing.

3、 Main purpose: Each has its own focus and clear division of labor

Based on the differences in shape and size, the division of labor between the two is very clear in practical applications. Circular pipes focus on "conveying", while square pipes focus on "supporting", although there are also a few intersecting scenarios.

(1) Galvanized round pipe: focusing on "conveying" and "simple support"

Fluid transportation: This is the main purpose of circular pipes,especially seamless steel pipes. Due to its smooth inner wall and uniform force distribution, it is widely used for water transportation, natural gas, oil, heating and hot water supply. For example, DN20-DN50 round pipes are used for residential building tap water, DN100-DN300 thick walled round pipes are used for municipal natural gas main pipelines, and DN50-DN150 thin-walled round pipes are used for agricultural irrigation.

Simple support and framework: For scenarios with low rigidity requirements, circular pipes are very practical due to their ease of processing. For example, vegetable greenhouse brackets (curved with DN20-DN32 circular pipes), temporary fence posts (DN40-DN50 circular pipes), and simple frames for small billboards. In addition, circular pipes are commonly used in mechanical transmission shafts and hydraulic oil pipes to achieve rotation or sealing through circular structures.

Other scenarios: For places that value "beauty", a streamlined appearance with a round tube is more suitable, such as park corridor columns and community fitness equipment brackets; Moreover, it has no sharp edges and is suitable for use as a children's playground equipment, reducing the risk of collisions.

(2) Galvanized square tube: focusing on "structural support" and "frame construction"

Building and municipal support: This is the core use of square tubes. Due to its strong rigidity and ease of splicing, it is commonly used as a load-bearing component in buildings, such as steel structure factory purlins (using 100 × 50 × 3 rectangular tubes), office building glass curtain wall brackets (using 80 × 80 × 4 square tubes), and balcony guardrail columns (using 50 × 50 × 2.5 square tubes). In municipal engineering, square tubes are also commonly used for streetlight poles (rectangular tubes, convenient for installing lamp arms) and traffic sign brackets (using thick walled rectangular tubes of 120 × 60 × 5).

Mechanical and equipment frame: The outer wall of the square tube is flat, which facilitates the fixation of components and is the preferred choice for mechanical equipment frames. For example, the base of a CNC machine tool (using thick walled square tubes of 200 × 100 × 8), the conveyor frame of an assembly line (using rectangular tubes of 60 × 40 × 3), and the columns and beams of shelves (using square tubes of 50 × 50 × 3 or 80 × 40 × 3). Electric vehicles and tricycles also commonly use square tube frames to ensure stable driving through rigidity.

Decoration and Furniture: Square tubes have sharp edges and are suitable for modern minimalist styles, such as mall display cabinet frames (using 40 × 40 × 2 thin-walled square tubes), home wrought iron sofa frames (using 30 × 30 × 1.5 square tubes), and restaurant partition screens (using 20 × 20 × 1 square tubes welded into a grid). It can support and create various shapes through splicing.

4、 Summary: Select according to needs and leverage advantages

Although galvanized round pipes and galvanized square pipes are both galvanized pipes, their performance and applications vary greatly due to their different shapes

Galvanized round pipe: achieves "uniform force distribution" and "low fluid resistance" through a circular cross-section, with the core advantage of "transportation", suitable for fluids such as water, gas, oil, and simple support scenarios with low rigidity requirements;

Galvanized square tube: achieves "strong rigidity" and "easy splicing" through square cross-section, with the core advantage of "support", suitable for scenarios with high stability and strength requirements such as building structures, mechanical equipment frames, and load-bearing brackets.

When selecting materials, focus on the requirements: to transport fluids, prioritize circular pipes and choose wall thickness based on pressure; To provide structural support, square pipes are preferred, and the side length and wall thickness are selected based on the load-bearing capacity. In addition, it is also possible to consider whether the construction is convenient (such as easier welding of square pipes) and the cost (thick walled square pipes of the same specification are slightly more expensive than round pipes), so that the selected materials are both practical and cost-effective.