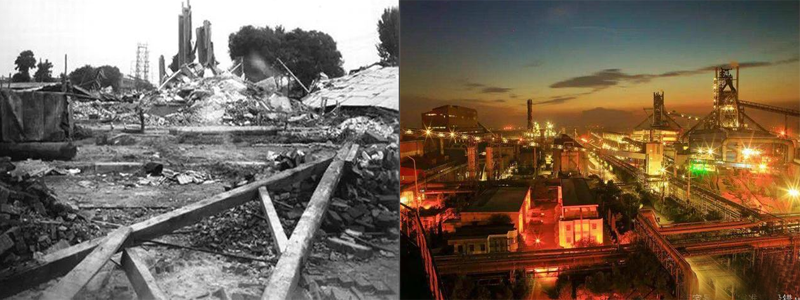

The 49-year rebirth history of Tangshan Iron and Steel after the earthquake!

Post-Quake Rebirth: The Will of Steel Shapes the City's Backbone

Tangshan, a city deeply etched with the mark of steel, saw the seeds of its Steel Industry sown as early as the early 20th century. In 1925, Tangshan Qixin Cement Company successfully smelted the first batch of steel in North China, a pioneering feat that illuminated the path for Tangshan's steel industry. Over the next half-century, leveraging its abundant coal and iron resources and advantageous geographical location, Tangshan's steel sector thrived. In 1949, Tangshan's total industrial output value was a mere 112 million yuan; by 1975, this figure had surged to 2.941 billion yuan, 26.26 times that of 1949.

The 1976 earthquake dealt a devastating blow: numerous Tangshan Iron And Steel (Tanggang) employees and their families perished, equipment was severely damaged, and fixed-asset losses reached roughly one-third. Yet Tanggang workers refused to be defeated. After burying their loved ones and drying their tears, they rushed to resume production—many working with bandages still wrapped around their wounds. On August 25, 1976, the first batch of "earthquake-resistant aspirational steel" poured forth. The fiery red molten steel, glistening with the tears of steelworkers, symbolized unyielding hope. This batch was immediately used to build quake shelters and temporary hospitals, a beacon of revival for the steel industry and a declaration of Tangshan's defiance against fate.

Within four days of the quake, 100,000 PLA soldiers, 20,000 medical personnel, and 30,000 technical workers raced to assist. Kailuan Coal Mine worker Li Yulin's daring drive to Zhongnanhai to report the disaster became a call to national action. Coal production resumed on the 10th day; power grids were reconnected on the 14th; the first steel was smelted on the 28th. Reconstruction planning began within half a month, industrial production fully recovered in a year, and output surpassed pre-quake levels by the second year. By the end of June 1986, Tangshan's reconstruction was complete, with 98.5% of residents in new homes by year's end. Through trials, resolve only grew: in a decade, a more prosperous Tangshan rose from the ruins. The Tangshan earthquake resilience spirit, inspiring miracles,became "an integral part of the Chinese national spirit."

Steel Industry Growth After Reform and Opening-Up

China's reform and opening-up brought new opportunities to Tangshan's steel sector. Post-quake, Tanggang expanded production: in 1979, it became a pilot for expanded enterprise autonomy in Hebei Province. It formulated a master plan for expansion and renovation, launching large-scale technological upgrades in 1986. During the Seventh and Eighth Five-Year Plans, targeting shortages of iron, ore, and coke, Tanggang prioritized ironmaking expansions, building 2 iron mines, 7 collective mines, 2 36-coke ovens, 2 1,260m³ blast furnaces, and 6 continuous casters. It imported a high-speed Wire Rod mill and a continuous bar mill, forming an integrated production capacity of 2 million tons of iron, steel, and rolled products. This eliminated gaps in pre-steelmaking processes, elevating Tanggang from a provincial leader to a national advanced enterprise.

Private capital injected vitality into the industry. Tangshan's unparalleled resource endowment and location made it fertile ground for private steel firms: rich coal reserves (e.g., Kailuan Mine) ensured energy; abundant surrounding iron ore secured raw materials; and ports like Jingtang and Tangshan Port facilitated low-cost transport, expanding market reach. By the 12th Five-Year Plan, Tangshan's steel output accounted for ~50% of Hebei's and over 1/7 of China's total. In 2005, it contributed half of Hebei's steel production, with GDP exceeding 200 billion yuan to top Hebei. Steel-centric industrial chains became the "backbone" of the city's economy, driving growth. Behind this boom was the fusion of earthquake resilience and market dynamism—Tangshan people, as in reconstruction, turned policy opportunities into growth momentum.

Transformation Pressures and Capacity Cuts Amid Rapid Growth

As times changed, flaws in Tangshan's traditional steel model emerged: overcapacity led to stockpiles, hindering upgrading; high energy consumption and pollution (smog-choked skies, polluted rivers) made resource-driven growth unsustainable. 2013 marked a turning point: nationwide anti-pollution efforts began, with Tangshan labeled a "smog hotspot." It recognized the need to shift to sustainable industries, upgrading traditional sectors to high-end, precision, and sophisticated products via green transformation.

By 2016, Tangshan's steel sector crossed a critical threshold: new growth drivers emerged, a new development pattern took shape, and GDP reached 630.62 billion yuan. In 2017, GDP exceeded 700 billion yuan, with tertiary industry growing 10.9%—outpacing primary and secondary sectors—showcasing effective structural adjustment. On August 13, 2018, Guofeng Iron and Steel dismantled equipment, cutting massive capacity. Since 2013, Tangshan has reduced steelmaking capacity by 49.69 million tons—50% of China's total.

Green Transformation: From "Black Chimneys" to Eco-Friendly Mills

Recent years have seen remarkable progress in green development. HBIS Tangsteel led the way: demolishing 3 450m³ blast furnaces, it converted 1/5 of the freed land to green space. Investing 3.18 billion yuan in 32 energy-saving and emission-reduction projects, it generates over 75% of electricity from secondary energy, boosting annual efficiency by 300 million yuan. Industrial wastewater recycling saves enough water yearly to fill Hangzhou's West Lake. Tangsteel's success boosted confidence in traditional industries' transformation.

After relocating to Leting Economic Development Zone in 2020, Tangsteel upgraded equipment and technology, significantly improving smelting precision, efficiency, and product quality. Its products—used in automotive manufacturing, machinery, infrastructure, and bridges—serve domestic and over 100 global markets. It holds national A-level environmental performance status and is among China's first batch of green factories.

Other steel firms increased environmental investment, adopting advanced technologies: efficient desulfurization, denitrification, and dust removal for waste gas; comprehensive recycling systems for industrial wastewater. Factories transformed into tree-lined spaces. Tangshan now hosts 19 national and 26 provincial green factories, achieving full coverage. In 2024, 26 operational steel enterprises attained national A-level status—more than any other city in China.

Intelligentization and Upgrading: Old Wisdom Meets New Tech

Amid the intelligentization wave, Tangshan's steel industry embraces new technologies. In 2024, the municipal government partnered with Baidu Intelligent Cloud to develop a steel industry large model. Baidu's team digitized veteran steelworkers' "fire-watching" expertise to train the model, integrating deep learning algorithms with industrial software to transition from "experience-based steelmaking" to "AI-driven steelmaking," translating "heat control" into digital commands. This reduces costs by ~30 yuan/ton, with plans to scale. Tangshan will deepen cooperation with Baidu to integrate the real economy and digital economy.

The Trillion-Yuan Formula: Synergistic Growth of Steel and Ports

In 2024, Tangshan became Hebei's first city with GDP exceeding one trillion yuan (1.00039 trillion yuan), driven by the "dual engines" of steel and ports. On the Bohai Bay, Tangshan Port—home to 400,000-ton berths—handled 842 million tons in 2023 (ranking 2nd globally), with steel product exports accounting for 15% of China's total. The "steel + port" synergy lowers logistics costs by 12-15% compared to inland firms.

Shougang Jingtang—key to Shougang's relocation—thrives in Tangshan, with leading market shares in automotive sheet, electrical steel, and tinplate. It has attracted supporting enterprises to Caofeidian, forming a complete industrial chain. From 2014 to December 2024, Tangshan implemented 948 Beijing-Tianjin cooperation projects worth over 100 million yuan each, totaling 606.592 billion yuan in investment (491.775 billion yuan completed). Leading Hebei in relocated projects and investment, these initiatives brought advanced technologies, management expertise, and market resources, driving steel industry upgrading.