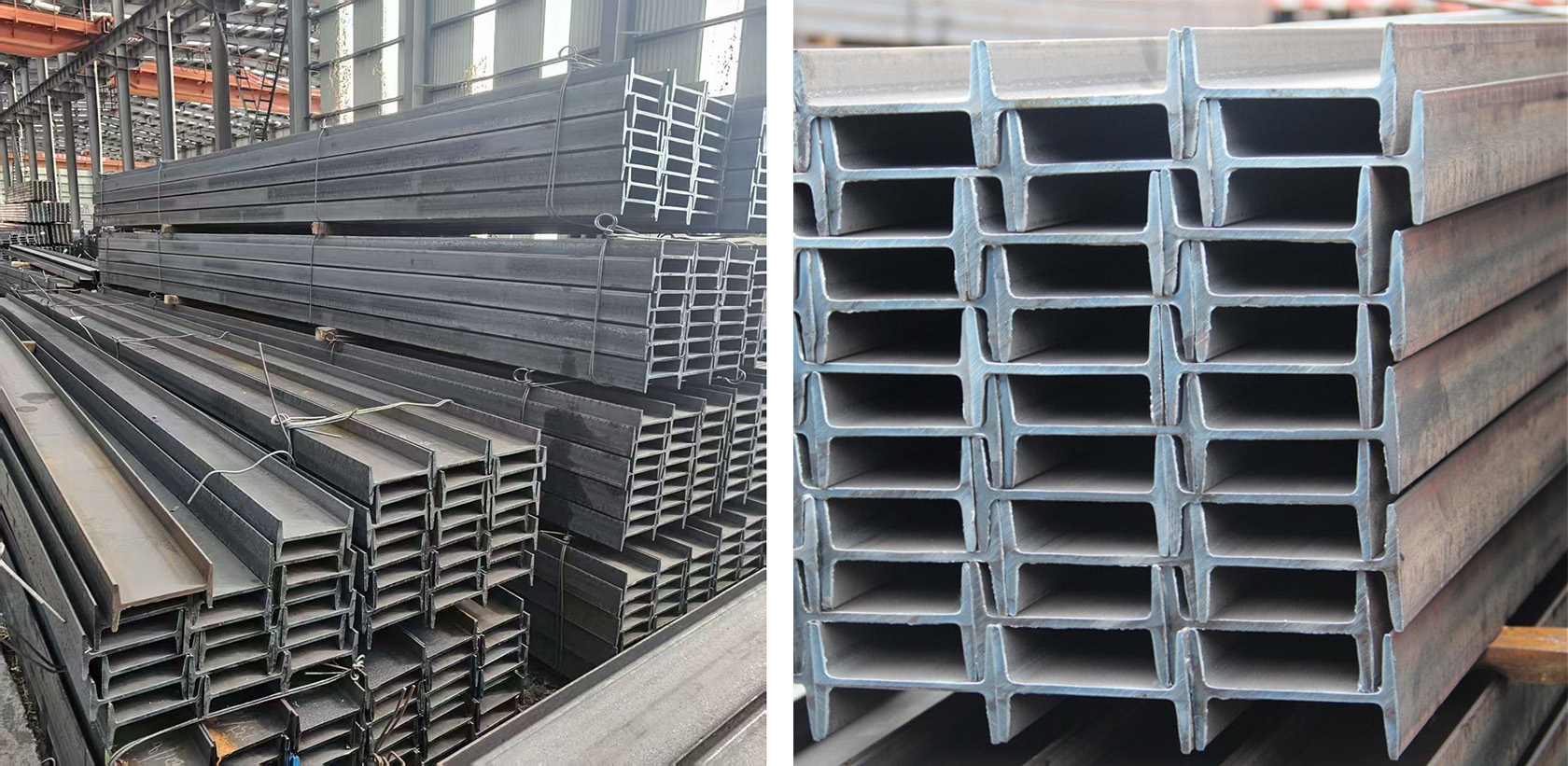

Understanding H-Beams vs. I-Beams: A Guide to Structural Steel Profiles

In the world of Structural Steel, H-beams and I-beams are two of the most widely used profiles, offering unique advantages for construction, infrastructure, and industrial applications. While they may appear similar at first glance, their design differences significantly impact performance and suitability for specific projects. Here’s a breakdown of their characteristics and key distinctions:

What Are H-Beams and I-Beams?

H-Beam (H-Shaped Steel)

● Design: Features a symmetrical "H" shape with equal-width flanges (top and bottom) connected by a vertical web. The flanges and web are typically of uniform thickness.

● Strength: Optimized for load-bearing efficiency, H-beams distribute weight evenly across both flanges and the web, making them ideal for vertical and horizontal support in heavy-duty structures.

● Applications: Commonly used in high-rise buildings, bridges, industrial platforms, and large-span structures where high strength-to-weight ratios are critical.

I-Beam (I-Shaped Steel)

● Design: Resembles the letter "I," with tapered flanges that narrow toward the edges and a thinner web compared to H-beams. The inner flange surfaces slope slightly (typically 6–12%).

● Strength: Excels in handling bending stress due to its tapered flanges, which concentrate material where stress is highest.

● Applications: Frequently used in residential construction, small-to-medium bridges, and machinery frames where moderate loads and cost efficiency are priorities.

Key Differences Between H-Beams and I-Beams

| Feature | H-Beam | I-Beam |

| Flange Design | Wide, parallel flanges | Narrow, tapered flanges |

| Web Thickness | Thicker web for enhanced stability | Thinner web, optimized for flexibility |

| Weight Distribution | Evenly distributes axial loads | Focuses strength along the neutral axis |

| Material Efficiency | Higher strength-to-weight ratio | Lower material usage for lighter loads |

| Production Complexity | Requires precision rolling techniques | Simpler manufacturing process |

Why Choose H-Beam?

● Heavy Load Capacity: Ideal for columns, trusses, and foundations in skyscrapers, warehouses, and industrial plants.

● Stability: Uniform thickness reduces buckling risk under compression.

● Sustainability: Reduced material waste due to optimized cross-sectional design.

Why Choose I-Beam?

● Cost-Effectiveness: Lower production costs make it economical for smaller projects.

● Bending Resistance: Tapered flanges excel in horizontal applications like floor joists and crane rails.

● Ease of Installation: Lighter weight simplifies handling and assembly.

Industry Trends

With the rise of green building practices, H-beams are increasingly favored for their efficiency in modular construction and renewable energy projects (e.g., wind turbine towers). Meanwhile, I-beams remain a staple in retrofitting older structures and reGIons with cost-sensitive infrastructure needs.

Trust Tangshan Jinxuan for Premium Solutions

We supply a full range of H-beams and I-beams tailored to global standards (ASTM, EN, JIS), available in customized sizes and grades (e.g., S355JR, Q235). Our technical team ensures optimal profile selection for your project’s safety, durability, and budget.

Contact us today to discuss your structural steel requirements!