Top Exporters & Suppliers of Quality Coatings for Painting Galvanized Steel

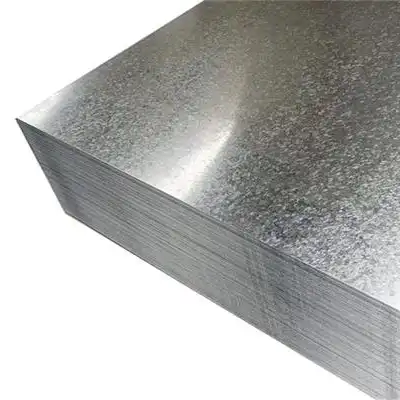

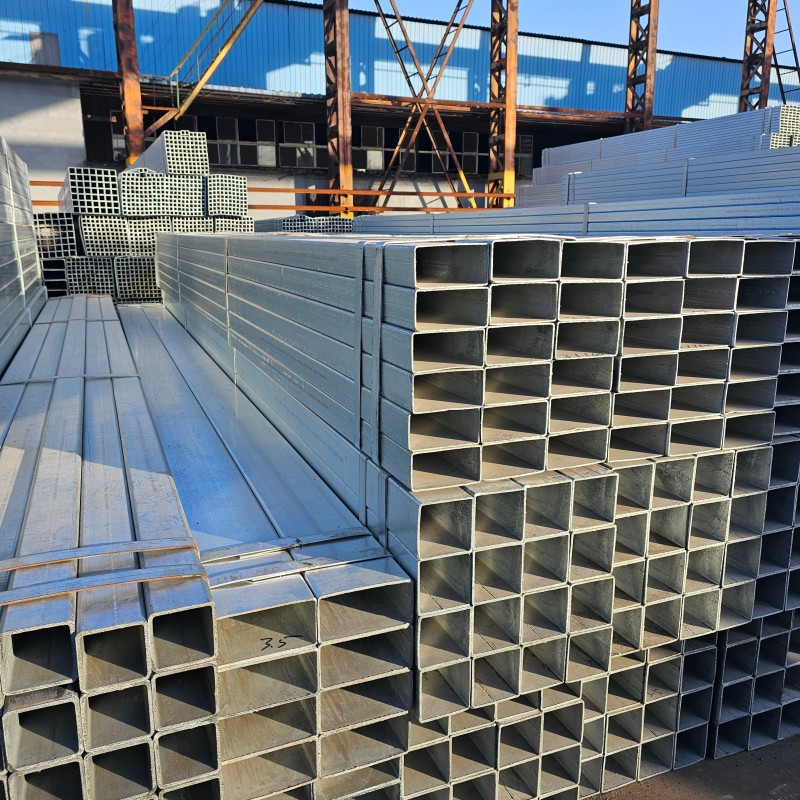

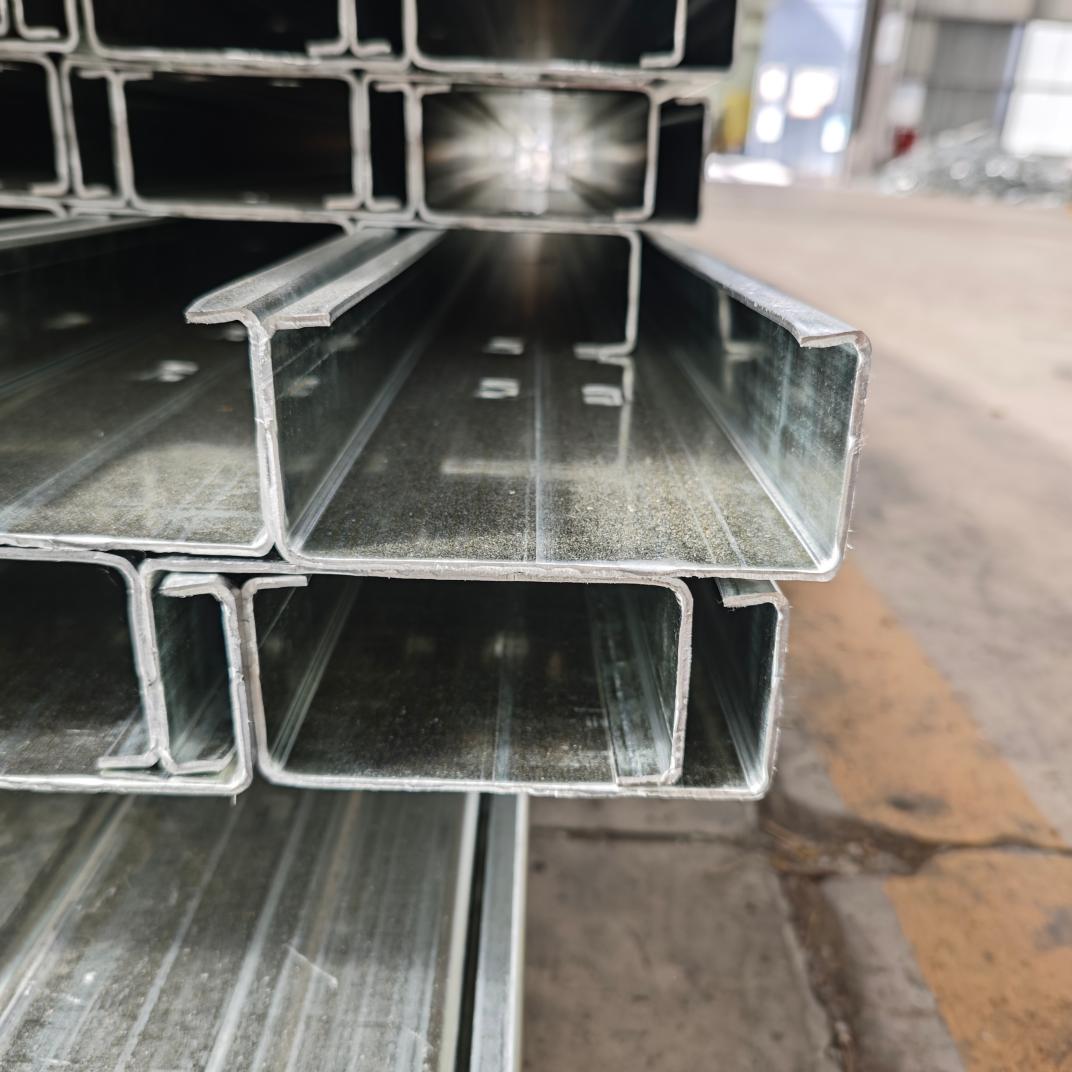

In the realm of Painting Galvanized Steel, our commitment to quality and durability stands out. As a premier exporter from China, we offer exceptional solutions tailored specifically for your needs. Our state-of-the-art factory utilizes innovative methods and high-quality paints to provide a long-lasting finish for galvanized steel structures. Understanding the importance of reliability and efficiency for B2B purchasers, we focus on achieving consistent results with every order. Partnering with Tangshan Jinxuan Supply Chain Management Co., Ltd. means having a dedicated team that is well-versed in your market and unique requirements. Whether you operate in construction, manufacturing, or any other sector utilizing galvanized steel, we offer competitive pricing coupled with outstanding service. Together, we can enhance your projects with robust and beautifully painted galvanized steel materials!

Practical StrateGIes for Painting Galvanized Steel For the Current Year Guarantees Peak Performance

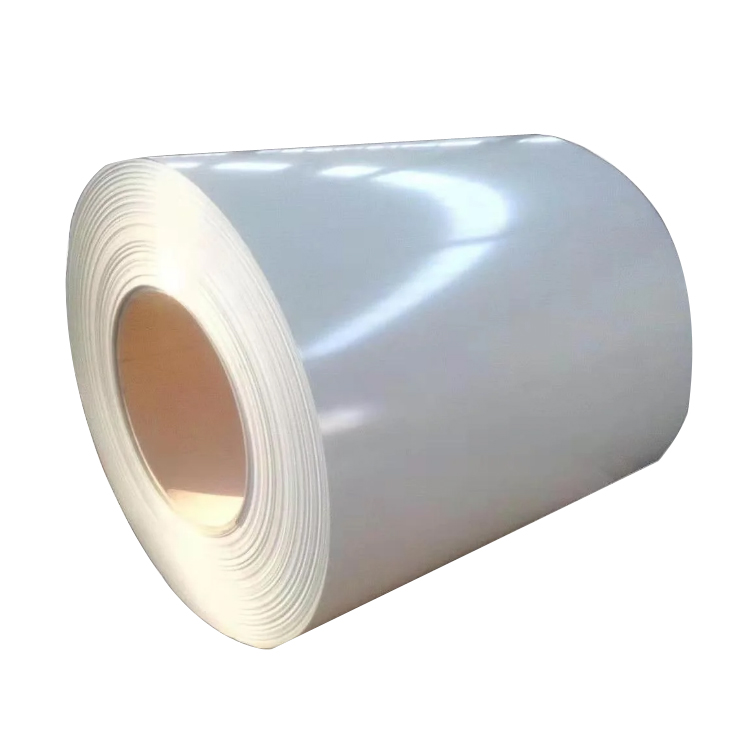

In the ever-evolving landscape of the global Steel Industry, ensuring peak performance in painted galvanized steel is crucial for buyers looking to maintain competitive advantages. At Jinxuan, with over 20 years of experience, we understand that selecting the right painting strategies can drastically affect durability and aesthetics. To optimize the performance of painted galvanized steel, it’s essential to prioritize surface preparation, select suitable coatings, and apply them under appropriate environmental conditions. Effective surface preparation involves cleaning and passivating the galvanized surface to enhance coating adhesion. Techniques such as abrasive blasting, chemical cleaning, or power washing can effectively remove contaminants and prepare the surface for painting. Once prepped, selecting high-quality coatings that offer corrosion resistance and UV protection is key to ensuring longevity. The application process should also be carefully managed—temperature, humidity, and curing times can significantly impact the finish quality. As a leading player in the steel industry, Jinxuan is committed to fostering innovation and performance. We believe that by investing in the right painting technologies and techniques, we not only enhance the functionality of galvanized steel but also contribute to a more sustainable future. Our dedicated team is here to support global buyers in making informed decisions that will ultimately boost their operational efficiency and product quality. Together, inspired individuals can build healthier businesses, leading the way in a thriving global market.

Practical Strategies for Painting Galvanized Steel For the Current Year Guarantees Peak Performance

| Strategy | Description | Materials Needed | Estimated Cost ($) | Time Required (hours) |

|---|---|---|---|---|

| Surface Preparation | Clean the surface thoroughly to remove oils and dirt. | Degreaser, Wire Brush | 25 | 2 |

| Rust Inhibitor Primer | Apply a rust-inhibiting primer for better adhesion and corrosion resistance. | Rust Inhibitor Primer | 30 | 1 |

| Topcoat Application | Apply a high-quality exterior paint suitable for metal surfaces. | Exterior Metal Paint, Brush/Roller | 50 | 2 |

| Finishing Touches | Inspect and touch up any missed spots or imperfections. | Paint, Brush | 15 | 1 |

| Maintenance Check | Regularly inspect the painted surface to ensure long-lasting performance. | Inspection Tools | N/A | Monthly |

why choose Painting Galvanized Steel Leads the Global Market Ahead of the Curve

B

Benjamin Hall

I was pleasantly surprised by the quality! The after-sales service personnel were wonderfully knowledgeable and helpful.

30 May 2025

S

Scarlett Rivera

The products are of high quality! The after-sales team addressed my concerns swiftly and professionally.

17 May 2025

N

Noah Fields

Top-notch quality from start to finish! Customer service was knowledgeable and very accommodating.

16 May 2025

P

Picking Casey

Great experience! The items I ordered are of high quality, and the customer service was top-notch.

02 July 2025

G

Grace Lee

Impressive overall! The product quality is top-tier, and the after-sales service was efficient and professional.

19 May 2025

A

Archer White

Fantastic purchasing experience! The quality of the products is outstanding and the customer service was exemplary.

23 June 2025