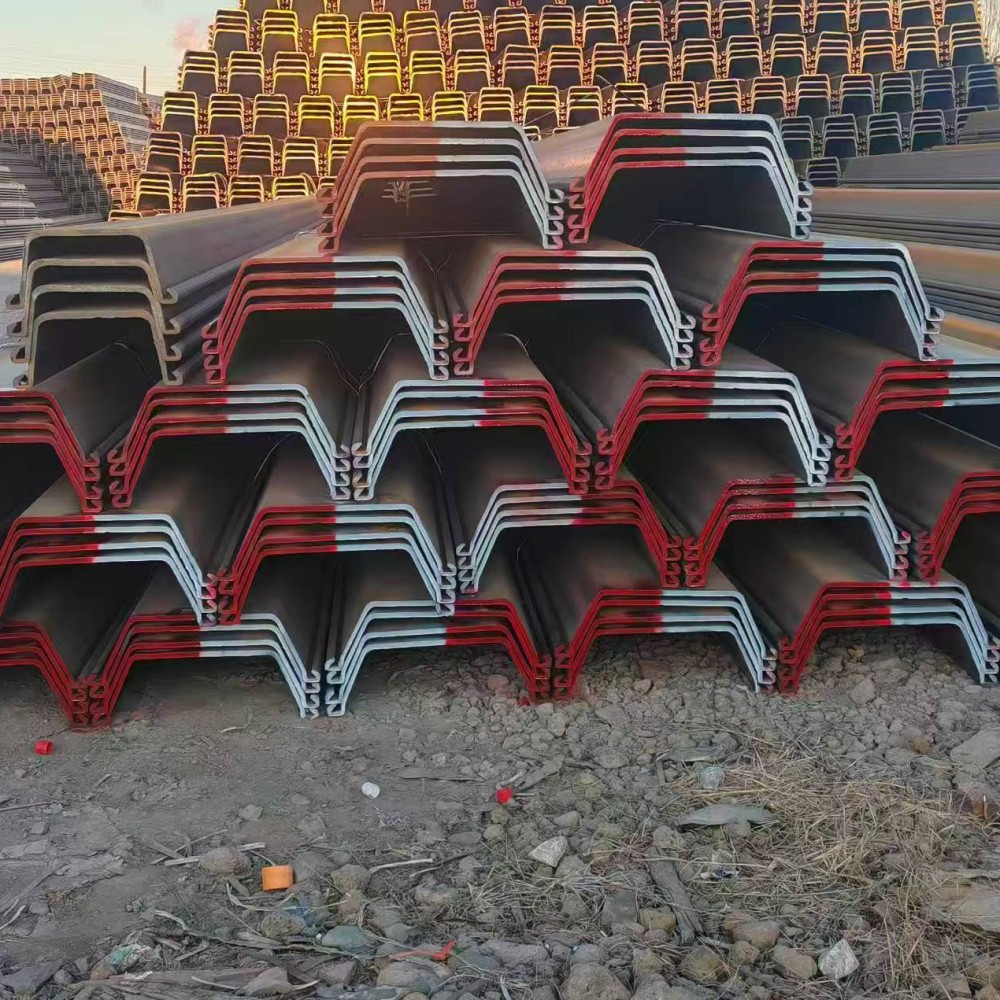

Robust Framework Hot Rolled Steel Sheet Pile

description1

Production description

Product name |

Steel Sheet Pile |

Type |

U/Z sheet pile |

Area |

U type;625-3800cm3/m; |

Z type:1245-5015cm3/m | |

Specification |

U TYPE:U400-750*100-125; |

Z TYPE:Z18-700,Z26-700,Z36-700 | |

Wire weight |

5-50kgs/coil or as customer requirements |

Grade |

Q295P, Q355P Q390P Q420P Q460P,SY295, SY390, SYW295, SYW390 |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

MOQ |

5 tons |

Production process

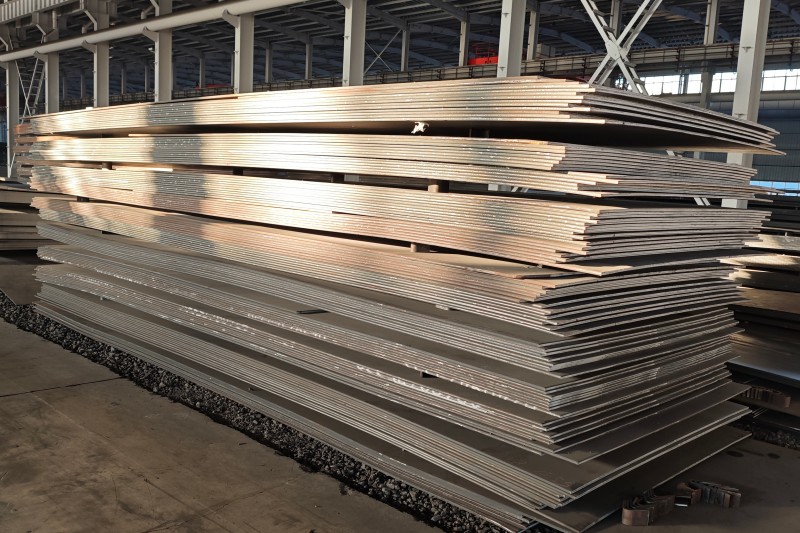

Raw Material Preparation

Select hot-rolled steel coils or plates, ensuring the material meets relevant standards.

Production Process

Preprocessing

Level the steel plates and remove surface scale, oil, grease, and other impurities.

Production Process

Forming

Use cold bending machines or hot-rolling dies to shape the steel into the designed cross-sectional profiles (e.g., U-type, Z-type), focusing on forming the lock structures.

Production Process

Lock Treatment

Weld or perform precision machining on the lock parts to ensure tight connections and smooth interlocking.

Production Process

Straightening and Alignment

Adjust dimensional accuracy and straightness to ensure the overall shape meets requirements.

Production Process

Surface Treatment

Conduct derusting (e.g., sandblasting) and anti-corrosion coating (e.g., painting, galvanizing) to enhance durability.

Production Process

Quality Inspection

Test dimensions, mechanical properties (tensile and bending strength, etc.), and lock fitting; products are shipped after passing inspection.

Production Application

Footwear abrasion solutions

● Construction Engineering: Used for foundation pit support (ensuring the safety of foundation pit construction in complex environments) and basement construction (bearing the external pressure and creating a working environment).

● Water Conservancy Engineering: Applied in river regulation (preventing riverbank collapse and facilitating ecological slope protection) and flood control dams (temporarily built to resist floods).

● Transportation Engineering: Suitable for road and bridge projects (enclosure and water stopping during the construction of bridge abutments and pier foundations) and tunnel engineering (slope support at the entrance and exit of tunnels).