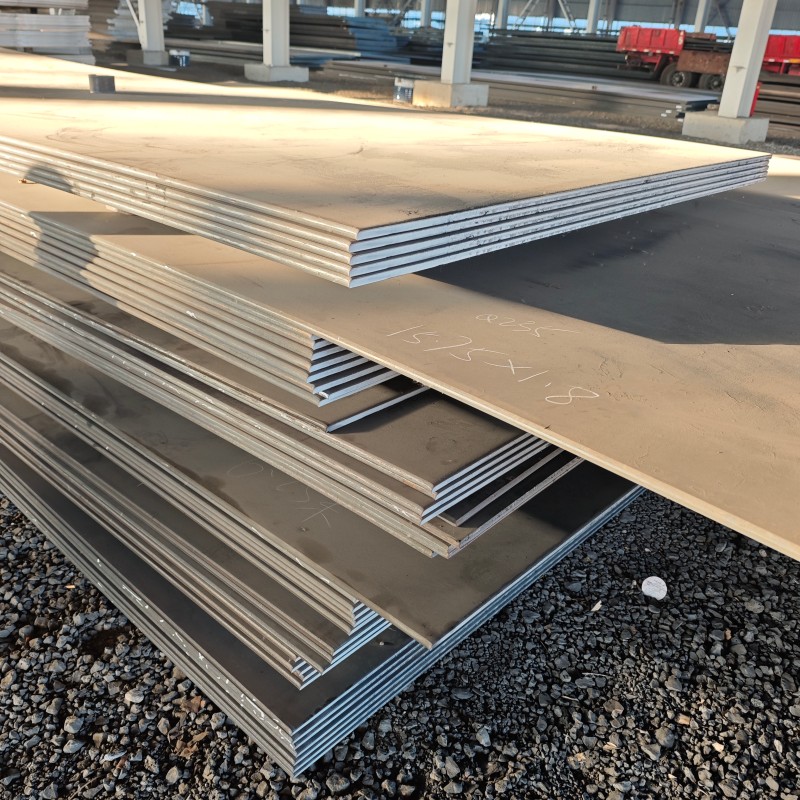

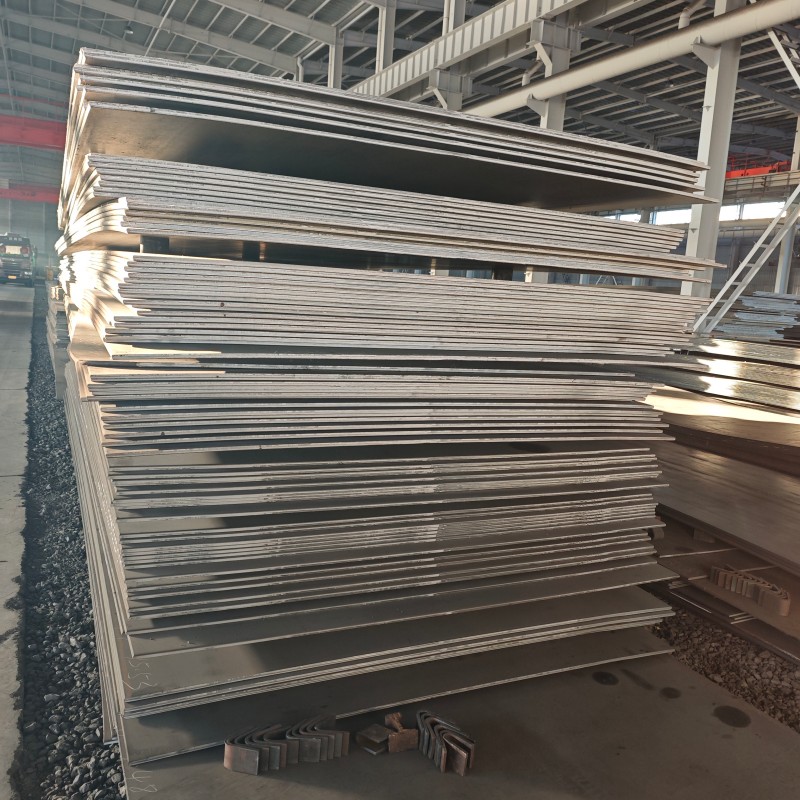

Strict Quality Control Standard customized Hot Rolled Steel Sheet

description1

Production description

Product name |

HOT ROLLED STEEL PLATE |

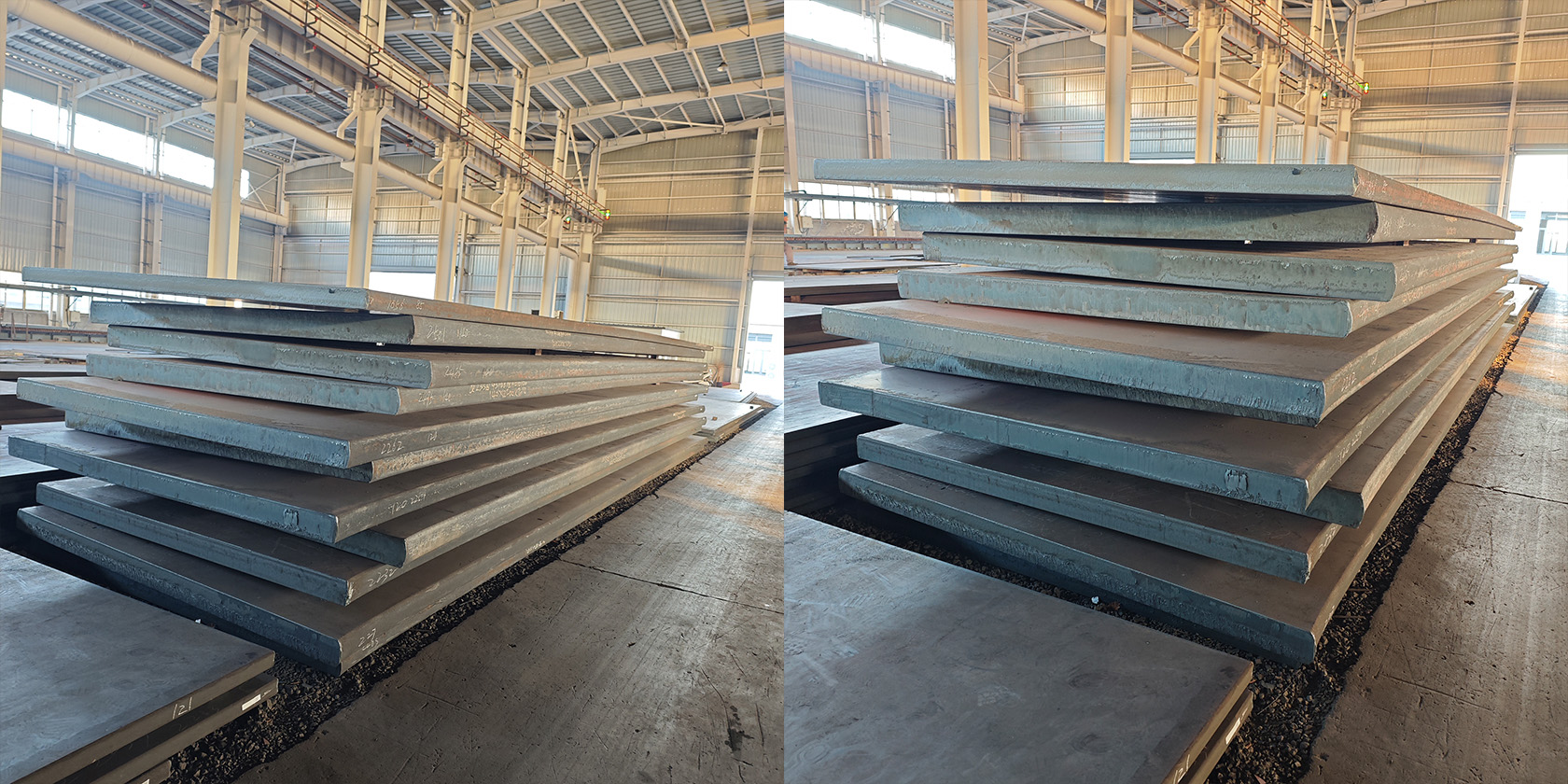

Thickness |

2.75mm-400mm or according to customer's special request |

Width |

1500mm-2500mm or according to customer's special request |

Length |

1m-12m or according to customer's special request |

MOQ |

5 tos |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Grade |

Q235B,Q235C,Q355B,Q345R |

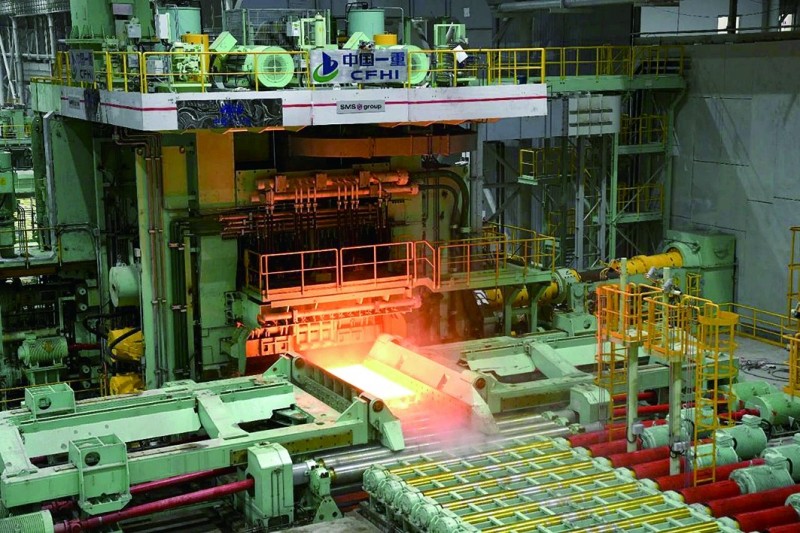

Production process

Heating

Steel slabs are placed in a furnace and heated to a high temperature, making them soft and malleable, ready for further shaping.

Production Process

Rolling

The heated slabs are fed into rolling mills. Through a series of rolling operations, they are compressed and flattened to achieve the desired thickness.

Production Process

Cooling

After rolling, the sheets are quickly cooled. This rapid cooling process helps to establish and stabilize their mechanical properties.

Production Process

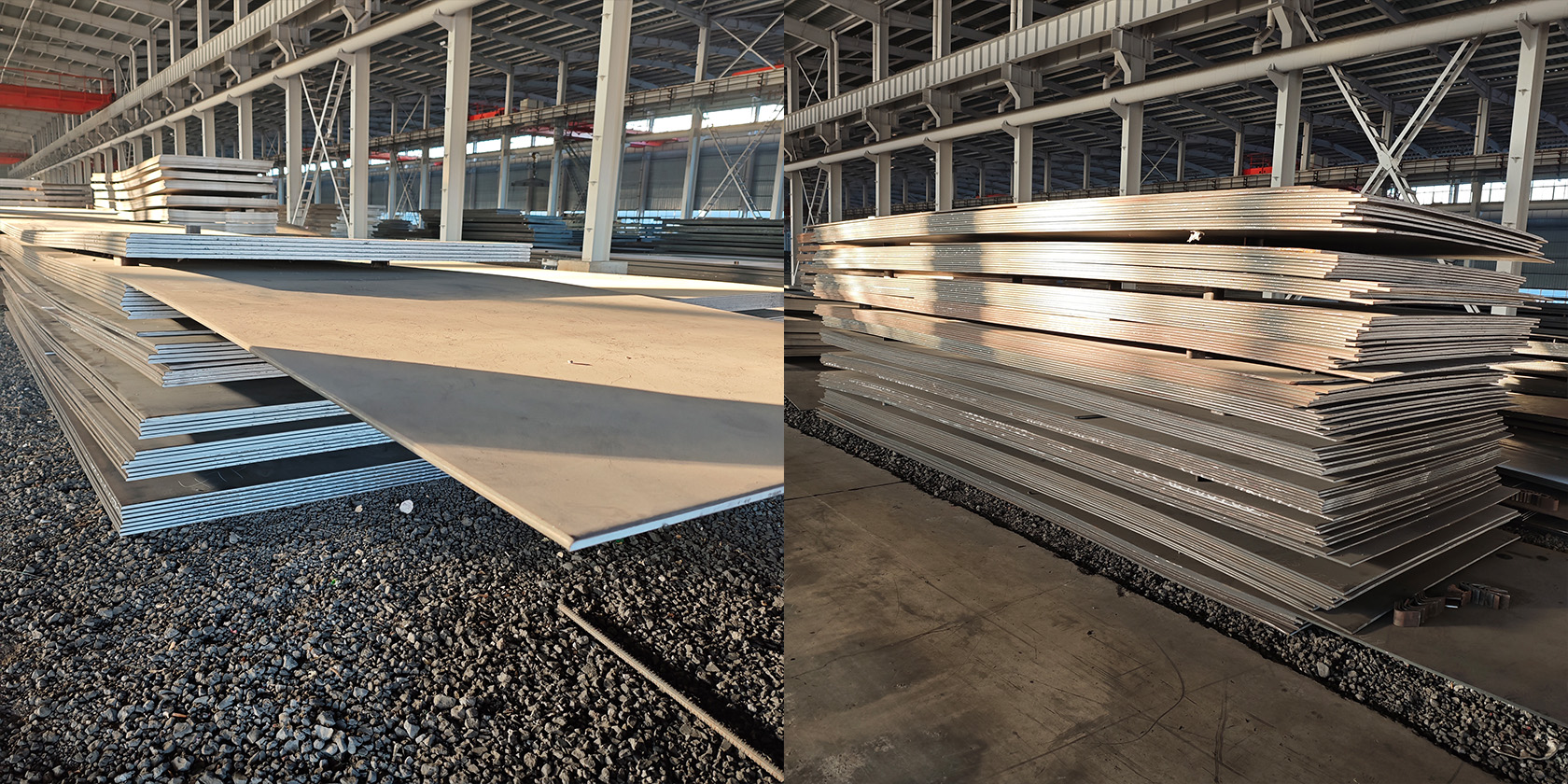

Cutting and Inspection

The cooled sheets are cut into specified lengths. Subsequently, they undergo strict quality inspections to ensure they meet the required industry standards.

Production Application

Footwear abrasion solutions

● Construction Field: Applied to the roof trusses and beam columns of steel structure buildings, roof panels and wall panels, as well as the main beam of the bridge.

● Automobile Manufacturing Field: Capable of manufacturing body structural components such as car doors and engine hoods, as well as automotive parts like frames and axles.

● Mechanical Manufacturing Field: Can be processed into mechanical parts such as gears and shafts, and is also used for the production of equipment casings like machine tool beds.

● Other fields: Container manufacturing, shipbuilding, hardware products