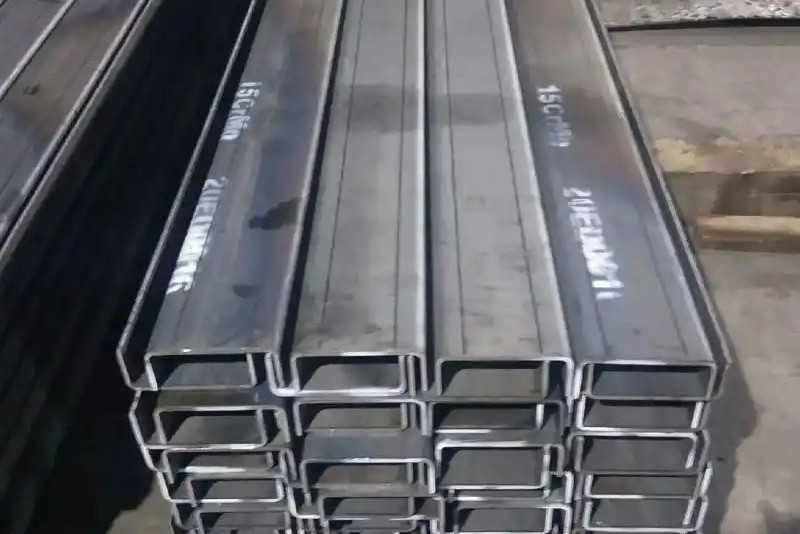

Wholesale Direct Sales Raw Material Hot Rolled U Channel Steel

description1

Production description

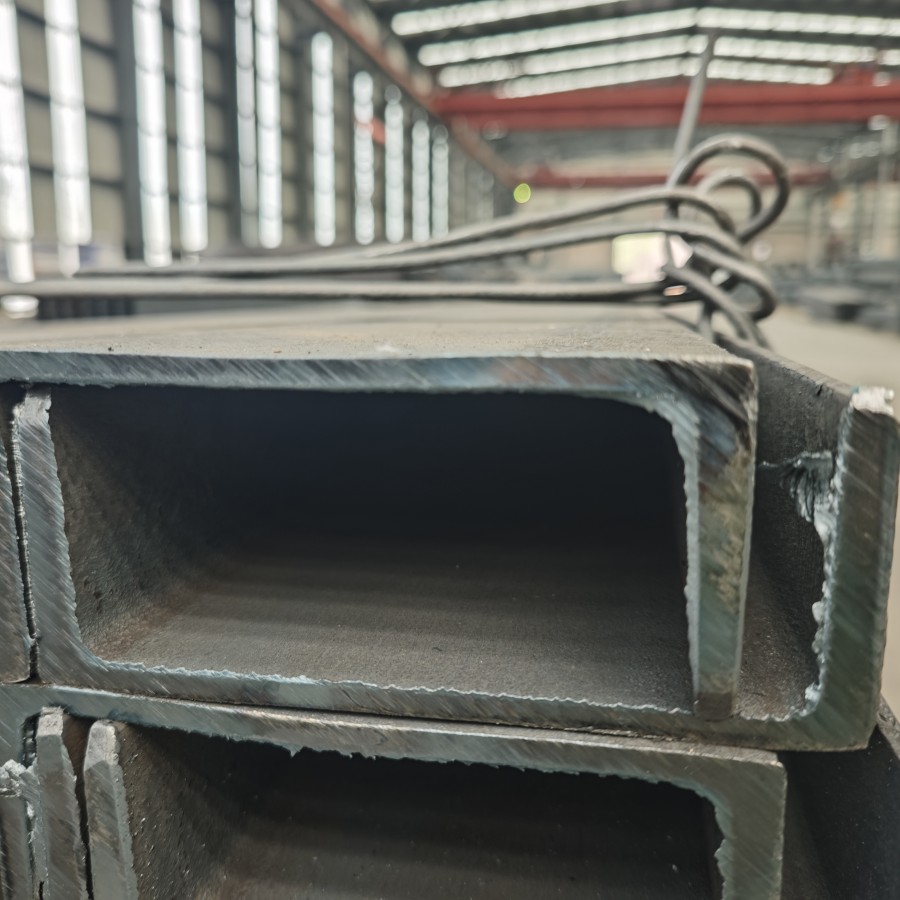

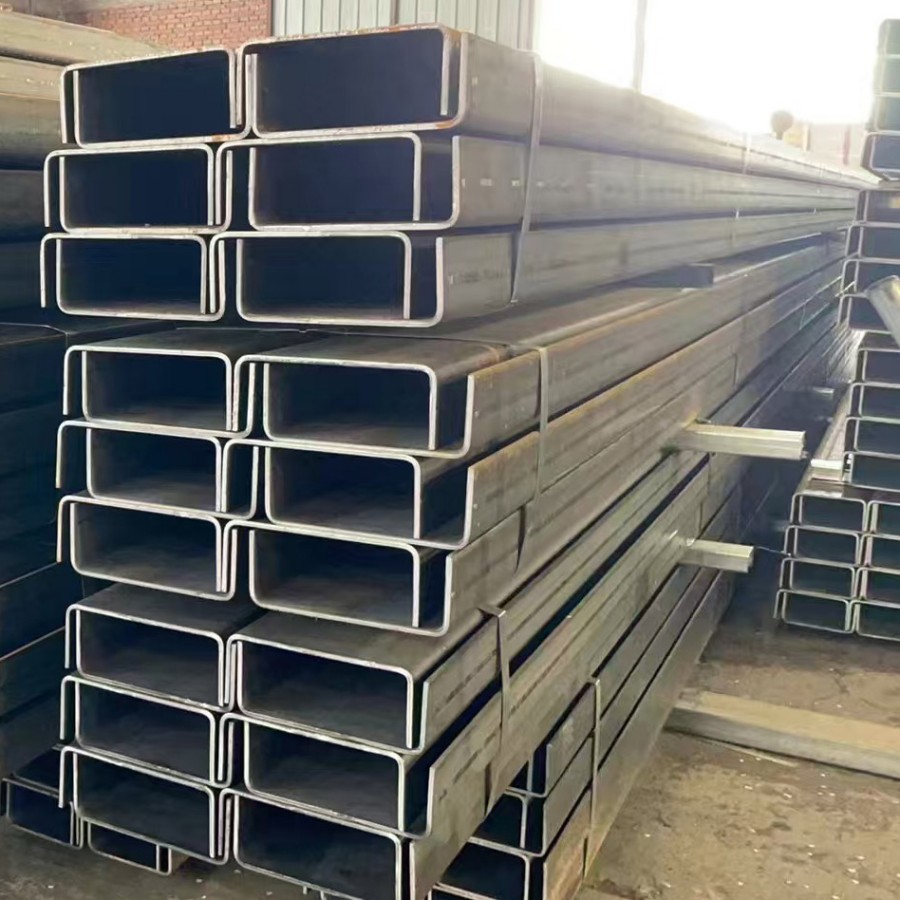

Product Name |

U Channel steel |

Web height |

50-400mmor According To Customer's Demends |

Web Thickness |

4.5-14.5mmor According To Customer's Demends |

Flange width |

37-104mm or customize according to customer requirements |

Length |

6m-12m or According To Customer's Demends |

Grade |

Q235B,Q355B |

Standard |

ASTM,DIN,JIS,BS,GB/T,EN |

Technique |

hot rolled |

MOQ |

5 tons |

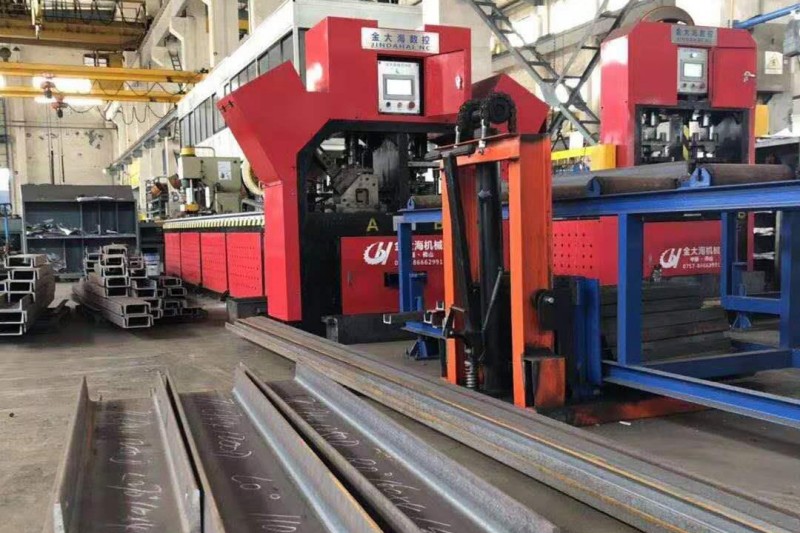

Production process

Raw Material

Select carbon structural steel or low-alloy high-strength steel billets and rigorously check their chemical composition and physical properties.

Production Process

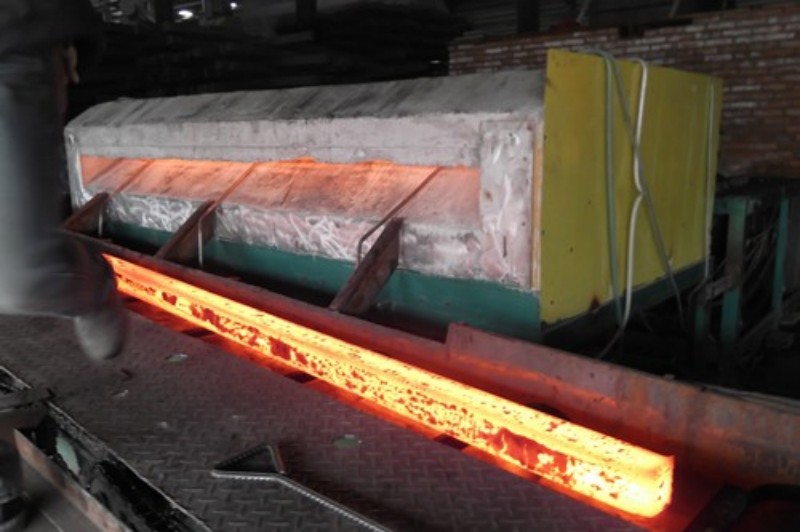

Heating

Heat the billets in a furnace at 1100-1200°C to increase plasticity.

Production Process

Rolling

Rough roll for initial shaping and then finish roll for dimensional accuracy and good surface quality.

Production Process

Cooling

Cool naturally or by forced methods (water or air cooling), controlling the rate to prevent defects.

Production Process

Straightening

Use pressure, tension or roller methods to straighten and ensure straightness and flatness.

Production Process

Cutting

Cut to the specified length with a flame cutter, plasma cutter or sawing machine as needed.

Production Process

Surface Treatment

Enhance corrosion resistance and appearance via hot-dip galvanizing, electro-galvanizing or painting.

Production Process

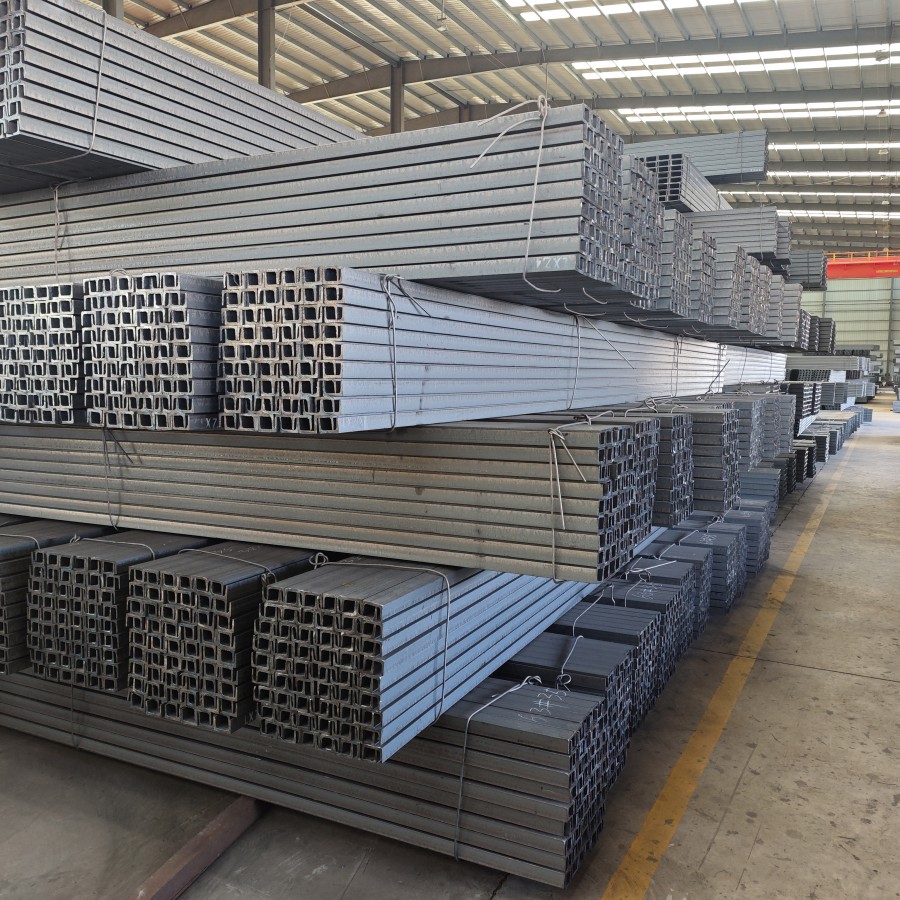

Inspection & Packaging

8.Thoroughly inspect dimensions, appearance and mechanical properties. Package as required after passing the inspection, then store or deliver.

Production Application

Footwear abrasion solutions

1. Construction: Building frames of industrial plants or Structural support in high - rise buildings.

2. Mechanical Manufacturing: Frames and bases of machinery.

3. Transportation: Vehicle frames or Ship deck supports.

4. Warehousing and Logistics: Warehouse rack construction.